The HVAC industry plays a significant role in our daily lives. It keeps us comfortable in our homes, keeps our food fresh longer, and even preserves medicine. HVAC systems do so through a process called the refrigeration cycle. While the exact mechanisms are complex, the theory is simple.

In today’s article, we want to get back to basics for anyone working in the HVAC industry and talk a bit about the refrigeration cycle. We’ve even included a helpful refrigeration cycle diagram. So whether you’re a greenhorn just getting started in the industry or a seasoned HVAC professional, this article will give you all the information you need on the refrigeration cycle.

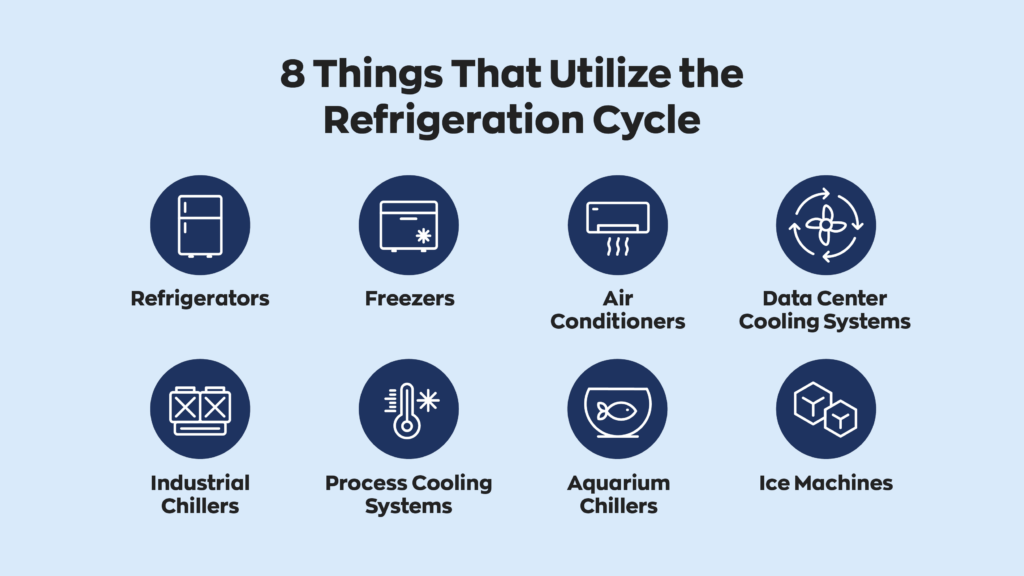

You’ve likely heard of the refrigeration cycle if you work in HVAC. After all, it’s the cornerstone of air conditioners, refrigerators, and heat pumps. The refrigeration cycle operates on the principles of thermodynamics and is typically used to cool spaces. It does this by taking heat from one area and moving it to another.

What is the refrigeration cycle?

Key components of the refrigeration cycle

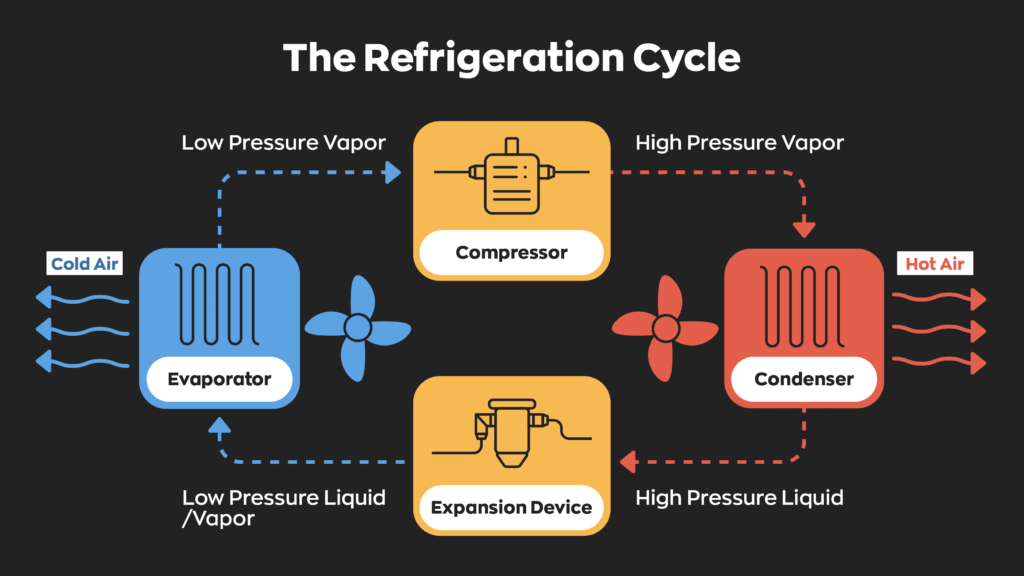

There are four main components that make the refrigeration cycle possible. They are as follows: compressor, condenser, expansion device, and evaporator. Refrigerate is also important, although it doesn’t play an “active” role. Something to note here is that refrigerant charges form throughout the cycle. Sometimes, it will be a gas and other times, it will be a liquid.

Each refrigeration cycle component has a specific role to play in the refrigeration cycle, but they all rely on one another to function. No component is more important than another. Each also represents a stage in the refrigeration cycle. You’ll be able to better observe what we mean by looking at the refrigeration cycle diagram below. Let’s take a closer look.

Now that you’ve seen the refrigeration cycle diagram let’s examine each of its components in more detail to get a better idea of how it works.

Compressor

It helps to think of the compressor as the heart of an AC system. It’s the component that pushes refrigeration from one part to another, like blood through the body. It does this by creating different pressure areas within the system.

In general, gasses will move from high-pressure areas to low-pressure areas. This makes it useful for moving refrigerant from one area of the system to another.

Condenser

The condenser takes the hot gas refrigerant from the compressor and removes the heat, turning it back into a cold liquid. It achieves this by taking advantage of heat transfer. Similar to the high-to-low-pressure movement we mentioned above, heat will generally move to colder areas. This principle is part of what turns refrigerant from gas to liquid. Typically, in AC units, the condenser is located outdoors so that the heat expelled by this process can dissipate into the air.

Expansion device

The expansion device is similar to the condenser, but instead of removing heat, it removes pressure. This doesn’t directly lower the temperature, but it does have the same effect. While this may seem like overkill, the expansion device is really what enables the refrigerant to cool your home. Heat exchange alone isn’t enough; it needs a low-pressure environment to expedite the process.

Evaporator

The evaporator is located inside and is actually responsible for cooling the environment. It does this by forcing refrigerant through an area. The refrigerant absorbs the heat and moisture from the region, resulting in cold air. From here, it goes back into the compressor.

Again, the refrigeration cycle relies on each of these components to function. If one part goes belly up, the system fails. Regular checks are an essential part of keeping things in working condition.

It’s worth noting that there are many types of compressors in use. They all have the same goal but use different methods to achieve it. Each of these methods has its own advantages and disadvantages. Some are quieter; others are more scalable. We won’t go into too much depth here, but it’s best to know the most common types. Overall, centrifugal, rotary-type, reciprocating, and dynamic compressors are the most popular.

Centrifugal and rotary-type compressors rely on rotation to build pressure, while a reciprocating compressor works more like a piston. Dynamic compressors also rely on rotation but instead use the motion to speed up an air current. This, in turn, builds pressure.

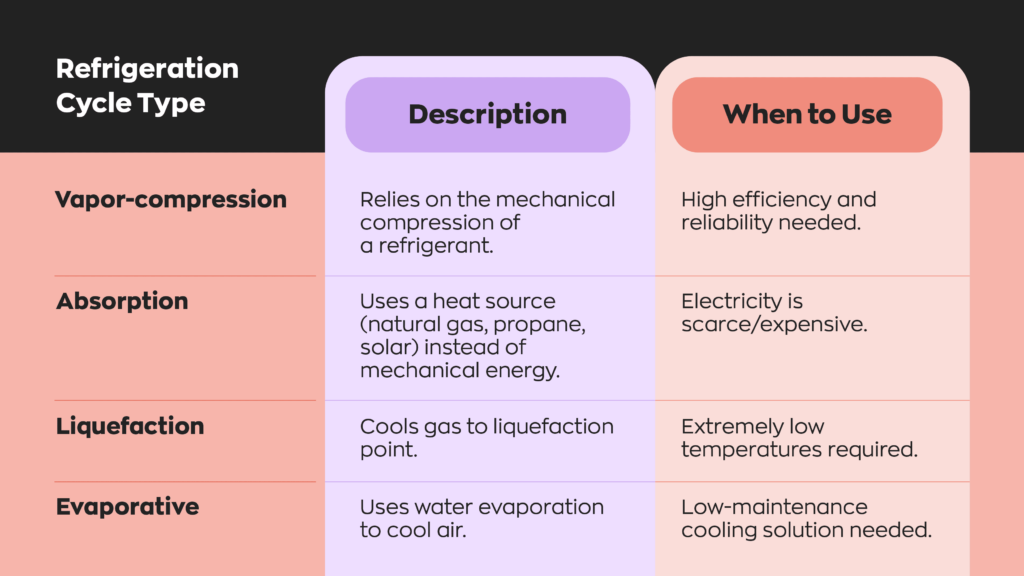

Types of refrigeration cycles

There are also variants of the refrigeration cycle. In general, there are four types of refrigeration cycles, classified according to their cooling method. It’s important to know what each is and where you can use them. Each method follows the same basic principles shown in the above refrigeration cycle diagram:

- Vapor-compression is the most common type of refrigeration. Compression systems use a compressor to lower the pressure of the refrigerant, cooling it and turning it into a liquid. From here, it moves through the rest of the refrigeration cycle.

- Absorption uses a heat source to power the refrigeration cycle. You can achieve this by breaking coolant into two separate bodies. One performs evaporative cooling, and then the second body absorbs it. A heat source is necessary to restart the process and align the coolant temperatures again.

- Liquefaction involves cooling refrigerant down so far that it becomes a liquid. This makes it easy to store and transport. In general, this is not for consumers. Its normal use case is experiments or massive industry-scale solutions.

- Evaporative refrigeration is the simplest refrigeration method. Evaporative systems work by evaporating a liquid, such as water, into the air. This effectively cools the air but can increase humidity. Rather than a man-made cycle, evaporation is part of a more natural cycle. That makes it easy to use but, in some instances, much slower.

Each method of refrigeration has its pros and cons. Some are cheaper, others are more efficient, and some might not fit a customer’s use case. Depending on the location of your operation, one method might be more effective than another. Be sure to research before adding or creating a product in your company’s catalog.

How to track your condensers, evaporators, and beyond

We’ve mentioned it a few times already, but as you can see from the above refrigeration cycle diagram, every component is an integral part of the refrigeration cycle. They all work in unison; if just one is missing, the refrigeration cycle won’t happen. And isn’t that what your customers are paying you for?

This is why proper inventory management for HVAC companies is crucial. But we get it. Field services make it hard to track inventory accurately with technicians spread out all over town. Luckily, inFlow is here to help. With inFlow, you can track your components across multiple locations with our cloud-based inventory system. This means you can set up each truck and warehouse as a separate location so you can see exactly which technicians have what.

Our field management software makes it easy to monitor your inventory levels and helps you set reorder points for your products. This means inFlow will notify you when you’re running low on something, so you’ll never run out of stock.

We also have a built-in barcoding system that makes it fast and easy for technicians to remove items from their trucks and update their inventory in real-time. Once the job is complete, technicians can use inFlow to create the invoice and bill the client right from the job site.

0 Comments