Key takeaways

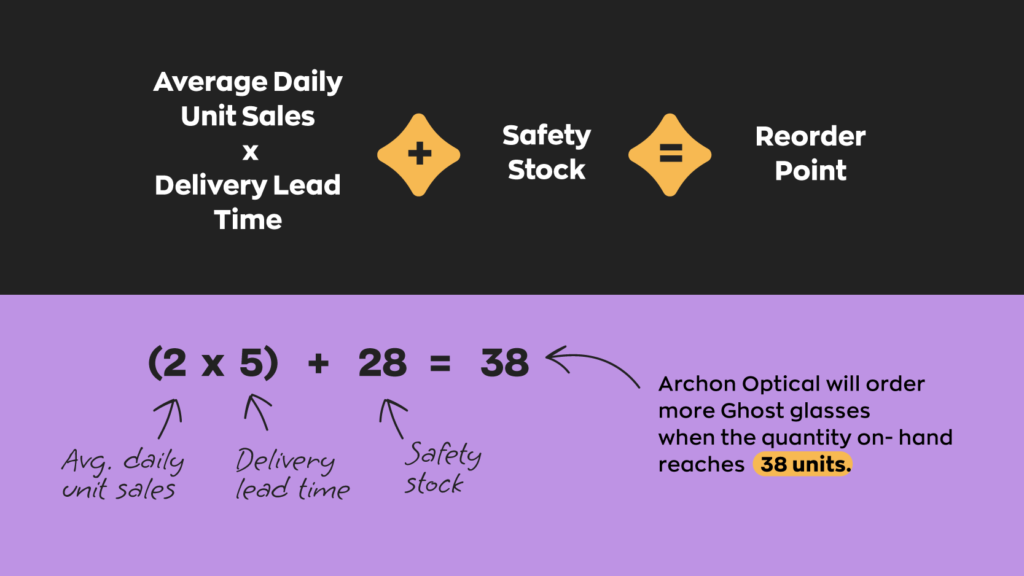

- The reorder point formula is: (average daily unit sales × delivery lead time) + safety stock.

- Businesses that use reorder points see a reduction in stockouts and overstocking, which reduces unnecessary shipping costs and improves inventory forecasting.

- You can calculate average daily sales by dividing the total units sold over a specific period by the total number of days.

- Average delivery lead time is determined by tracking past purchase orders, considering variations due to order size or seasonality. It can be calculated by adding up the total lead time in days over the past 6 months to a year and dividing by the number of shipments.

- Safety stock is an integral part of proper inventory management. It accounts for unexpected spikes in demand or shipping delays. You can calculate your safety stock by calculating the difference between maximum and average lead times.

- Combining accurate reorder points with safety stock helps optimize inventory flow, reducing costs and improving customer satisfaction.

No matter what type of business you’re in, it’s essential to maintain healthy levels of key inventory. Stockouts can lead to lost sales, diminished customer trust, and a tarnished brand reputation, while overstocking ties up capital and potentially incurs additional storage costs.

This is why it’s important to calculate accurate reorder points for your inventory. By correctly determining when to replenish inventory, your business can maintain a smooth operation, meeting customer demand promptly and efficiently. However, before getting started, it’s crucial to understand exactly why reorder points are useful and what information is needed to calculate them.

Reorder point calculator

Are you trying to figure out the reorder point for your items? Calculating reorder points manually can be tedious, especially if you’re doing it for multiple types of inventory. Fortunately, instead of doing the math yourself, you can just plug some numbers into our reorder point calculator!

Reorder point calculator

What is a reorder point?

The reorder point is the minimum stock level a specific product can reach before you’re prompted to order more inventory. In other words, it lets you know the lowest stock level you can hit before you need to place a new order.

A reorder point is not a static number; it’s based on your purchase and sales cycles and varies by product. Once you have a handle on the inventory turnover patterns of a product, you’re ready to start putting the variables together.

The reorder point formula and how to calculate it

The formula and calculation for a reorder point work out like this:

(average daily unit sales x the lead time in days) + your safety stock = your reorder point

This formula takes three things into account. The first is how quickly the item is selling. The second is how long it takes to get more of that item. And finally, the third is the safety stock you should keep on hand, just in case. To illustrate, we’ll look at each of these variables in a little more detail:

Calculating average daily unit sales

The average daily unit sales is the quantity of an item you sell daily. To calculate this, take the amount of how much the item sells and divide it by a certain time period.

For example, if you sold 500 basketballs in a month with 31 days, your average daily unit sales would be 500/31, which amounts to 16.12 basketballs each day. You don’t have to round to an even number, and selling less than one unit a day is perfectly fine. Conversely, if you only sold 10 basketballs in a 31-day month, your average daily unit sales would be 0.32 basketballs a day.

Calculating lead time in days

The lead time is the amount of time in days it takes from when you order stock to when it’s delivered to you. To calculate this, look at your past purchase orders and see how long it took for the items to arrive at your door.

For example, let’s assume that of your past 10 shipments, 5 took 3 days to arrive (3 days x 5 shipments = 15). The other 5 shipments took 4 days to arrive (4 days x 5 shipments = 20). If you add up all those days and divide them by the number of shipments, that’s your lead time.

In this example, take 35 and divide it by 10 — this results in a lead time of 3.5 days. The lead time doesn’t have to be exact; you just have to base it on your experience.

Calculating safety stock

Safety stock is what you keep on hand for those “just-in-case moments.” For this reason, you should think of this as the minimum amount of stock you want to be available in your inventory.

The formula for calculating safety stock is as follows:

(maximum daily sales x maximum lead time) – (average daily sales x average lead time) = safety stock

To illustrate, we’ll continue to use the basketball example. Let’s say that your historical data shows your top sales on basketballs in a single day was 4, and the longest you waited for a shipment was 10 days (4 x 10 = 40).

You also calculate that your average daily sales over a year for basketballs is 2, and you wait, on average, 6 days for a shipment to arrive (2 x 6 = 12). In this case, your safety stock would be 28 (40 – 12 = 28).

When setting your safety stock, you should also consider certain things like delivery delays, seasonality, or damage due to inventory transit. Just like the lead time, look at your past purchase orders and see what factors usually affect the delivery time of your items, and adjust your safety stock accordingly.

The reorder point formula video

If you’re the type who likes to watch instead of read, we’ve created a video version of this post. The examples are slightly different, but the formula is the same. Peter covers the reorder point formula in just three minutes:

Why is the reorder point calculator so valuable?

There are several reasons why it’s important to know your reorder point for each and every one of your products. Here are just a few reasons why it’s so important:

- Prevents stockouts: Stockouts are a business’s worst enemy. Not only do they result in lost sales, but they also lead to dissatisfied customers. By using a reorder point calculator to improve inventory accuracy, businesses can ensure they can always meet customer demand.

- Prevents overstock: The flip side of stockouts is carrying excess inventory. The carrying costs associated with excess inventory add up more quickly than you may realize — they’ll also eat into your bottom line while undermining efforts to reduce your environmental impact.

- Reduces disruptions: If you’re a manufacturer, running out of inventory could potentially cause your operation to come to a screeching halt. For this reason, a reorder point calculator can be helpful to minimize the amount of downtime you experience.

- Reduces waste: Every industry could benefit from reorder points, but none more than those dealing with perishable goods. Proper reorder points could save you thousands on potential waste if you’re managing inventory with a lot number, batch number, or expiration date.

- Lowers shipping costs: By setting proper reorder points, you can avoid the need for frequent orders, which will save you in shipping costs over time.

- Improves forecasting: With accurate reorder points, you’ll be able to anticipate your business needs, ultimately leading to less rushed orders or last-minute panic buying. Overall, your demand forecasting will improve.

Something to note — reorder points are great, but they’re just one part of a much larger picture. For well-rounded inventory management, you should also consider implementing things like cycle counts and barcodes.

What can I do with a reorder point calculation?

Now that you know the reorder point formula, you can use software to show you exactly when you need to order more. While you might be able to create something yourself using an inventory template, inFlow makes managing your stock much more effortless. inFlow has a Reorder Stock screen that lets you know what you’re running low on and how much to reorder.

Managing inventory across multiple locations? No problem. inFlow has the power to set different reorder points based on location. This allows your individual locations to have more autonomy when reordering and still enables you to track your inventory company-wide.

How do I set up reorder points?

Reorder points are vital to keeping your business running smoothly, but they’ll only work if you’re prepared to reorder on time. You can set up a formula somewhere in your inventory list with the reorder point formula, so you can make quick calculations for your products individually.

If you’re a spreadsheet user, you can use conditional formatting for the quantity value of specific cells. You can set Excel or Google Sheets so that cells turn red when they hit a reorder point. This will effectively warn you when you need to start on a new purchase order. You can also set up a formula somewhere in your inventory list with the reorder point formula, so you can make quick calculations for your products individually.

We know it can be challenging to keep track of all these formulas, so we decided to create a handy Inventory Formula Cheat Sheet with 7 of the most common formulas, which you can download for free anytime.

We also have a plethora of free-to-download Excel inventory templates, so be sure to check those out if you track your inventory on spreadsheets.

Reorder faster with inFlow

Unlike spreadsheets, inFlow was designed specifically for working with inventory. Quantity and reorder point fields are built into the software, which prevents errors and saves our customers a lot of setup time. inFlow also has a Reorder Stock window, which identifies which products need reordering, and creates new purchase orders with just one click.

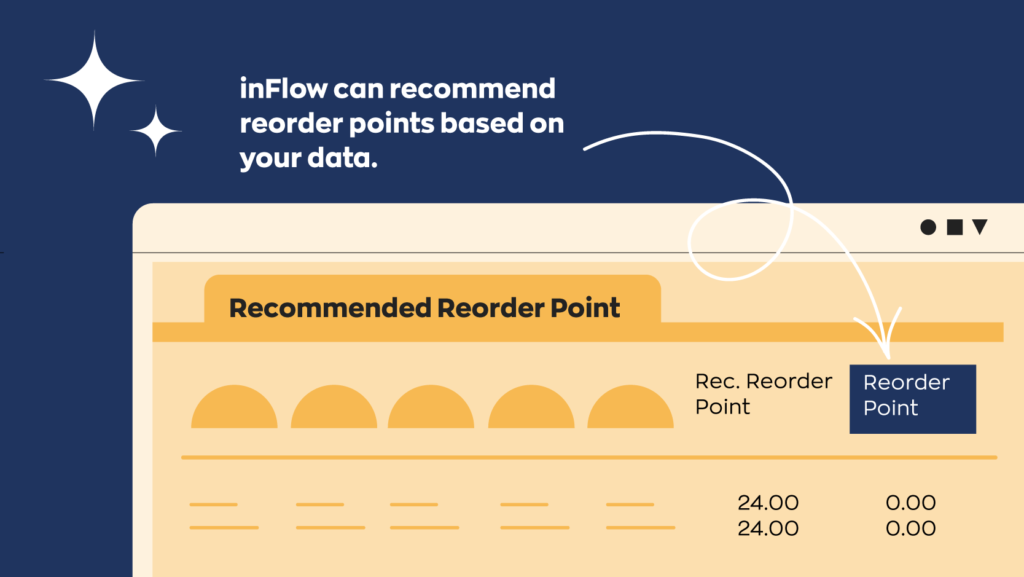

If you’d like to implement reorder points with tailored suggestions for your business, we can help with that too! inFlow has a Recommended Reorder Point report that examines your sales data and recommends reorder points for your products. It also factors in goods in transit (GIT), which are products that have been ordered from a vendor but haven’t been received yet.

Whether you’re just starting out with reorder points or fine-tuning them, inFlow can help! With inFlow, there’s no need for the reorder point formula at all. The best part is that using inFlow can help with so much more than just reorder points.

inFlow integrates with over 95 different applications, such as Shopify, Amazon, and QuickBooks Online, to name just a few. If you want to set up a complete barcoding system, inFlow can do that too! Read our Ultimate Barcoding Guide to learn about barcodes and how to start barcoding your business.

Thank you

It was helpful article

Article Feedback*thanks alot

What is safety stock?

Good question, Amalina. We’ll be writing a more specific article on safety stock in the future, but the quick answer is: it’s the amount of extra stock that you keep on hand to ensure that your business is unaffected by shortages in supply (for example, if your purchase order is delayed by two weeks). It’s like a rainy day fund, but for inventory.

[Update: our safety stock article is now published at https://www.inflowinventory.com/blog/how-to-calculate-your-safety-stock/ ]

Hi, please can you tell the difference between minimum stock level and the safety inventory? If there is and difference whats the essence of knowing the minimum level then? Thank you

Hi Michael, the reorder point basically becomes your minimum stock level, because you’ll want to reorder once you fall *below* the reorder point. So if you had a reorder point of 20 and you reached 18 or 19 pcs on hand, you’d want to reorder. You’d be below your minimum stock level.

Safety stock is calculated as part of that reorder point, the more safety stock you decide on, the higher your reorder point will be.

Many Thanks

Hey man,

You could only have 29.54 stock left if someone ordered .46, not .54 as you wrote in the article!

Hi Tom, thanks for pointing this out! Sorry about that — we’ve made the correction in the post.

– Thomas

Question.

The following is the consumption of rice in certain hotel.

maximum consumption=6000kg per week.

minimum consumption=4000kg per week.

Reoder period 4-6 weeks

Reorder quantity 30,000kg

Calculate

i)Re-order period.

ii) Minimum stock level.

iii)Maximum stock level

iv)Average stock level

How can i calculate this?

Hi Boniface! Sorry, this post doesn’t deal with max stock levels, but rather the minimum threshold before you *should* reorder.

If you’re looking for a min/max approach, you might need a different article for this question (I did a quick search, and this one may help: https://www.lokad.com/min-max-inventory-planning-definition).

Its too good and very easy to understand thank u very much for this good efforts dear.

Under my area working for a state agency in South Carolina, I have a main warehouse and four smaller sub-warehouses. The smaller warehouses serve specific facilities for the agency and order FROM the main warehouse.

Can your system operate reorder points for all of the five warehouses?

Thanks

Hi Chuck,

Sorry for the late reply on this! At present, inFlow’s reordering is company-wide. You can set reorder points for specific products, but reordering would only trigger when you drop below a company-wide stock level of X (not per location).

If I understand you correctly, you’d find it more useful if these sub-warehouses could have their own reorder points. This is something we’re taking into consideration for future updates to inFlow, so I’ve added your vote to the list! If this changes, we’ll make sure to get in touch with you via email to let you know!

Hey Thomas, very nice article. Please ping me back I would like to discuss more about this.

Many thanks..my query is..

where or how was 14 arrived at in determining the safety stock?

Thanks!

Hi Ramon, the 14 days was a simplified estimate based on having two weeks of stock, which is what we’ve seen from other small businesses. However, another way to estimate safety stock is to think of it as a percentage of your lead-time demand. We go into a bit more detail about that in this article: https://www.inflowinventory.com/blog/safety-stock-calculation/

Dear,

first of all I am really thankfull to you for this detail information.butt my question is that how can we decided to purchase or manufacture quantity for stock(like minimum or maximum level)

The article was extremely good.it was very useful to me….

Regarding safety stock,I have a small doubt ..why could we take up 14 days stock as safety stock,?

EXPLAIN THE ROLES OF JIT AND TQM AND SUPPORTIVE SUPPLIERS RELATIONS PLAY IN MORDEN MANUFACTURING

Hi Talent, thanks for reading! We’ll take those under consideration for future topics on the blog!

educative

Hi Thomas, I would like to set up par levels for a restaurant where the deliveries are made to the restaurant on a daily basis and I do have the historical usage of product for every day of the week. The goal is to have enough product at the store to meet the demand but at the same time not have too much product sitting at the store how do I achieve this?

Hi Charantej, good question!

For reordering, it’s really a balancing act. Since you have the historical usage data already, you can calculate an average daily unit sale and then factor in your lead times — basically following the formula in the article at that point.

One point I didn’t touch on in the article was the safety stock for items with a short shelf life, like food.

Depending on the time of ingredient, it might only last a few days, so you might have to think about a safety stock levels in terms of days (instead of ~ two weeks like the article suggested).

After that it’s really just about watching the low points in your inventory at the end of each day. If you’re constantly running too low on an item by the end of the day, you can increase its safety stock levels.

WHAT IS THE FORMULA FOR EOQ

Hi there! Sorry, we don’t have an article on EOQ at the moment, but I’ll definitely consider it for the future on our blog!

How to determine minimum reorder level for sand.

Hi Wisdom,

We don’t have any on-hand experience with reordering sand, but I’d imagine it would be done by volume or by weight, and you can set up units of measure within inFlow: https://www.inflowinventory.com/support/cloud/what-if-i-sell-my-items-in-a-different-unit-than-i-purchase/

Once you’ve set those up, you can set up a reorder point that uses the unit of measure you specify: https://www.inflowinventory.com/support/cloud/is-there-a-way-to-reorder-items-that-are-low-in-stock/

Hi Thomas Wong,

Helpful article. Please describe with example for setting up automatic reminders for reorder points by Excel.

This is new formula. Can be applied this formula for arrivals of tourists?

Hi Vijay, this formula is meant to help you reorder stock of physical goods before you completely run out, it isn’t necessarily meant to be applied to how many tourists might be visiting a place. I think you might have to google for another kind of formula for that, sorry!

There is also a term Goods In Transit(GIT) which is subtracted from this ROL formula but its not here.how can we calculate GIT??

Hi Sanila, sorry about that, this post doesn’t include GIT as part of this formula.

But our software, inFlow Cloud, does track the status of products on order: these are products that have been ordered from a vendor but haven’t been received yet. And once you set your reorder point, inFlow will also take the goods in transit into account when suggesting what to reorder.

it was helpful

We have consumption data and lead time for the product. Now we want to calculate minimum inventory level, Maximum inventory level, and Reorder level.

Hi Mahesh, sorry, this article covers the reorder point (level) specifically. But thank you for the feedback, we’ll consider those other two topics (min/max inventory) for other articles!

Hi. Very Nice Article and very Helpfull (my english not great)

I AM EMPLOYEE IN A COMPANY. THAT HAVE 1000 OF ITEMS

TODAY BOSS QUESTION ME HOW TO A CHECK ON REORDER LEVEL in software that we use. Software have report (Stock Less then reorder level).

But Boss need that how can we check items that come near to reorder level means item reorder level is 500 and he says that when item quantity is near to 600 then u report me about this. how can i do this.

thanks alot

Hi Mustafa, thanks for the feedback!

As for the question: you could set up a spreadsheet cell with conditional formatting that could turn a certain color as you get close to the reorder point, but I’m not aware of any software that does this (including inFlow).

Rather it sounds like your boss might want a reorder point closer to 600 rather than 500, if that’s really the level that he’s worried about. Or the other thing you could tweak is how much you reorder at a time (the reorder quantity). If you keep hitting your reorder point quickly, then maybe the business could try reordering *more* product at a time.

Sorry I couldn’t be more definitive with the response, but I hope that helps!

What is reorder point formula if lead time is more than cycle time?

Hi, great formula.. its helpful

May i know how if I have 3000 different items? is there another way to count the reorder point?

Hi Christy, good question!

We actually have a new report in our software, inFlow Cloud, that helps with this. It can take your sales numbers into account, as well as the lead time, and can suggest reorder points for your products. We’ve got more information on the feature here: https://www.inflowinventory.com/support/cloud/can-inflow-recommend-a-reorder-point-for-my-products/

And if you’d like to try inFlow out for yourself, you can do so for free from here: https://www.inflowinventory.com/signup

Nice article sir.

Wow, that was a great piece of article out there for a grab. I’m glad to have read this. Thanks for the thorough explanation.

Good article but the report used is not available on the desktop version, unless there is an update I am missing.

Hi Gabriel, sorry we missed this one. The Recommended Reorder Point report is a new feature we’ve added to inFlow Cloud for Windows in the past few months. I’m afraid that feature is not present in inFlow On-Premise, but the Reorder Stock window that we mention is available in both versions of our software.

Good Morning,

Dear Sir Thomas, This is Eric from Philippines.

1st of all this tool is very helpful for us, but I would like to ask question, How to calculate the quantity to be ordered after reaching the Ordering point?

Hoping for your reply

Best Regards

Eric

Hi Erico, the reorder quantity can often be dictated by which vendor you’re buying from. Many vendors can have a minimum order quantity (MOQ), and our software, inFlow Cloud, has a spot specifically so that you can input the reorder quantities.

Very nice explanation. Thank you Thomas.

What type of materials to be considered in min max category.

Hi Thomas. Very nice article. But can you tell me how much should we order for the next batch when we hit the reorder point, as i get confused with other articles in the internet. So after i get to the reorder point how much shall i order?

Hi Shashank,

Our software, inFlow Cloud, can help with how much you should reorder based on your sales and inventory levels.

But if you aren’t using our software yet, a good starting point would probably be to think about reordering to cover X number of days/weeks.

So when you hit your reorder point, you could examine the average daily sales of that product.

Then, as an example, you could use that average and multiply it by 5 to cover another week’s worth of stock, or 10 to cover two weeks of stock.

You’ll need to tweak that number to suit your business, but having a high enough reorder point should keep you from running completely out of stock while you wait for new orders to come in.

Seams that the system uses the Vendor for lead times and not the item being ordered itself?

If I order the same item from 2 different vendors then how does that work?

If I order for different locations how does that work?

Hi Holly,

That’s a good question and thank you for taking the time to share your thoughts.

You’re correct that our implementation of lead time is at the vendor level and not at the item level, so we cannot currently account for multiple receiving locations or different lead times per item.

We’d like to improve reordering within inFlow in the future, but I’m afraid I don’t have a timeline to share just yet.

I have submitted your feedback to our team along with your email address, so someone from inFlow will get in touch if we have improvements to share down the line.

Thank u

Got idea about re order

Hi. What if there’s a factory production minimum? How do we factor that in? Thanks!

minimum level is 60

re order level is 100,do i need to place an order?

Hi Lesego, the way we’ve defined the reorder point here is to basically treat it like a minimum level. So once you dip below the reorder point (in your case 100), then that is when you should order more stock.

WHAT IF THE SAFETY STOCK IS IN DAYS LIKE KEEP A 2 DAYS SAFETY STOCK?

Fabulous job

Hi Thomas.

I’m a mfgr who used a premier Re-order Point manufacturing software system for many years – MAPICS/IBM – great stuff, can’t say enough about it.

Looking for another system today, but looks like the whole world (mistakenly) has a knee-jerk reaction and blurts out MRP at the drop of a hat. I don’t want an MRP system. OP works just fine. Are you able to recommend any notable such systems on today’s market.

This is also to address the full needs of a small mfg company. Thanks! (good article)

Hi Charlie, I would recommend inFlow Cloud if you do manufacturing and you need to keep an eye on stock levels and reorder points. Our software offers reorder points on a per-location basis, so if you have multiple offices or manufacturing sites, each of them can track stock separately (while still being able to transfer stock to each other). You can see our manufacturing features here:

https://www.inflowinventory.com/features/manufacturing

But if you want an overview of other manufacturing software, Capterra is a good place to start: https://www.capterra.com/

May I know can we use this reorder formula for ordering items for multiples shop from production for donut business.

Hi Yin Yin, yes you could. I’d just recommend using the formula on a per-location basis. Don’t just use it once across all locations.

how do we get the average daily unit sales?

Hi Thomas,

I hope you are doing well. I read your article “Reorder Point Formula and Safety Stock” which was very informative.

I have a few questions related to re-order point but I have not been able to find a good answer to it. Could you please explain what are the different variables that can affect the reorder point or level from within the organization? Or what are the factors that may hamper the warehouse or distribution center from placing a reorder or effect it in any way.

I would appreciate if you can provide me any lead on my question.

Regards,

Babar Masood

Which formula of Re-order point to be used if an organisation has a policy to keep safety inventory?

Hi,

Does order frequency need to be taken into account when looking safety stock settings within the re-order point formula.

Example below:

Sales:

– Jan 120

– Feb 80

– Mar 60

– Apr 97

– May 118

– June 28

Therefore:

– Average 84 units per Month

– Max 120 units per Month

– Lead time 14 days

– Order frequency 7 days

Reorder point = Avg daily sales * lead time) + SS

Reorder point = (2.8*14) + (14*2)

Reorder point = 67.2

Do I need to add any additional safety stock based on whether my order frequency was 1 week or 4 weeks?

Thanks,

Richie

Hi Richie,

Frequency doesn’t need to be taken into consideration when dealing with any of these calculations. Figuring out your reorder point is all about not having to order on a regular basis but instead ordering only when you need product. That way you’re never sitting on excess inventory which can come with added costs. When implemented correctly using reorder points will ensure you’ll always stay at the perfect level of stock without ever dealing with stock outs. Your safety stock will be there just in case you experience any unforeseen shipping delays.

Hope this helps,

Jared

Very impressive, thanks a lot for sharing a helpful post with us.

Hey Mary,

Thanks for reading, we’re glad you liked it! We love helping people out in anyway we can around here 😉

All the best,

Jared

Hi Tom,

How can I account for demand in relatively set multiples? In Maintenance many items are often used in multiples but, given the formula’s basis on average daily usage a Safety Stock value may result in an insufficient quantity.

Example 1: (2) units of an item are used per year and only ‘demanded’ once per year, the average daily value and resulting Safety Stock will be significantly less than (1) and the minimum stock will be set to (1). While the demand frequency is 1/yr, the quantity per demand is actually (2). Can that be baked into the Safety Stock and ROP?

Can I account for minimum projected demand? If item X has not been ‘requested’ in the past 365 days, but when demanded it is know that at least Y quantity will be demanded, 200 for example?

Hi Tony,

If you’re using multiple items in your workflow and they are required they should be factored into your formula. In the example you gave if 2 units are used per year then your demand per year should also be 2. Your minimum stock should be set to a number that will allow you to still operate. If you need 2 units to do maintenance then your minimum stock should be at least 2 units.

Hope this helps,

Jared

Great by all means and a very informative blog. I’ve learned something new today, keep sharing worthy info like this!

safety glasses

Hey michael,

Thanks for reading! Be sure to subscribe to our content newsletter to get updates whenever we post new content.

Cheers,

Jared

Find the reorder point of a product if average weekly demand is 50 units, with lead time of 2 weeks, and standard deviation of demand during lead time is 10 units. Take z= 2:33 (99% service level), [ROP=x+25’d; x=dLT sd sdx Sq Rt (LT)]

thank you for the author .. 🙂 .. Very impressive, and thanks a lot for sharing ideas regarding this articles.

Hey matt,

Thanks so much for reading, and a double thank you for the kind words! We love helping people out whenever we can. If you want to keep up to date with all our new content you can subscribe to our newsletter at the bottom of the page.

Cheers,

Jared

I found this blog post to be very helpful. Thank you for writing it!

Hey Yesnospin,

We’re glad we could help! Please consider subscribing to our newsletter at the bottom of this page to stay up to date with all our new releases.

All the best,

Jared

I found this blog post to be very helpful. Thank you for writing it!

Hey Syllable,

Thanks for stopping by and taking the time to read our blog! We’re super glad we could help.

All the best,

Jared

Consider an economic order quantity case where annual demand D=1000 units, economic order quantity Q= 200

units , the desired probability of not stocking out P=0.95 , the standard deviation of demand during lead time 6L

=25units and lead time = L=15 days. Determine the reorder point. Assume the demand is over a 250 week day year.

Solution:

d = D/no. week days = 1000/250 = 4

Re-order level(R) = dL + z L = 4×15 + 1.64 × 25 = 101

12months sales history – 36 units

12 months sales forecast – 40 units

average sales for 12 months – 3 units

average sales for 6 months – 3.8 units

lead time – 120 days

safety stock – 60 days

replenishment cycle – 120 days

Qty on hand – 22 units

Qty on order – 0 unit

MOQ – 1

What quantity is the recommended order? Thank you.

Need reply by 1pm, Thanks in advance, God bless!

Hey Aldous,

Thanks for reading. Based on the numbers you gave, if you want to have safety stock for 60 days you would need 7.6 units (3.8 units/month x 2 months). If you’re ordering 3 times per year and need to account for safety stock then every 120 days you should order 21 units. This would give you 63 total units over the course of 12 months (40 to account for your forecasted and 21 for safety stock). Hope this helps.

Cheers,

Jared

What are the impact of reorder cycle on inventory cost and stock availability ?

Hey Hilda,

That’s a great question! The reorder cycle can have several impacts on inventory cost and stock availability. For example, longer reorder cycles will result in higher holding costs, and shorter reorder cycles will result in lower holding costs. Ordering costs can also increase if your ordering more frequently (shorter reorder cycle) but if you opt for longer reorder cycles you’ll risk potential stockouts. In regards to stock availability longer reorder cycles make you more susceptible to stock outs, as we mentioned, while short reorder cycles will ensure you’re stock is always replenished. You should also factor that the longer you wait to order more products the more likely you will see an increase in the price (damn inflation). Setting proper reorder points is all about achieving that perfect balance, so you can get the best of both worlds.

I hope this helps!

Cheers,

Jared

This is a fantastic breakdown of the reorder point formula and its importance for inventory management! The explanation of how to calculate average daily sales, lead time, and safety stock makes it easy for any business owner to get started with optimizing their inventory levels.

I especially appreciate the practical examples—like calculating average daily consumption of fuel of our cars and factoring in safety stock for unexpected demand spikes. It’s clear that using the reorder point formula not only prevents stock outs and overstocking but also improves customer satisfaction and reduces unnecessary costs.

Hey shella,

Thanks for reading, and for the kind words.

Cheers,

Jared

I’m a beginner at this and trying to build a reordering system for bulk parts/materials like screws, bolts, etc. But unlike the main product units which have sales and demand data, the bulk parts that are used to assemble the main units do not have this data as they are not planned in the material master data, thus I can only try to figure out the reorder point and quantity based on historical PO data. But it’s been really hard as bulk parts are counted as non-inventory items meaning they aren’t tracked in terms of quantity. This makes the task infinitely more difficult and I am at a loss how to forecast the reorder point, quantity and when to reorder.

Hey Felice,

This sounds like a tricky situation. Since your screws, bolts, and similar bulk parts aren’t tracked as inventory, it’s tough to forecast when to reorder. For this situation, I would recommend you review your historical PO data over a significant period (e.g., 6–12 months), and estimate your average daily usage based on how many you typically order and how often, then pair that with your supplier lead times to estimate a basic reorder point.

That said, the root issue is that these bulk parts aren’t being tracked properly. While it may seem like overkill, you should be tracking screws and bolts as raw materials in your inventory system. Once tracked as raw materials, you can connect their usage directly to how many finished products you’re assembling, giving you clearer visibility and better control over stock levels.

If you’re using a system like inFlow, enabling raw material tracking and linking those parts to an assemblies bill of materials (BOM) will help automate a lot of this process going forward.

I hope this helps,

Jared

Very detailed calculator. Will you integrate supplier pricing for more accurate cost estimates?

Hey Build n Beam,

Thanks for reading. To answer your question inFlow already integrates supplier pricing for more accurate cost estimates! I hope this helps.

Cheers,

Jared

This guide simplifies the reorder point and safety stock calculations, making inventory management more approachable. The practical examples and clear formulas are especially helpful for small businesses aiming to optimize stock levels.

Thanks for reading!