Why should I avoid negative inventory levels in inFlow?

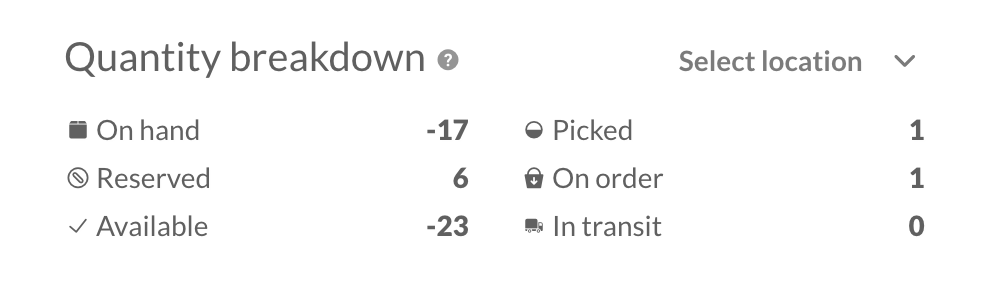

Negative inventory in inFlow occurs when the quantity on hand of a product is less than zero. (ex., a Quantity on hand of -17 at Location A).

We recommend that you avoid negative on hand quantities wherever possible.

You can learn more about how inFlow calculates quantity on hand and other quantities from the quantity breakdown guide.

How can negative inventory affect inFlow’s performance?

Just like how you can’t actually have negative stock on your physical shelves, inFlow’s internal calculations aren’t designed to support negative stock levels.

It’s okay if inventory levels temporarily dip into the negative, but if you consistently have products with negative inventory, this can cause inFlow to have performance issues.

Negative inventory affects performance because, in the background, inFlow is constantly calculating your product costs based on the negative amounts. These calculations are happening even when those products aren’t on active orders!

That’s because inFlow calculates your product cost continually with every transaction (unless you use manual costing). Maintaining consistent negative inventory across your products created inFlow has to do a lot of extra work to calculate your cost, which can really slow things down.

How can I check for negative inventory levels?

Reports provide an easy way to check on your inventory levels.

You can head to Main Menu > Reports > Stock Levels and generate the Inventory by Location report. This report groups all of your products by location, and you can select the Quantity column to make it easier to find any negative numbers.

I use sublocations to divide up my POs by lot # so that I can track product for food safety recalls. Once I started doing this, I started getting negative inventory. Not really sure if my inventory is correct now.

1) Is there a way to avoid inventory to go in to negative, or in short, not able to generate a NEGATIVE sales order.

2) Any possible way to use a thermal printer

Using inventory by location report does not seem to generate the negative quantities.