Running a manufacturing business is, well, tricky business. There’s also no real guide or “how-to” on how to run one. There’s a handful of reasons for this, but the most obvious one is simply that every business has different needs. At the same time, though, the tools that manufacturers use don’t differ too much from business to business. One of these tools is the bill of materials (BOM). So: what is a bill of materials? And how do manufacturers use them to keep track of things? Let’s dive in!

What is a bill of materials?

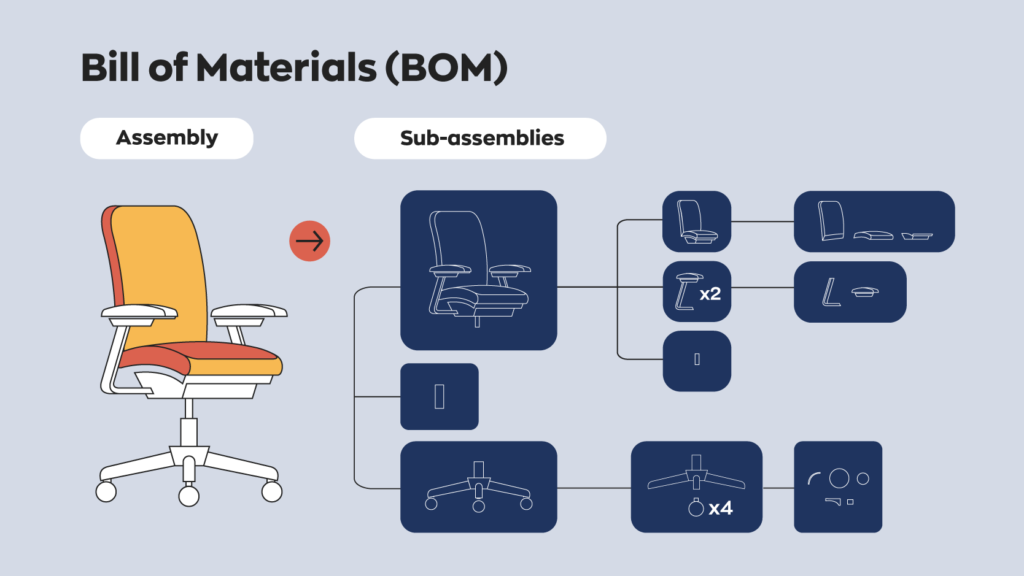

A bill of materials is a reference list that manufacturers use to streamline and track their manufacturing process(es). That sounds complicated– and it can be– so it helps to break things down. It’s important to note that there are a lot of different manufacturing processes out there. As a result, there are also a lot of different types of BOMs. More on that later.

Even in the same industry– and for the same product– things might differ from business to business. At the same time, though, there are almost always a few data points that remain consistent. BOMs typically contain the number of raw materials needed, the cost of those materials, as well as the general procedure.

Single-level vs. multi-level bill of materials

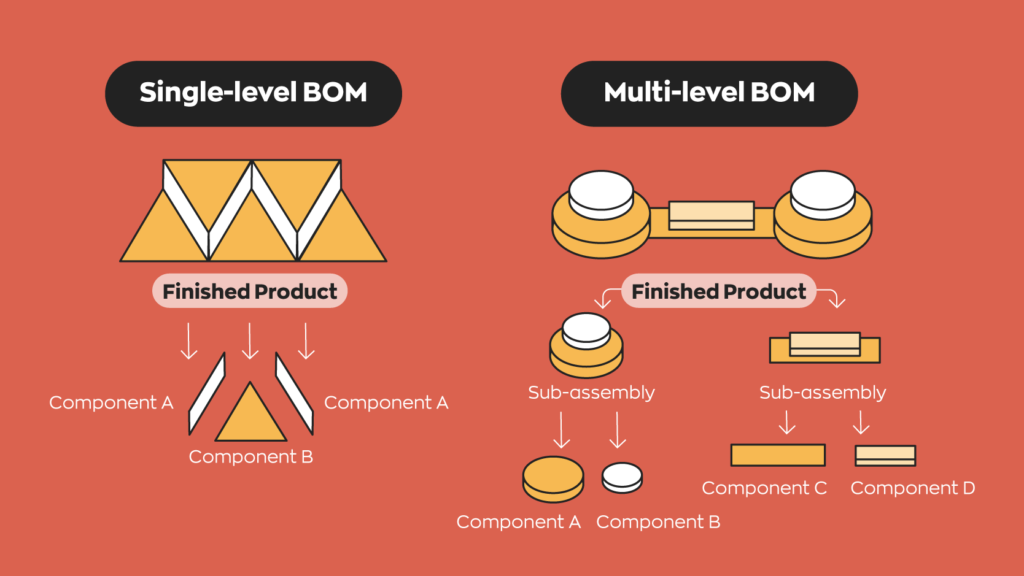

Despite the many different types of BOMs out there, they all fall into one of two categories: single or multi-level. Which category they belong to depends on whether or not the bill of materials includes assemblies only or sub-assemblies as well.

- Assemblies are the components that are used to build the end product directly. For example, building a modern computer requires more than one manufacturing round. The components are built in separate places, and then all put together somewhere else.

- Sub-assemblies are the components used to build the components of the end product. For example, a central processing unit (CPU) is part of a modern computer but requires its own assembly process.

In this example, the CPU itself is part of the assembly, and the components used to make the CPU are part of the sub-assembly.

Single-level BOMs only contain assemblies, while multi-level BOMs contain both assemblies and sub-assemblies. Sub-assemblies are placed on different “levels”, hence the name.

Which BOM should you use?

It’s something we say a lot, but it remains true– every business has different needs. This is especially true when dealing with the manufacturing process, and it’s why using the right bill of materials is important. It’s impossible to tell what businesses need which bill of materials at-a-glance, but there are some general guidelines.

A single-level bill of materials is simple and easy to implement but doesn’t offer much information. At the same time, though, simple is sometimes best. If your assembly process is simple– like, say, building a table– it might be best to use a single-level BOM. It’s simple, gets the job done, and won’t confuse new workers.

A multi-level bill of materials is a bit trickier. It offers more information at a glance but also requires much more information to create and implement. They also tend to be larger and more complicated, which can make them difficult to maintain. Multi-level BOMs are best used for complicated processes that require more precise tracking.

Again, there’s no one size fits all. Some businesses only need basic information, while others need in-depth documentation. Figuring out which one works for you is key to making sure things run smoothly.

Different types of BOMs

Considering the many industries in the world, it’s probably not surprising to hear that there’s a lot of different BOMs. Here are some of the most common types of bill of materials.

- Manufacturing BOMs contain all the parts and assemblies required to build a complete and shippable unit. They also typically include information on how the different components relate to one another. When using a manufacturing BOM, the product is not “complete” until it’s ready for shipping.

- Engineering BOMs are similar to manufacturing BOMs, but with one key difference. Unlike a manufacturing bill of materials, an engineering BOM is “complete” once the unit itself is complete.

- Configurable BOMs are a bit different. Instead of a strict guideline, they’re more of an estimate. They’re meant to be used for products that depend on customer specifications, such as a custom computer build.

- Production BOMs focus more on the process rather than the outcome. They still list the raw materials used but tend to go more in-depth on the manufacturing process itself.

- Assembly BOMs are similar to a production bill of materials but also list the resources used in the process. This includes manpower and equipment.

What are the advantages of using a bill of materials?

Running a business can be rough. Adding a manufacturing process on top of that can make it even rougher. A bill of materials is a tool that manufacturers use to make things easier. Here are a few reasons to implement BOMs into your operation.

Streamline workflow. This is especially relevant when the assembly takes place over multiple departments. Instead of having to check back in with each other, departments can reference the bill of materials to make sure everything’s on track.

Provide a clear outline. A bill of materials tells you exactly what you need and when. This reduces time spent fact-checking and helps ensure that all materials are on-hand before beginning a production cycle.

Easy to restock. A bill of materials tells you what components you have on hand (and how much), making it easy to know when and what to restock.

How do you create a BOM?

Like a lot of other things, a bill of materials used to be created (and maintained) by hand, usually on a spreadsheet of some sort. That’s still possible today, but over time, it becomes impossible to maintain. There are just too many shifting variables to deal with, which makes managing these spreadsheets over time a nightmare. That means more time spent doing menial work and less time doing the things that really matter.

If you’re insistent on doing it the old-school way, though, we’ve created an Excel template for a bill of materials, among six other templates you can download for free.

In today’s digital age, though, there’s plenty of robust– and affordable– software out there. Instead of manually creating, managing, and updating a bill of materials yourself, automate it!

inFlow offers a perpetual inventory management system on top of manufacturing and BOM software, ensuring that production always runs smoothly.

0 Comments