While excess stock can accumulate for various reasons, such as inaccurate projections of customer demands and over-purchasing, it is, unfortunately, becoming an increasingly significant issue. Companies that continually have an overabundance of stock are responsible for substantial amounts of waste. This waste can negatively impact the business itself and the environment. Recent reports have shown that most waste and carbon emissions today come from businesses, especially large companies and corporations.

Not only does the stock itself go to waste, but excess inventory can also result in waste from transporting the stock, packaging waste, and waste from having to keep all of the excess inventory stored. Of course, safety stock — which is simply extra stock kept on hand to avoid stockouts — can benefit companies by helping them stay on top of consumer demands. But too much safety stock can do more harm than good.

Recently, in response to the pandemic, companies have started to keep more stock on hand to avoid disastrous stockout issues. However, while it is understandable for a business to have some safety stock, keeping too much is not sustainable long-term. There are some positive aspects of holding on to excess inventory, but over time this can also cost a company a significant amount of money, not to mention the negative impact it can have on the environment.

Excess stock wastes more than money

Safety stock can provide companies with a buffer if there are issues with supply or an increase in customer demand. The negative implications of too much safety stock tend to outweigh the positives. Overall, when a business continually has too much inventory, it can harm its profitability. Inventory that sits on the shelf unused loses value over time and can eventually result in a loss of revenue. Furthermore, not only do companies risk wasting their money by over-purchasing stock, but they also lose money having to keep all of that excess inventory stored.

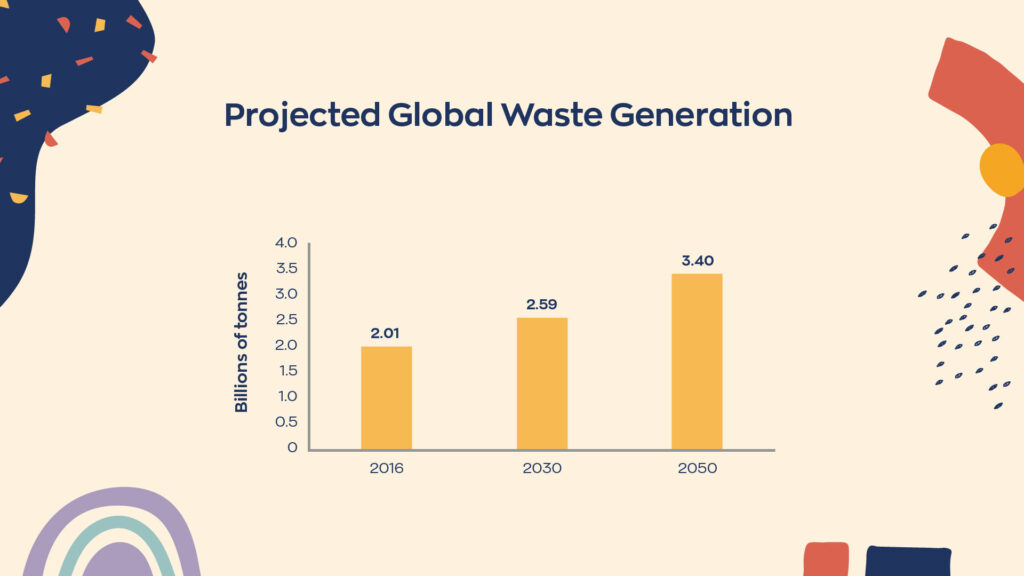

Of course, excess stock is not just a money issue, but it is also a waste issue. All of the products companies manufacture, purchase, store, and sell result in overconsumption of resources and excess waste production, which is disastrous for the environment.

Energy waste

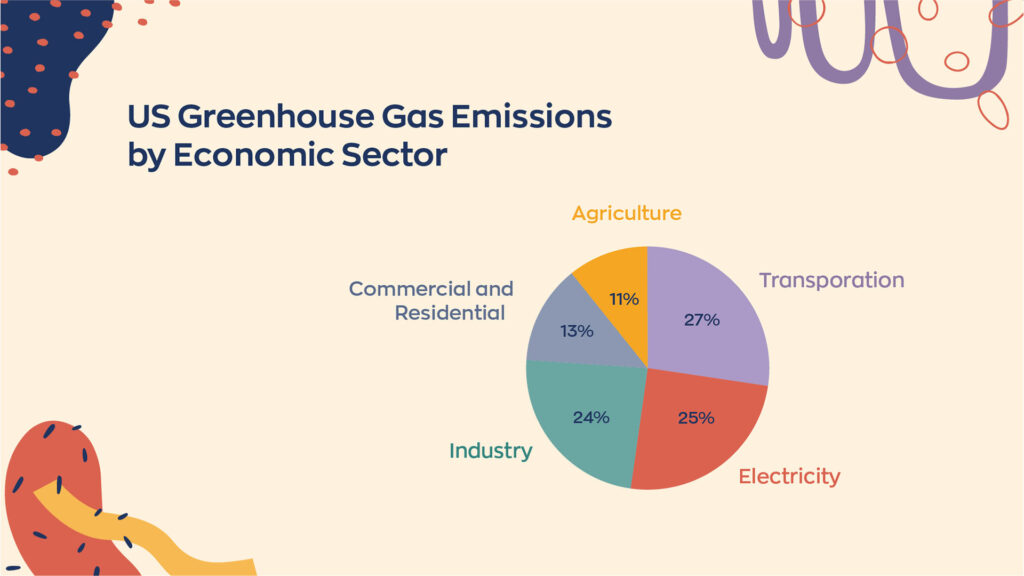

Nearly every part of the supply chain consumes energy. The more energy that is consumed, the more fossil fuels are burned, releasing toxic emissions into the atmosphere. Though reports have shown that just 100 companies are responsible for over 70% of greenhouse gas emissions, all businesses, no matter their size, consume significant amounts of energy compared to individuals and households.

This is because it takes energy to manufacture the products, transport them, keep them stored, and ship them to customers. The transportation industry alone — which is how products are moved from manufacturing plants to warehouses, stores, and customers — is responsible for 27% of U.S. carbon emissions.

Product waste

Pollution from excess waste produced by companies is also a major issue. The products that go to waste and that are not disposed of properly can contribute to food waste, e-waste, clothing waste, and plastic waste. Products that end up in landfills or natural environments also break down over time. This process can emit other harmful gasses and chemicals into the atmosphere, the ground, and the water supply.

Plastic waste, in particular, is one of the biggest issues our planet is facing. This is because so many of the products we buy are made and packaged using plastic materials. In 2018, the U.S. alone was responsible for 35.7 million tons of plastic generation, the majority of which ends up polluting landfills and natural environments. So, the more excess inventory companies purchase, the more waste they produce or contribute to.

Analyze safety stock to optimize inventory

When it comes to inventory, the key is to find the right balance. Too much, and you risk losing money, wasting products, and increasing your carbon footprint. Too little, and you risk running into stockout issues and not being able to keep up with customer demands. The goal should be to get as organized as possible and optimize your inventory to meet demands, reduce carrying costs, avoid stockouts or overstocking, and achieve sustainability.

Demand plan

Demand planning or forecasting is a key strategy in helping companies control their inventory. It involves the use of analytics to review historical data and make predictions or estimates for future demands on products. By looking at how products have moved in the past, companies can get a better understanding of the market and make more informed supply decisions to avoid under- and over-purchasing stock.

Calculate turnover ratio

Inventory turnover is simply the rate at which a company must replace its inventory based on the sales in a given period. For example, a high turnover rate means you sell products quickly. A low turnover rate means sales are down and there is too much stock. Understanding turnover ratio and how to calculate it can help companies better manage their inventory and make better stock purchasing decisions.

Evaluate current stock

Knowing how much stock to buy relies heavily on companies having an accurate count of their current stock levels. Despite systems improving over the years, businesses still run into issues with inaccurate inventory and stock counts in their warehouses. This is most often due to human error. So it’s essential to use the latest tools and systems, such as wholesale software or warehouse management software solutions. These ensure you have a thorough evaluation and count of inventory levels at all times.

When evaluating your stock, it’s also helpful to understand the difference between stock and inventory. Your stock consists of products that are finished and ready to go. Whereas your inventory can include products that are a work in progress and unfinished in addition to ready-to-go stock items. Distinguishing between the two can help your company stay better organized and ensure you only order the right amount of stock when needed.

Explore other options

Other options for managing excess inventory and safety stock to be more efficient and sustainable can include:

- Finding ways to recycle and repurpose overstock

- Working out a consignment deal for over-purchased clothing stock

- Installing energy-efficient upgrades to warehouses and storage areas

- Cleaning out overstock on a cycle

- Using storage spaces for other, more efficient purposes

Making sure that you’re not keeping too much stock in your inventory is beneficial for both your business and the environment. Stay clear of these sustainability issues surrounding safety stock, and reap the rewards of ethical warehousing.

0 Comments