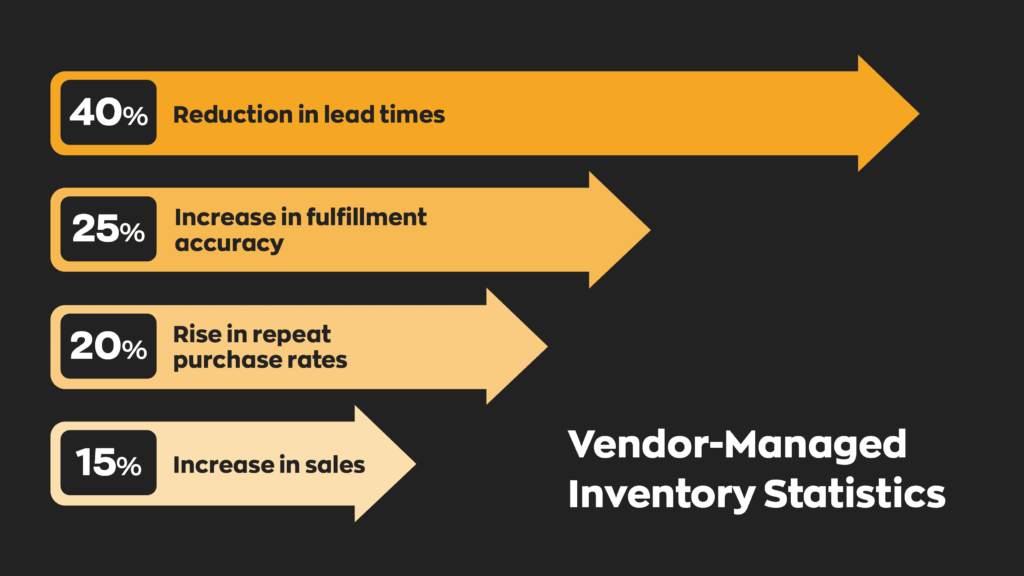

As we move further into 2025, consumers’ expectations continue to rise. One fundamental expectation, in particular, has been a challenge for online stores and traditional retailers alike: lead times. The sooner a customer has their product, the happier they are. This is why many retailers have been exploring vendor-managed inventory, or VMI inventory for short.

Amazon’s two-day shipping on nearly every product for Prime members is a large part of the platform’s continued dominance in the ecommerce market. Matching Amazon’s consumer-aiming policies is a pipe dream for most businesses, but there are still lessons to learn.

Vendor-managed inventory (VMI) takes from one of those lessons. It’s a B2B process that aims to lower lead times by encouraging deeper collaboration between supplier and retailer. But what is VMI inventory? And is it right for your business?

What is vendor-managed inventory?

The textbook VMI meaning is a system in which a vendor manages and maintains inventory for a client. Instead of managing orders and inventory levels, buyers rely on their vendors to ship them products as needed.

The concept itself is simple, but there’s a lot of jargon. It’s also not entirely clear who the “vendor” and “buyer” refers to.

So, let’s break things down a bit.

How does VMI inventory work?

Let’s pretend you own a business supplying products to dental offices. There are various product types, all of which sell at different frequencies. You’ll need to carefully track the sales data for each product type to ensure you maintain optimal inventory levels. The last thing you want is to encounter a stockout or be stuck with excess inventory.

A vendor-managed inventory system makes a lot of sense in a case like this. The supplier will ship products on their own accord, usually based on data your business shares. They decide when to ship more products and how large each shipment is. It offloads some of the responsibility to the vendor and saves you time. In this case, your supplier is the “vendor,” and you, the retailer, are the “buyer.”

Vendor-managed inventory aims to reduce costs across the entire supply chain. Ideally, you’ll also save on warehouse space and shipping costs. Optimizing the supply chain also increases availability and can reduce lead times.

Challenges of vendor-managed inventory

Even compared to similar systems, using vendor-managed inventory incurs unique challenges. Some are simple and easy to resolve, but others can be difficult to deal with. Choosing business partners wisely is always important, but it’s arguably even more critical for VMI inventory. After all, you’re surrendering a lot of control to your suppliers, so you better make sure you can trust them. Here are some challenges you may face when implementing vendor-managed inventory.

Data sharing

In vendor management inventory, the vendor is responsible for providing relevant amounts of product when needed. This process necessitates some level of data sharing, which allows vendors to find the correct reorder points for each product. However, sharing data without outside organizations is always risky, so choosing a reputable partner is crucial.

Another way to mitigate the risk of sharing data with vendors would be using the right inventory management software (more on this later).

Frequent, transparent communication

Vendor-managed inventory requires quite a bit of back-and-forth. More than that, it requires both parties to be honest with each other. Supply issue? Can’t afford the order size? Inform the other party immediately. The nature of VMI inventory also requires coordination between both parties, which warrants more communication anyway.

Culture clash

Sometimes, two groups of people just don’t get along. There’s nothing wrong with that, but it’s difficult to overlook when considering the trust involved in a VMI system. Core values must align for a relationship to be long-lasting. Otherwise, you risk a potential future fallout with a key supplier.

Solving vendor-managed inventory challenges

There’s a few ways you can solve these problems. Remember, though, that vendor-managed inventory isn’t for everyone. Some businesses require complete control over their inventory, meaning VMI inventory isn’t a good fit. However, if you are considering implementing vendor-managed inventory, here are some ways to solve common issues you may encounter.

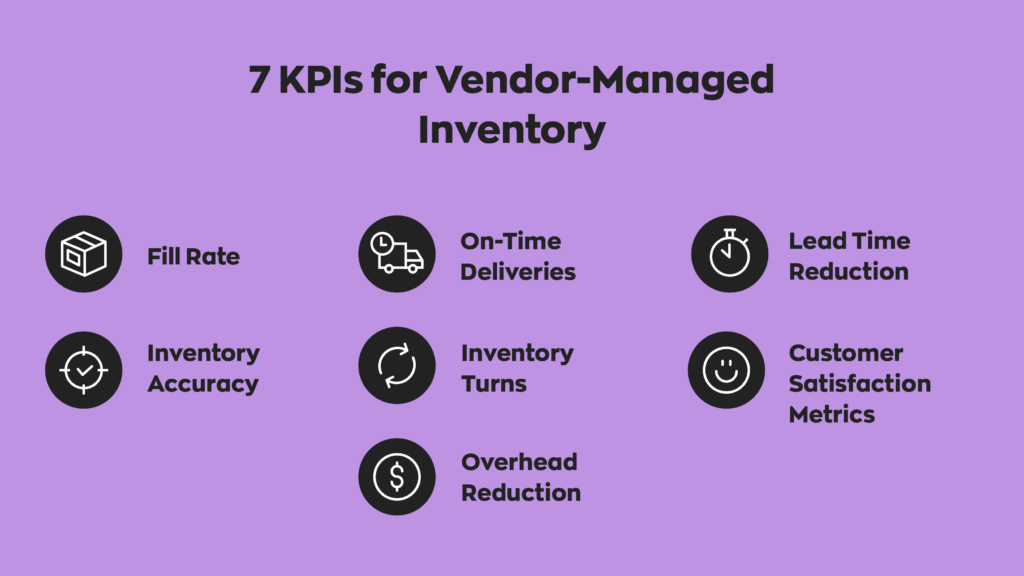

Align key performance indicators

Key performance indicators, or KPIs, are crucial when considering a restock. With two parties involved, it’s essential to ensure that performance goals align. If one party is off track or has a different goal in mind, things tend to get messed up. Tackling this ahead of time will save a lot of pain later down the line.

Use a cloud-based inventory management system

Cloud systems are the easiest way to create a shared ledger. Our perpetual inventory control system, inFlow, records changes in real-time, letting both parties access accurate information from anywhere. It’ll also help by creating valuable reports for sales forecasting, an essential part of a good VMI relationship.

With inFlow, vendors can set reorder points for your inventory that automatically generate purchase orders once stock reaches a certain level. These POs would then be sent to someone at the business to review and approve before the vendor fulfills them. You could also set up your vendors as limited users in inFlow. When reorder points are reached, they can initiate stock transfers and bill you for whatever you consume at the end of a given period.

Is VMI inventory right for my business?

There’s a few signs that might indicate you should switch to a VMI system. If you frequently run out of stock or fail to meet demand, you may benefit from offloading some responsibilities. We’ve put together some metrics to consider if you’re considering switching to vendor-managed inventory.

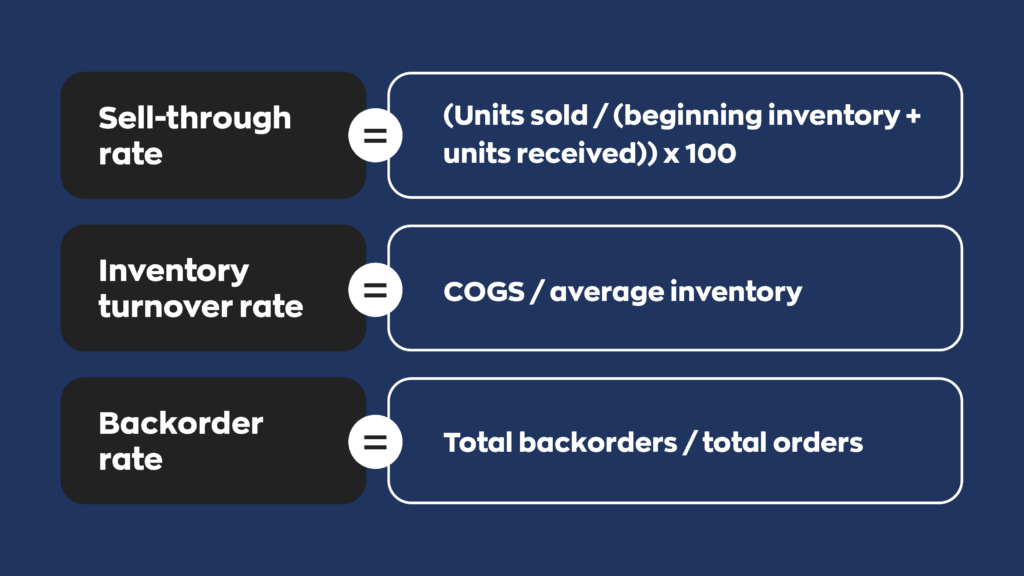

Sell-through rate

Sell-through rate (STR) indicates how much inventory you sell in comparison to how much you receive. The higher the number, the better. If this number is extremely low, that usually means overstocking. The formula for STR is simple.

(Units sold / (beginning inventory + units received)) x 100

Inventory turnover rate

Inventory turnover rate represents how quickly a business sells stock and replaces it. Higher numbers generally indicate strong sales figures, while lower numbers indicate weak ones. You’ll need to know your cost of goods sold (COGS) to calculate this one.

First, calculate your average inventory. Add the beginning and ending inventory and divide by two. Once you have that, plug the figures into the following equation.

COGS / average inventory = inventory turnover rate

Backorder rate

The backorder rate may be another reason to turn to vendor-managed inventory. The backorder rate is the number of orders a business was unable to fulfill. This number essentially records lost sales.

There can be many reasons for a high backorder rate, but poor inventory management is a common culprit. Here’s the formula for the backorder rate:

Total backorders / total orders = backorder rate

Summing up

Setting up vendor-managed inventory can be a great way to optimize your supply chain. While it may be beneficial overall, it requires a certain level of trust between both parties. It’s best to be selective and take the time to find reputable partners.

However, even with the best relationships, VMI inventory hinges on reliable data. Implementing vendor-managed inventory without proper cloud-based software is a recipe for disaster.

0 Comments