Key takeaways

- Common causes of human error in the workplace are unclear processes, distractions, fatigue, and poor training, particularly in fast-paced environments like warehouses.

- Implementing standardized procedures and visual aids such as labels, checklists, and floor markings, can greatly reduce confusion and prevent mistakes.

- Automation tools such as barcode systems and inventory management software significantly lower the risks that come along with manual data entry.

- Regular training and refresher courses help reinforce correct workflows and keep employees updated on system or process changes.

- Creating a safe workplace culture that encourages reporting mistakes without fear of punishment leads to continuous improvement and fewer repeat errors.

Human error affects every workplace, from small offices to large manufacturing facilities. It can lead to lost productivity, wasted resources, and accidents or injuries. However, there are several steps that businesses can take to reduce their error risk, improving the efficiency of their operations and protecting their employees. Here are ten ways to do just that.

Set reasonable goals and deadlines

Setting goals and deadlines is essential for any business to stay competitive and grow. However, setting unreasonable goals and deadlines can harm employee morale and mental health and increase the likelihood of human error. Moreover, when businesses set deadlines that are too tight or goals that are too lofty, they end up piling too much work on employees. This often leads to burnout, leading employees to become unproductive, anxious, and unenthused, increasing the risk of errors.

To ensure that goals and deadlines are reasonable, businesses should solicit employee feedback about what is achievable. This will help to ensure that expectations match reality and reduce errors. Beyond this, there are several other ways to set reasonable goals, such as:

- Setting short-term goals that are easier to reach and gradually increasing the difficulty level.

- Allocating resources (e.g., people, money) in line with what is needed for each goal/deadline.

- Allow for flexibility. Being too rigid in processes and procedures can cause frustration among employees. This can lead to mistakes when employees try to complete tasks within a limited framework.

With incremental process changes, businesses help employees define and manage work.

Automate tasks when you can

Automating tasks saves money, reduces errors, and boosts efficiency for businesses. Sustainable automation through tools and strategies can future-proof and accelerate growth by minimizing resource waste and maximizing productivity. It also enables employees to focus on higher-level problem-solving and strategic initiatives.

For example, implementing a customer relationship management (CRM) system to improve customer service or utilizing analytics software to identify trends and opportunities in data.

Increase oversight

Increasing oversight within businesses can lead to better performance, fewer mistakes, and improved employee accountability. Of course, every company is different, but here are a few ways to implement this:

- Mandating procedural training: Procedural training familiarizes employees with company policies, processes, and best practices, promoting consistent performance and reducing errors.

- Adding more managerial staff to each shift/department: This allows managers to monitor performance, provide guidance, and address issues promptly.

- Utilizing technology: Tech tools enable businesses to monitor employee activities and improve productivity through time-tracking software, project management tools, and communication platforms.

- Establishing performance metrics and goals: Establishing key performance indicators, conducting regular evaluations, and supporting improvement for underperformance promotes a results-driven work environment and employee growth.

- Implementing an open-door policy: Encouraging open communication between employees and management fosters transparency, accountability, and early problem identification, creating a supportive work culture.

Depending on your business’s needs and operations, there may be additional steps you can take.

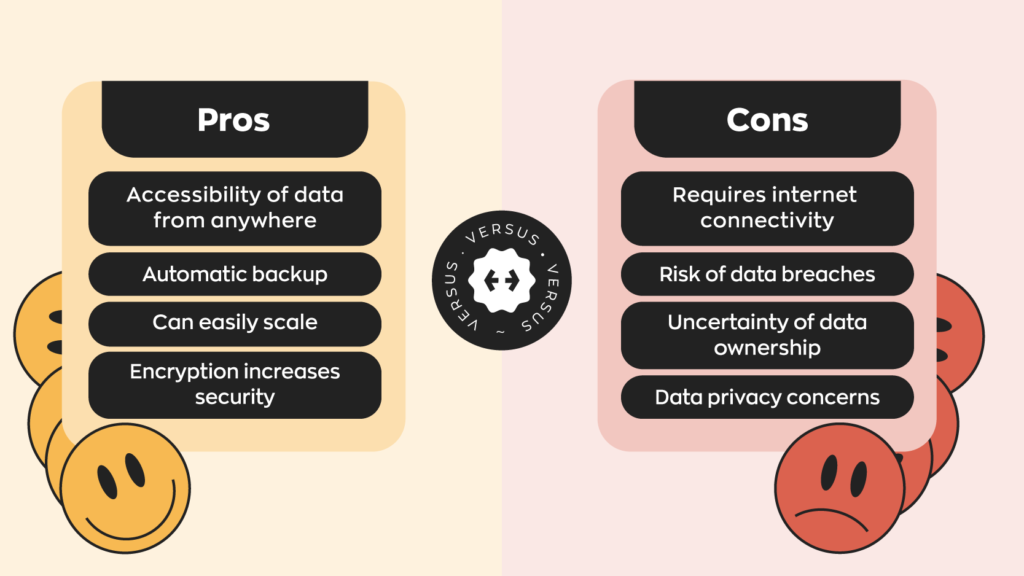

Back up documents in the cloud

Backing up critical documents in the cloud is crucial for businesses and individuals. Traditional storage methods, such as physical files or local hard drives, are susceptible to loss, damage, and accidental deletion. By utilizing cloud storage, users can ensure that their valuable data is securely stored in a remote location, with multiple copies maintained for redundancy. For an added layer of protection, you should also choose reliable antivirus software to safeguard against potential cyber threats and malware attacks.

In addition, cloud-based data backups also improve accessibility for employees. With cloud storage, team members can access important documents from any device with an internet connection, facilitating collaboration and enhancing productivity. This capability allows employees to work remotely or across multiple locations without physical document transfers or time-consuming file searches.

Reducing human error in manufacturing

Manufacturing facilities face unique challenges when it comes to reducing human error and managing risks. Unlike office environments or retail settings, manufacturing operations often involve complex machinery, high-speed production lines, and hazardous materials. Consequently, the stakes are considerably higher, as errors in this context can result in costly downtime, compromised product quality, or severe employee injuries.

Prioritize compliance training

Regular compliance training is critical for reducing risk and preventing accidents in warehouses. The fast-paced and ever-changing nature of warehouse operations can create significant risks. Compliance training keeps employees informed and educated on regulations, procedures, and safety protocols for secure and efficient warehouse operations.

Training can also help employees understand the potential consequences of failing to follow these guidelines, including financial penalties, legal action, and reputational damage.

Moreover, compliance training can help prevent damaging accidents by promoting a safety culture in the warehouse. Regular training sessions can reinforce safety protocols and procedures and provide updated information on changes to regulations and best practices.

Improve communication

With multiple tasks, employees, and machinery, clear and efficient communication is crucial. It reduces the risk of misunderstandings, misinterpretations, and mistakes, which can have serious consequences in warehouse settings.

Implementing a new warehouse management system can be an effective way to improve communication in a warehouse. Such a system can provide real-time inventory, equipment, and personnel data, allowing managers to track operations and make informed decisions. Additionally, automated systems can send alerts and push notifications to employees, reducing the likelihood of errors that result from miscommunication.

Other ways to promote effective communication in the warehouse include:

- Holding regular meetings.

- Developing a clear chain of command.

- Creating guidelines for reporting errors and incidents.

Publish and post work procedures

When employers communicate procedures clearly to all employees and make them easily accessible, the likelihood of correct and efficient operations increases. One approach is to use posters and signs in strategic locations throughout the warehouse, particularly near each operation or process.

Using images and symbols in warehouse signage can significantly improve safety and efficiency by effectively communicating information, particularly to employees with different levels of literacy or language skills.

A few examples of effective signage include:

- Step-by-step instructions for operating equipment.

- Cautions and warnings about hazardous materials and processes.

- Notifications about safety protocols and regulations.

- Reminders on how to lift heavy objects safely.

- Posters that describe the consequences of failing to follow procedures or regulations.

These types of precautions ensure a smooth and safe operation.

Reducing human error in warehouses

Warehouses have unique considerations for error reduction and risk management due to their fast-paced and complex nature. Preventing these errors requires targeted strategies that address the specific challenges of warehouse operations.

Reassess your storage practices frequently

Reassessing storage practices is a critical aspect. Regularly evaluating the layout and organization of the warehouse can identify potential issues and opportunities for improvement. When conducting these assessments, several factors should be considered, including:

- Clear labeling: All items within the warehouse, including shelves, bins, and individual items, must have clear labeling. The labeling style needs to be consistent throughout the entire warehouse and utilize fonts that are easy to read.

- Accessibility: Items must be easily accessible for all personnel, including those with disabilities.

- Demand: Higher-demand items should be placed in more accessible locations, reducing the need for employees to search for them and minimizing the potential for errors.

- Safety: Heavy items should be stored at ground level or on lower shelves to reduce the risk of employee injury. Additionally, flammable or hazardous materials should be stored in a separate, secure area, away from other inventory.

Beyond this, regularly tracking inventory levels with a management system ensures accuracy and minimizes errors.

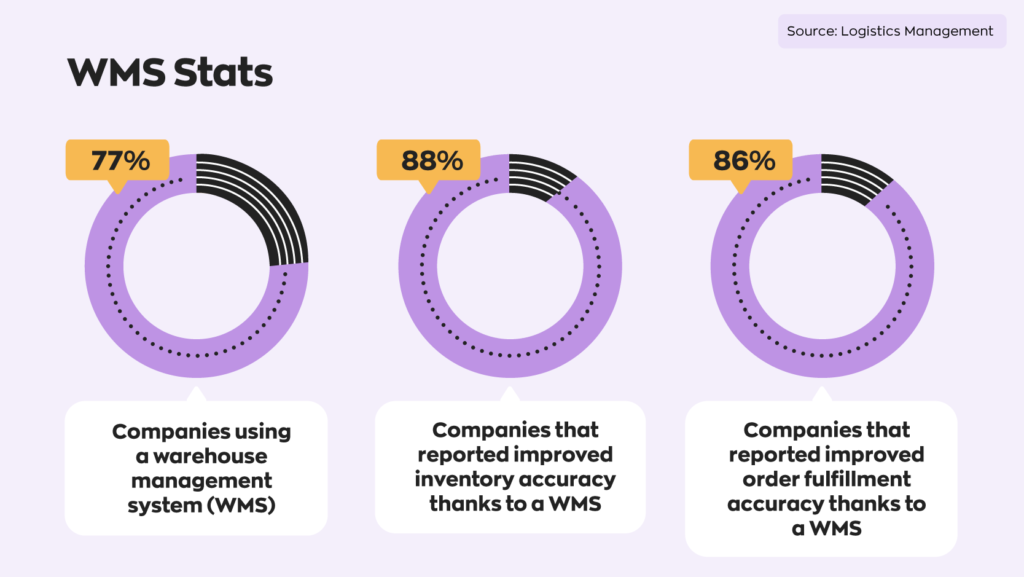

Utilize a warehouse management system

A warehouse management system (WMS) is a software application that helps manage and track warehouse inventory, orders, and shipments. WMS software can automate many tasks previously done manually, such as tracking inventory levels and locations, managing order fulfillment, and providing real-time data on warehouse operations.

With a WMS, warehouses can prevent human error by reducing reliance on manual labor and improving accuracy. For example, the software can provide real-time data on inventory levels, preventing errors that may result from stockouts or overstocks. Additionally, WMS software can automatically generate pick lists, reducing the need for manual data entry and minimizing the potential for errors.

Implement a barcode scanning system

Implementing a barcode scanning system is an effective way to reduce errors and keep better track of inventory in warehouses. Barcode scanning systems use barcodes to track items and provide real-time data on their location and status. Barcode labels can be applied to shelves, inventory, and assets, making scanning and monitoring them throughout the warehouse easy. Additionally, barcoding inventory and assets can help warehouses keep track of their items, making locating and managing their movement easier.

While it may seem challenging to implement such a tedious system, any warehouse can make it happen with the right resources and guidance.

By combining technology and effective management practices, any business can create a safer and more efficient work environment while minimizing the potential for costly mistakes.

need information

Hey Anas,

Could you be more specific. I would love to help if I can.

Cheers,

Jared

You clearly know what you’re talking about. I enjoyed reading this.

Hey Trista,

Thanks for stopping by 🙂 We try our best to provide our readers with valuable, actionable insights. If you like our content please consider subscribing to our newsletter at the bottom of this page to stay up to date with all our new content.

Cheers,

Jared

I like the way you explained the concept here. Very clear and informative.

Hey Regina,

Thanks so much! We aim to make things as easy to understand as we can. Glad you enjoyed it 🙂

Cheers,

Jared