Imagine running a sale on your website. You’ve been hyping it up, and your customers are ready to buy. The sale goes live and your hopes are high.

Suddenly angry emails start pouring in, and past customers start complaining about your brand on social media. You quickly realize the stock you thought you had ready to go is nowhere to be found. Your inventory management was insufficient, and your lack of forecasting led to this disaster.

Maybe you’ll never run into a problem of this magnitude, but poor inventory forecasting can affect your business in monumental ways over time. It can impact your cash flow, damage your reputation, and frustrate your customers to no end—sending them straight to your competitors.

We cover demand forecasting in our new podcast. Checkout the video below for a quick overview!

If you struggle weekly with managing stock, you’re not alone. It’s something we see often happen in small businesses. The truth is, smarter inventory forecasting can help you work a lot of kinks out of your process.

Today, we’re covering the basics of inventory forecasting: what it is, how it can benefit your business, how to do it, and useful methods and features to consider adding to your routine.

Work smarter instead of harder when it comes to managing your inventory with forecasting. It’s the tool you need to refine your purchase orders and cut unnecessary costs in your business.

What is inventory forecasting?

The definition of inventory forecasting is predicting how much inventory you need to order at what time. Accurate inventory forecasting can help you plan for future product demands, cut costs, and boost revenue. Forecast how much inventory you’ll need by factoring in sales history, trends in demand, and average lead time (from ordering to delivery) for new stock.

Forecasting is an essential part of managing inventory. It will help you set more realistic goals for your business and manage your budget better.

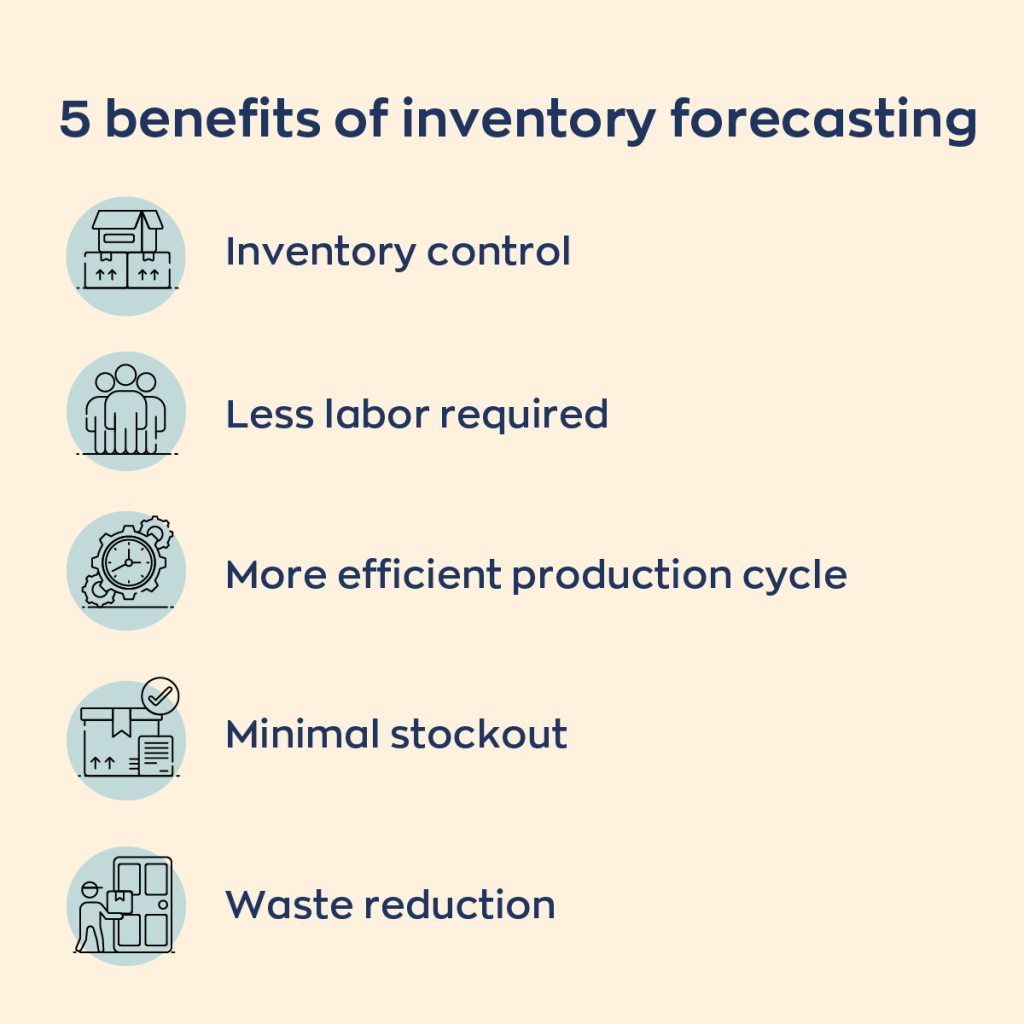

Top benefits of inventory forecasting

Here are five ways that forecasting inventory can help your business thrive.

Forecasting can help control inventory.

Forecasting helps you determine how much inventory you’ll need for a specific period in the future. It will help you identify the right amount of stock to keep on hand. You won’t have to tie up as much money into inventory holding costs, either. You’ll know how much space you need and won’t waste money paying for extra.

Your business will require less manual labor.

Using the right inventory forecasting tools, you can automate tasks that would otherwise require manual labor. Forecasting sales, revenue, and costs in one place can help you more accurately project future sales. You’ll also avoid the need for extra hands on deck if you project demand for products accurately.

Your production cycle will be more efficient.

Forecasting can also increase supply chain efficiency. Scheduling with your production, warehousing, and shipping suppliers will be timelier. And you can contact partners when you foresee a spike in demand to ensure they have enough stock available.

You’ll minimize stockouts.

A stockout is when you run out of inventory. When this occurs, your sales can fall, and your customers could become frustrated with your business.

When you forecast correctly, you won’t run into this problem. You can fulfill orders promptly as they come in and deliver items to customers as promised. Your customers will be happier and won’t have to turn to a competitor to get what they want when they want it. Forecasting improves the overall customer experience.

You can reduce waste.

You’ll know which products sell best and which ones are slow to turn a profit. That way, you can plan accordingly for future orders and free space for high sellers to increase revenue.

How to do inventory forecasting

To forecast how much inventory you’ll need, consider several important factors: your sales history and trends, average lead time, base demand, reorder point, and safety stock. We’ll start by defining some standard terms you’ll run across to help you better understand the inventory forecasting process overall.

Knowing these definitions will help you more easily calculate critical pieces of the forecasting puzzle to determine future needs more accurately.

- Forecast period: This is the timeline you’ll use to figure out how much inventory you need to order. You may base it on your production cycle and turnover rate. Your forecast period might be 30, 60, or 90 days.

- Average daily sales: To calculate your average daily sales per unit, divide the number of sales during your forecast period by the number of days in that same timeframe.

- Lead time: Your lead time is how many days it takes for you to receive inventory after ordering from a supplier.

- Reorder point: This will tell you at which level you must replenish your stock to avoid running too low.

- Sales trends: These will change often. Keeping track of how sales change over time will help you predict customer buying habits and patterns throughout the year.

- Safety stock: This is your safety “buffer” to ensure you don’t run out of products early. Having too much inventory can be a waste of money and space. Having too little can get you into trouble if you sell out of something faster than expected.

- Maximum stock level: This is the maximum number of items (of one SKU) that fit on your shelf when fully stocked.

- Days sales of inventory: This is the average number of days it takes you to sell off stock.

How do you calculate inventory forecasting?

Here are some essential formulas to help you manage inventory forecasting in your business.

Pro tip: Having 1) backorder reports, 2) end-to-end inventory tracking (from the first quote to product shipment), and 3) reports estimating how long current stock will last can help you calculate inventory forecasting faster and more accurately.

1. Calculate your lead time demand.

Multiply your average lead time by your average daily sales for a single product. Use historical sales data and how long your vendors have taken to fulfill orders in the past to fill out the formula.

Let’s say, for example, that you sell five umbrellas a day, on average. And it takes ten days for your vendor to deliver your regular umbrella order, on average.

Lead time demand (LTD) formula

LTD = average daily unit sales x lead time (in days)

5 umbrellas x 10 days = 50 umbrellas

In other words, you’ll need 50 umbrellas in stock when you’re waiting for your vendor to fulfill your order to ensure you don’t run out before it arrives.

2. Determine your safety stock.

To calculate safety stock, take the maximum number of units you’ve sold in one day for an item and multiply it by your maximum lead time (the longest it’s ever taken your vendor to fulfill your order). Next, multiply your average daily sales by your average lead time (in days).

Then take the product of your first calculation and subtract that of the second. This will give you your safety stock level.

Pretend your biggest umbrella sales day was 16, and the longest it’s taken your vendor to deliver an order has been 14 days.

Safety stock formula

Safety stock = (maximum daily sales x maximum lead time) – (average daily sales x average lead time)

(16 umbrellas x 14 days) – (5 umbrellas x 10 days) = 174 umbrellas

You’ll need 174 umbrellas on hand as a buffer to ensure you don’t run out if something out of the ordinary occurs – like two straight weeks of rainy weather.

3. Set your reorder point.

Your reorder point will fluctuate based on market conditions and sales trends. You’ll adjust it frequently. To calculate, multiply your average daily unit sales by your lead time, and then add your safety stock.

Reorder point (ROP) formula

ROP = safety stock + (average daily unit sales x lead time)

174 umbrellas + (5 umbrellas x 10 days) = 224 umbrellas

To avoid risking running out of an item too soon, replenish your stock when you reach this point. In this example, you’d reorder when you’re down to 224 umbrellas.

4. Calculate your reorder quantity.

It’s time to reorder a popular product. But how do you know how much to order? You guessed it – we have a formula for that. Ordering the right amount of inventory at the right time is crucial to cutting unnecessary costs and keeping customers happy.

Reorder quantity formula

Reorder quantity = average daily unit sales x average lead time

5 umbrellas x 10 days = 50 umbrellas

Look familiar? It should! It’s the same basic formula as lead time demand. Next time you place an order for the upcoming period, request 50 umbrellas from your vendor.

What are the main methods of forecasting?

Here are some of the most common forecasting methods to help you plan, order, and store the right inventory amount.

- Trend forecasting: This method takes past sales and market growth into account to predict future sales trends.

- Qualitative forecasting: If historical sales data isn’t helpful or relevant (e.g., with a startup or new product), you can predict demand for a product based on current market demand.

- Quantitative forecasting: This model uses historical sales data to predict future demand, making it an ideal method for well-established businesses.

- Graphical forecasting: You can repurpose your sales data into a visual form to make it easier to understand and identify trends or patterns.

Helpful inventory forecasting tools

To keep track of how your products perform and make inventory forecasting easier, consider the following tools.

- Excel: Basic spreadsheets are usually only adequate for tiny businesses with few products. You can use Excel to load formulas and perform calculations. Keep in mind that it will only give you a static projection of your future needs rather than a dynamic forecast that automatically pulls data and updates.

- Inventory management software: If you’re a small business, you’re likely fulfilling orders yourself. Even if you’re outsourcing to a 3PL, inventory management software may still be necessary to forecast your needs successfully. Modern software systems have the tools you need to predict and monitor your inventory needs accurately. You can also run reports to keep track of how your products perform and understand how your business works on a deeper level.

- Third-party logistics (3PL): If your business grows to the point where you need large quantities of products to meet ever-growing demands, consider outsourcing fulfillment to a 3PL provider. A competent company should have the tools and software to forecast inventory needs.

inFlow can help you do inventory forecasting like a pro

The formulas in this article are pretty straightforward. The tricky part is adjusting your efforts to changing demands – which can be almost constant. That’s where inventory management software comes in clutch.

inFlow is a powerful, easy-to-use inventory software system that will crunch crucial numbers for you so you can spend your time on other essential tasks. The program will show you what’s in stock, what’s on order, and what you need to restock when. It’s accessible on any wireless device, so you can check your inventory levels often and wherever.

0 Comments