Something that business owners learn very quickly is the importance of time. Not only is it a highly limited resource, but it’s also required to get anything done, making it a valuable currency. It’s the main reason businesses are always looking for ways to increase efficiency. Naturally, this carries over to the manufacturing side of things as well. Lean manufacturing is a product of this ideology. So: what is lean manufacturing? How does it relate to the Toyota Production System (TPS)? And how does it reduce waste for manufacturers?

For the TLDR on lean manufacturing watch this short clip from our new podcast!

How does TPS relate to lean manufacturing?

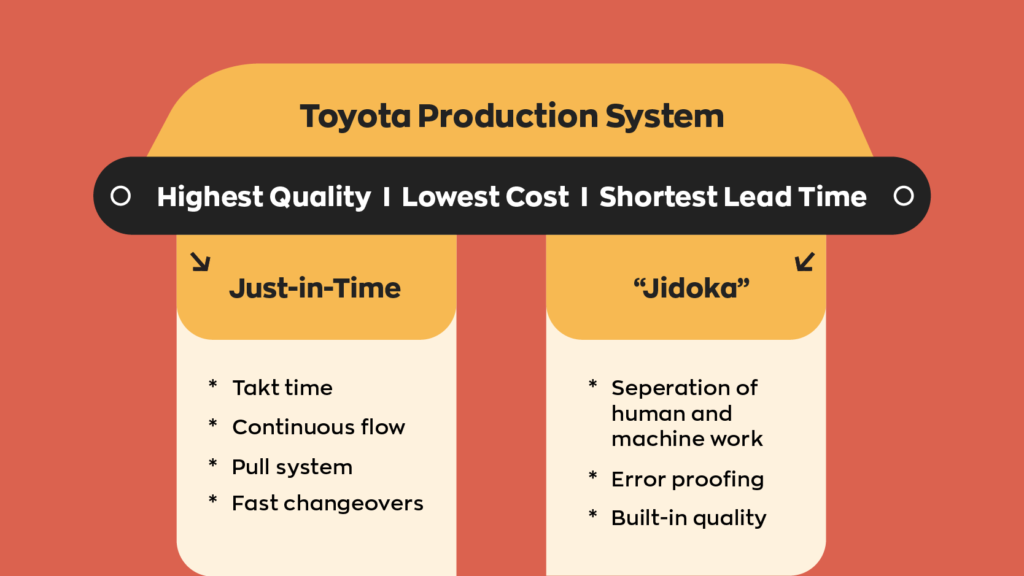

In order to understand lean manufacturing, it’s necessary to have an understanding of the TPS or Toyota Production System. First coming into prominence in the 1950s, the TPS functions based on two core “pillars.”

Just-in-time (JIT) is the principle that each process only produces what the following process needs. It also minimizes the amount on hand, increasing cash flow.

Jidoka is a Japanese term that’s a bit more complex. It roughly translates to “automation with a human touch.” To keep things simple, this means that when an error occurs, the manufacturing process stops, which prevents defective products.

It’s important to note that TPS is a principle, while lean manufacturing is a production system. The two are not the same thing.

What is lean manufacturing?

The definition reads something like this: “lean manufacturing is a process that aims to maximize productivity and minimize waste.” Pretty non-descript, right?

That’s because there’s no real answer to this. The process differs from industry to industry, but the ideas stay the same. Lean manufacturing is a process that aims to maximize productivity while minimizing waste through 5 principles.

- Identify value: This principle asks businesses to understand what value their products provide to their customer. This can reduce costs by cutting out unnecessary product features.

- Chart the value stream: A value stream is a construct that shows how a product creates value. By extension, it also indicates what steps you must take to add value to those products.

- Flow: As much as we’d like to take credit for this term, we can’t. Still, there’s no better way to describe it. Maintaining flow (ha!) means moving products and components through processes as efficiently as possible. This reduces idle time and helps eliminate bottlenecks and/or blockages.

- Establish a pull system: Remember that pull systems aren’t exclusive to lean manufacturing. We’ll be talking more about pull systems next week, but for now, a pull system manufactures products according to demand. When an order comes in, a new work order is put in. This increases cash flow and minimizes capital tied up in work-in-progress inventory and stored finished products.

- Perfection: Just to be clear, perfection is an impossibility. Human error is a constant, and even if it weren’t, machines malfunction. Still, though, perfection– or as close to it as you can get– is an essential part of lean manufacturing. Lowering the margin of error reduces defective units, saving money.

How does lean manufacturing reduce waste?

The lean manufacturing system aims to reduce 7 types of waste by minimizing downtime and making processes more efficient.

Unnecessary transportation: When a component or product is in transit, it’s not actively contributing to the manufacturing process.

Excess inventory: In terms of manufacturing, this means raw materials or work-in-progress (WIP) inventory. Lean manufacturing decreases the amount of inventory on hand, which frees up capital to use elsewhere.

Unnecessary movement of people or equipment: Similar to unnecessary transportation, when an employee or equipment is in transit, they’re not actively contributing to the manufacturing process.

Idle time: Because different parts of the manufacturing process rely on each other, the production flow can halt because of a single bottleneck.

Over-production: One of the risks of manufacturing in bulk is the fluctuation of demand. If you manufacture a batch and demand drops, you’re left with a hard-to-sell product.

Over-engineering: It’s not uncommon for products to have unnecessary features. Cutting these features reduces manufacturing costs and time, saving money in multiple areas.

Defects: Arguably, the most costly form of waste are defects. If a product is defective, not only does it need to be discarded, it needs to be replaced. This doubles the cost of producing a single unit, meaning that reducing defects can save a lot of long- and short-term capital.

Lean manufacturing seeks to minimize waste output by streamlining the process. Even if the gains seem small– a couple minutes or dollars here or there– targeting so many different parts of the process means that the saved time and money adds up quickly.

Benefits and downsides

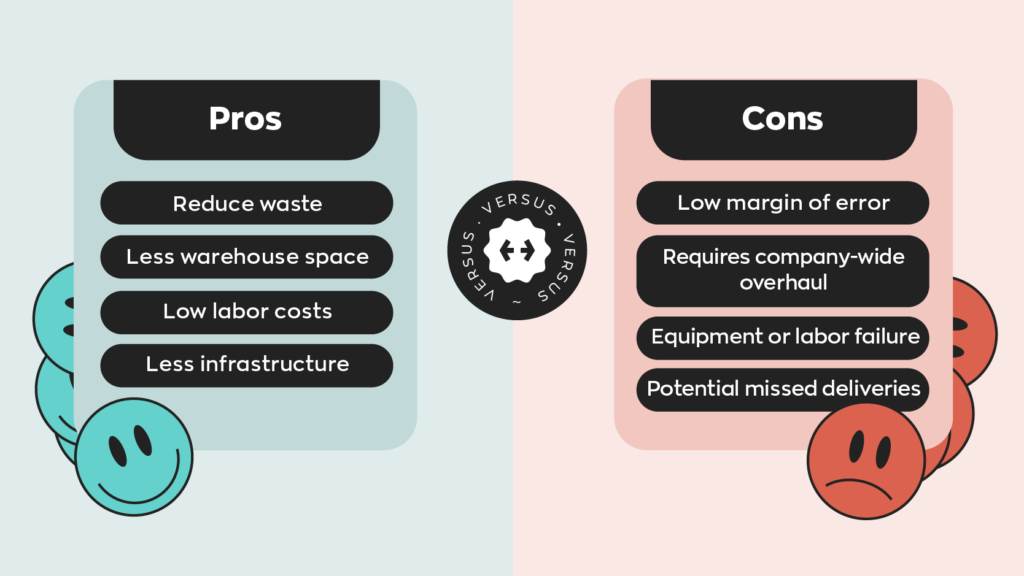

Like many business systems, lean manufacturing saves businesses time and money– and, in the long run, quite a bit of it. This is because it targets many different parts of the process. On top of making the workflow more efficient and minimizing waste, it also reduces inventory kept on hand.

The amount of time and money saved might seem incremental, but because it affects so many different parts of the process, that little amount becomes a lot. It also adds up over time. Over the years, 50 cents saved per unit could add up to tens or even hundreds of thousands of dollars saved.

The biggest downside of lean manufacturing comes from its use of a pull system and its relation to JIT inventory. This leaves very little room for error. Being one component short could leave the product unfinished, creating further bottlenecks down the line.

Lean manufacturing also isn’t something that you can implement right away. Noticing and eliminating inefficiencies requires a lot of information over a significant period. It could take months, or even years, to gather the necessary data.

Where to start?

Like so many other things in the business world, decision-making depends on information above all else. This means you need near-total control and insight over both the manufacturing process and inventory management. Finding a system that ties together inventory management and the manufacturing process goes a long way in making it more manageable.

inFlow offers a perpetual inventory management system and comprehensive manufacturing software, keeping everything in one place.

0 Comments