In the 21st century, businesses don’t need to be brick-and-mortar. In fact, many successful businesses are run through e-commerce websites that provide goods and services for customers around the world.

If you run an e-commerce business, it’s important to manage your inventory in a way that’s best for your business and customers. For every entrepreneur, managing inventory looks different. For example, some use barcode scanners, others use a spreadsheet. Some do physical inventory counts, while others do cycle counts. For this reason, what matters is that you use the tools and techniques that work best for your unique business.

Using optimized inventory management software can help reduce delays, streamline record-keeping, and improve customer service.

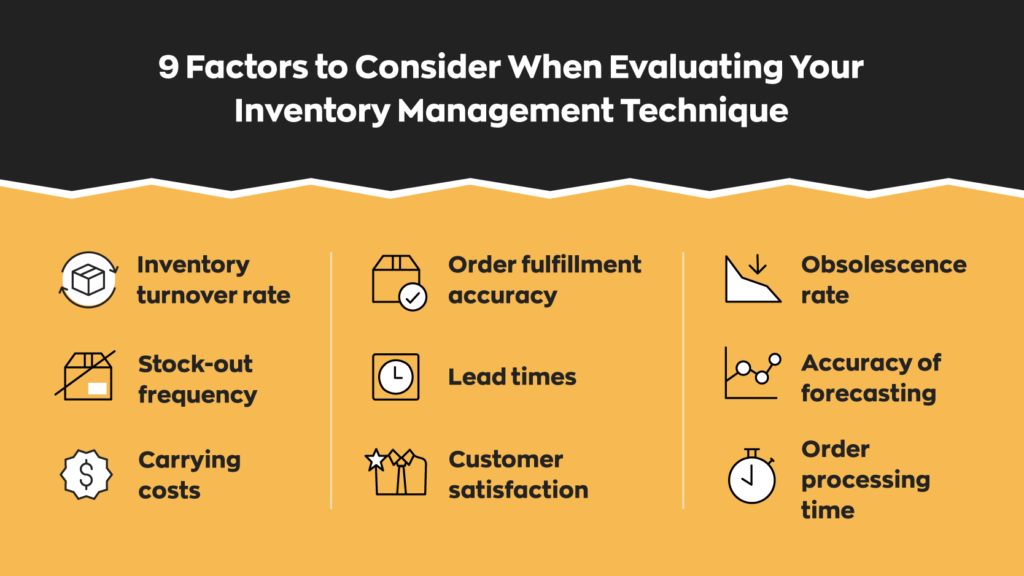

Reevaluate your inventory management technique

There are a variety of inventory management techniques a business can use. Each technique offers different advantages and disadvantages for the business owner. For example, third-party logistics (3PL) fulfillment allows you to outsource large portions of the order fulfillment process. While the just-in-time (JIT) system allows you to minimize waste and cash flow problems.

Evaluating your current technique can help you identify new ways to optimize your ecommerce website’s inventory management system.

JIT

Just-in-time (JIT) inventory management has been popular for decades. However, in the last few years of supply chain issues, many people are reevaluating using JIT.

For JIT inventory management, a company orders only what they need in the immediate future. Meaning you only order from manufacturers when customers buy products from your website. Obviously, this reduces the costs of storing goods and parts, reduces waste, and minimizes cash flow issues.

However, JIT may also lead to higher delivery costs and problems due to supplier delays. Weighing the pros and cons of this inventory management technique can help you to decide whether it is the best option for your ecommerce website.

FIFO

With a first-in, first-out (FIFO) inventory management strategy, you send out the inventory you’ve had in stock the longest. The inventory you buy first is sold to customers first.

This method helps businesses keep track of the value of the goods in stock. FIFO ensures that, due to inflation and market changes, your inventory at the end of the fiscal year is worth as much as possible. This improves your chances of higher tax write-offs and savings.

FIFO is particularly helpful if you sell perishable goods. This method allows you to easily calculate the ultimate inventory value while simultaneously managing your inventory of perishable goods.

Dropshipping

Dropshipping has been a popular buzzword on the internet in the past decade. This inventory management model allows entrepreneurs to run ecommerce businesses entirely from their computers. There is no need for any storage facility or shipping responsibilities.

If you use the dropshipping inventory management system, you actually don’t manage your inventory at all. When a customer orders a product from your store, you place an order with a vendor who gathers the ordered products and ships them to your customer.

With a dropshipping business, your job is to bring in customers and place orders. Beyond that, all inventory and shipping are handled by your chosen vendor.

3PL fulfillment

Third-party logistics (3PL) fulfillment inventory management takes advantage of the services of a 3PL company to handle many aspects of inventory management. In particular, this includes storage, order fulfillment, and even returns.

Many 3PL companies will receive your inventory to store at their fulfillment center. To ship orders to customers, some 3PL companies require you to manually enter the order into their system, while others offer options that integrate your online store with the 3PL company’s shipments.

3PL fulfillment centers can handle everything from inventory storage to packing to shipping. You will need to assess your budget and determine whether paying for third-party logistics is worth the cost.

Implement a barcode scanning system

As you work to optimize your inventory for your e-commerce business, it’s important to reduce human error as much as possible. One way to do this is to implement a barcode scanning system.

Using a barcode scanner and software that connects codes with specific product information, you can track your inventory easily and with reduced errors. Each product will have a specific barcode, and scanning these codes as products are sold will keep your digital records up to date.

Many small businesses use free or low-cost resources like Google Sheets or Microsoft Excel to track inventory, but using a barcode system can simplify your system, reduce errors, and save time.

Audit your supply chain

When optimizing your inventory, it’s important to look at every part of your business and how you’re delivering goods to your customers. Auditing your supply chain involves looking at each individual step for how you deliver goods and finding places where problems are occurring.

Identifying parts of your supply chain that need to be changed and optimized can help you limit future risks. For example, if your supplier is having regular delays and causing you to send out deliveries to clients at a slower rate, that can cause reputation problems. In other words, customers won’t see you as a punctual and reliable business.

Changing your supplier, shipping company, and even your personal inventory management strategy can help optimize the supply chain and provide a better experience for your customers.

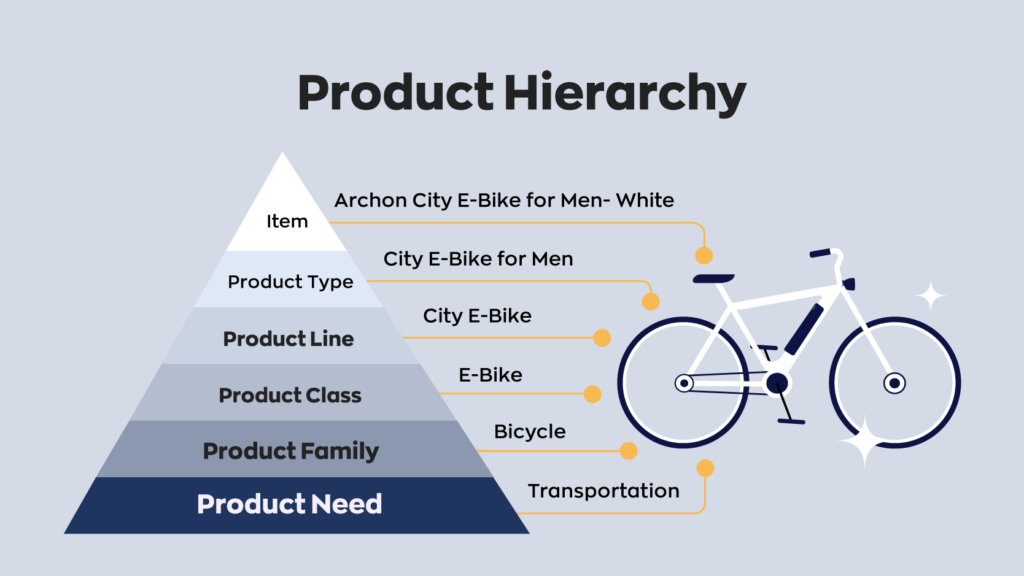

Create a product hierarchy

A product hierarchy is a model that allows you to look at your business as a whole and see how your products and services fit together.

A product hierarchy can help you to understand the different price points that exist within your business and how certain products are connected to future purchases. In addition, your product hierarchy can also help you to identify which pricing strategy is best for your business.

If you are a wholesaler, creating a product hierarchy and deciding on a pricing strategy is important. Using a wholesale inventory software system can help you to change product prices with minimal stress as needed.

Perform cycle counts

If you have a large supply of inventory, conducting a physical count of your inventory and counting everything at once can be daunting. However, performing cycle counts is a worthwhile alternative that can save you time and energy.

Inventory cycle counting involves counting specific categories of inventory in a repeating cycle. For example, if you sell a wide variety of clothing, you may count all of your shirts one week, pants another week, and shoes the third week. Once you’ve counted each category, you start at the beginning again.

Cycle counts are less disruptive to your regular business activities because they require much less time and staffing than a count of your entire inventory.

Monitor your PAR levels

Periodic automatic replacement (PAR) is a warehouse management system that helps your business maintain the correct amount of inventory to fulfill current orders. The PAR level for your inventory can change based on the time of year, holidays, and other factors.

To maximize the benefit of periodic automatic replacement, you will need to look at historical sales data to determine the minimum and maximum amounts needed at all times for each type of product you sell. For example, if you sell organic dog treats, your minimum will be the amount you want to keep in stock to keep up with demand, and your maximum will be the amount you can keep without leading to excessive inventory waste.

If you work with perishable goods, then monitoring your PAR levels is important to maintain the correct amount of inventory to eliminate waste or shortages.

By re-evaluating your inventory management technique and using the systems and software available to e-commerce businesses, you can optimize your inventory, reduce waste, and create a top-notch buying experience for your customers.

0 Comments