There are two methods for tracking and accounting for your products: the periodic and perpetual inventory systems. The periodic inventory system is easier to start out with because it is less complex. However, we’d suggest the perpetual inventory system for all but the smallest of businesses. Perpetual inventory systems are more accurate, and they provide better traceability in the event you need to audit.

In this article, we’ll dive into perpetual vs periodic inventory systems, how they work, and what sets them apart.

What is a periodic inventory system?

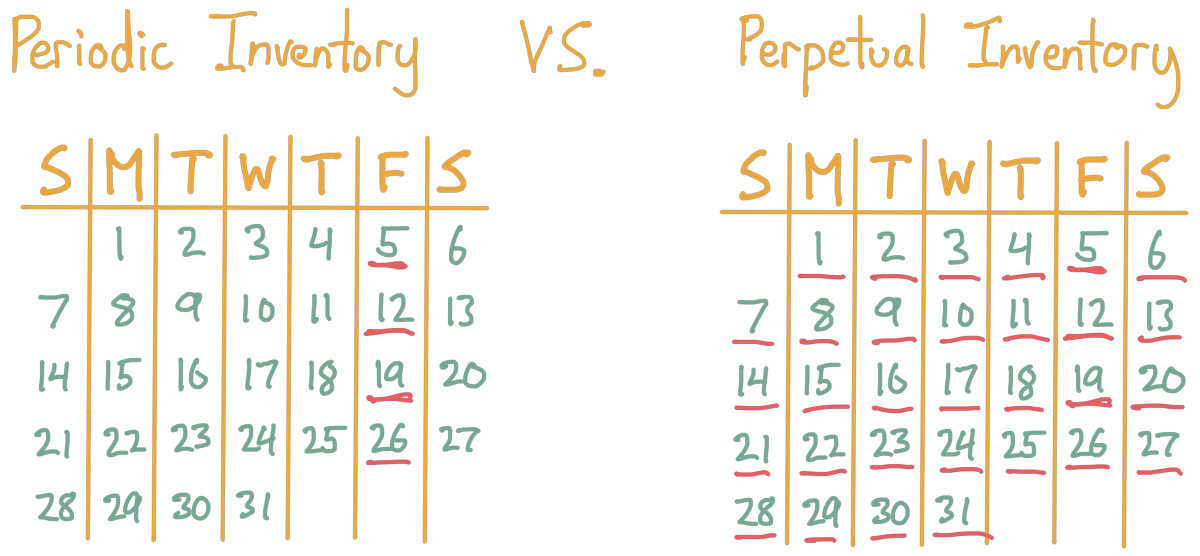

The periodic inventory system involves counting inventory and inventory value at regular intervals, like a series of checkpoints. Depending on the business, this means that inventory counts occur on a weekly, monthly, quarterly, or even annual basis.

It’s common for businesses to use a periodic inventory system at first because it’s straightforward: you buy products for a set amount of money (beginning inventory), purchase more inventory when needed, and then count your products at the end of the period (ending inventory). You then use those three numbers to calculate the cost of goods sold (COGS) during that period.

Written as a formula, here is how you’ll find the cost of goods sold while using a periodic inventory system:

The upside of a periodic inventory system is that it doesn’t require any special equipment or inventory software — just paper or a spreadsheet to track the numbers. Time is the major consideration when dealing with a periodic inventory system and how often your business will run an inventory count.

Usually, businesses must shut down their operation entirely to conduct a cycle count. Doing this regularly will eat into productivity and cost your business in the long run.

Generally speaking, periodic inventory systems are best suited for companies with low sales volumes and very few things to track.

Cycle counting at intervals

Weekly counts allow you to easily spot irregularities in inventory due to theft or breakage. However, weekly counts take more valuable time out of the work schedule. Full inventory counts involve tallying all products in every storage location at the end of the week in order to know how much stock you have going into the following week.

You can extend the interval between counts to a month or a quarter, but this reduces overall inventory accuracy. Going long periods with no visibility into actual stock counts could end up causing you serious issues. After all, it’s tougher to remember what happened earlier in the month rather than earlier in the week. These longer intervals also make forecasting and reordering more difficult because it isn’t obvious when you need to reorder products. That lack of information compounds further if you manage the inventory for multiple locations or stores.

If you’re using a periodic inventory system, you’ll need to reach a balance between low accuracy with infrequent counts and high accuracy with frequent counts. Essentially the longer you wait between cycle counts, the more you’ll increase your margin of error. This is where the advantages of a perpetual inventory system become more evident.

What is a perpetual inventory system?

While periodic inventory systems can go through weeks or months without a complete count, a perpetual inventory system records each inventory movement (or transaction). This includes purchasing or selling products and transferring products between locations. By tracking each of these transactions, your business can always answer the question, “how much stock do we have?”. A perpetual inventory system will also improve your ability to accurately forecast and reorder because you’ll know exactly when (and how often) a product has sold out.

Think of it like this. Using a perpetual inventory system would be like having a live video feed of your stock room. You’ll be able to see exactly what you have at any given moment. A periodic inventory system would be like if you took a photo of your stock room at regular intervals. You’d be making estimations on what you have on hand based on the last photo that was taken. Sure, you could make an educated guess based on past photos, but there is no way of knowing for sure.

Keep in mind you should still run full inventory counts under a perpetual inventory system, but you can drastically reduce their frequency. The bulk of the work is done at the transactional level — recording things as they happen. Cycle counts conducted under a perpetual inventory system are just a way to verify stock levels against your database. Having a fully barcoded inventory system makes the tracking process accurate and easy. When you purchase, sell, or move a product, you can scan the corresponding barcode into inventory software like inFlow Inventory. This process ties the product to a particular set of orders and gives you complete traceability.

Larger businesses with high sales volumes, multiple locations, and extensive inventory lists should always use a perpetual inventory system.

Tracking COGS with a perpetual inventory system

Using a perpetual inventory system also changes how you calculate the cost of goods sold (COGS). Because beginning inventory, ending inventory, and purchases are tracked on an ongoing basis, you can calculate the COGS at any time. The moving average costing method and the FIFO/LIFO costing method are two common methods of tracking COGS.

Why switch to inFlow?

It’s true that it does take more equipment and planning to use a perpetual inventory system. But that doesn’t mean it has a significant barrier to entry.

Barcode scanners are available for under $100. Good barcode printers like the Dymo LabelWriter 450 cost less than $150. And inFlow Inventory subscriptions start under $100 per month. When compared to the money spent on staff for frequent cycle counts, the costs start to even out.

If you’d like to upgrade your inventory system to record changes as they happen, inFlow Inventory can help!

I’d be happy to upgrade my inventory system soon, so I’ll contact you if any questions appear. Kind regards,