Inventory management helps businesses take control in a way that suits them. Putting the right system in place can seem like a big task, but using barcodes and QR codes in stock control is easier than you might think. We take a look at QR codes vs barcodes for inventory management and what each really means.

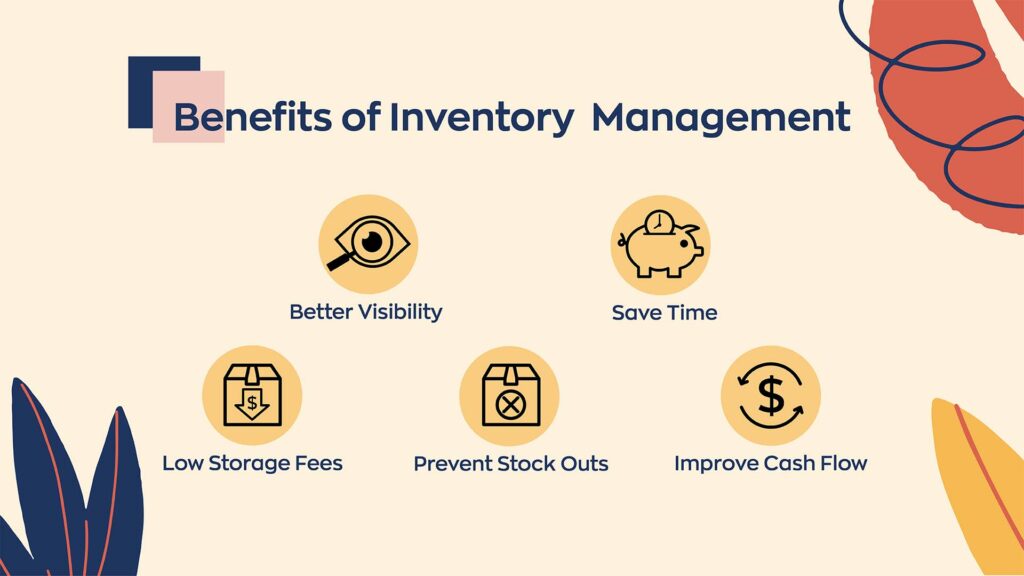

Why inventory management matters

Before deciding whether to use traditional barcodes or QR codes, it’s important to determine what you want your business to achieve. To do that, we need to think about why good inventory management matters.

Inventory systems can be complex. There are a lot of stages and moving parts involved that influence your business. This includes how much stock you purchase, store, and sell and where and when that happens.

Let’s take a look at what could happen without managing this process well. Imagine you’re a clothing retailer, and an input error leads you to order a shipment of the wrong sweater. There may not be any immediate financial impacts.

However, soon after, another product, let’s say a pair of sneakers, suddenly sells out. Ideally, you would order a larger shipment of the sneakers next time to avoid disappointed customers. Unfortunately, there are still too many boxes of sweaters in the warehouse and no space for the extra stock.

So, not only would you lose out on sneaker sales, but the extra boxes start to become damaged as you move them to try and create more space. This has cost time, money, and customer loyalty, all of which you could avoid with good inventory and warehouse management.

What does inventory management do?

Inventory management can help businesses by controlling various stages. As IBM explains, “The goal of inventory management is to have the right products in the right place at the right time.” Having the right amount of products from the right sources is also essential.

This also helps your business make informed, real-time decisions and forecasts based on inventory facts.

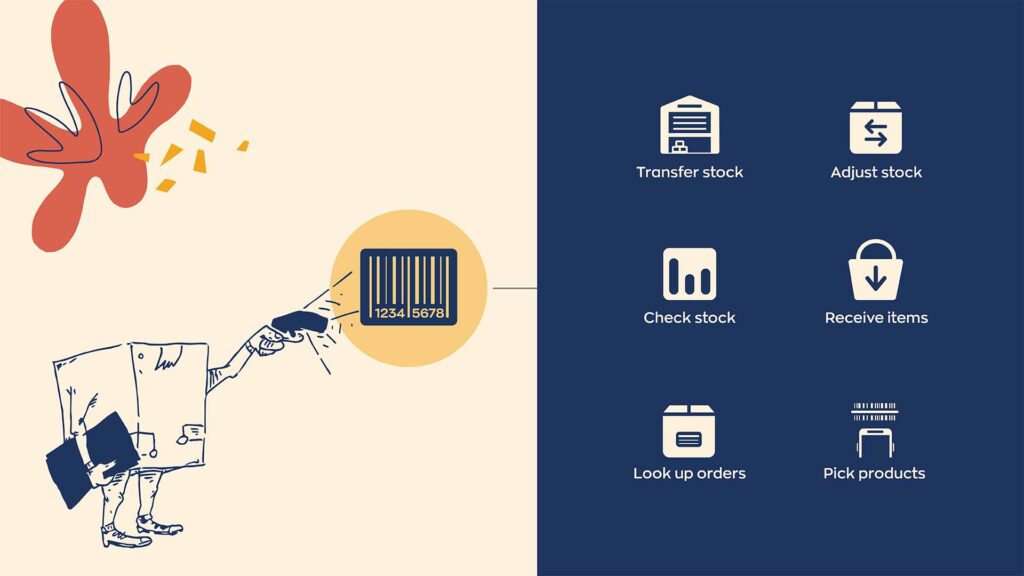

How are barcodes used for stock?

A lot of people use the word barcode as a catch-all phrase. In reality, it refers to the black-and-white lines or squares that we scan. On a traditional, one-dimensional barcode, these lines are a machine-readable representation of the number that appears underneath (sometimes called GTIN).

Assigning a barcode and number to a product means you can scan it quickly for any number of reasons, including accurately:

- checking stock

- receiving an item into inventory

- adjusting stock

- picking products

- looking up orders

- transferring stock from one location to another

This can save time and reduce errors as employees move away from manual data entry. It also means that you can scale up your inventory operations as your business grows without changing your system.

You can choose to generate your own barcodes or go through GS1, which provides standard barcode numbers for international use. From there, you can scan these with a phone or scanner through barcode software like inFlow.

We partnered with GS1 to make our official inFlow GTIN Barcode Shop to make it easy for our customers to buy a single barcode for only $30 with no renewal fee.

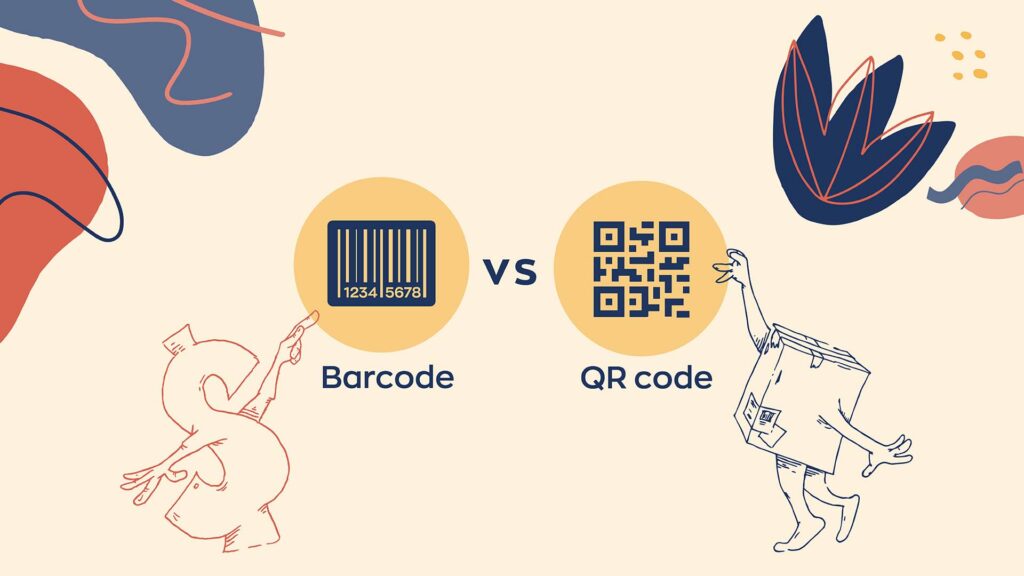

1D barcode vs QR code

As you look into using barcodes for inventory management, chances are you’ll come across the terms 1D barcode, 2D barcode, and the well-known QR code. So, what’s the difference between QR codes vs. barcodes for inventory management?

One-dimensional (1D) barcodes are the ones we’re used to seeing on all manner of products. They have vertical black lines and spaces and can usually only encode a small number of numeric characters. This means the amount of information they hold is limited.

On the other hand, two-dimensional (2D) barcodes are more versatile. QR (quick response) codes are a type of 2D barcode. They have a more intricate pattern of black and white squares that allows them to hold a broader range and a more significant amount of data. This means they can point someone to a website or other source of information. You can also scan them from more than one direction.

QR codes: a quick history

QR codes might have become very popular in the last few years, but they’ve been around for longer than you might think. In fact, they were invented to solve an inventory problem.

Over two decades ago, Japanese company Denso faced difficulties in managing its expanding range of automobile parts. Engineer Hara Masahiro was on his lunch break, playing his usual game of Go, when he was struck with an idea.

As reported in PapersOwl, he explained, “One day, while arranging the black and white pieces on the grid, it hit me that it represented a straightforward way of conveying information. It was a eureka moment.” The technology was then developed and has now spread around the world.

Today, we use QR codes for everything from inventory to tracing people who have come into contact with Covid-19, thanks to the extra information they hold.

In fact, a UK and US survey from September 2020 showed that 37.7% of respondents had scanned a QR in a restaurant, bar, or café in the previous six months. Meanwhile, 37.3% had scanned one at a retailer and 31.8% on a consumer product.

QR codes vs. barcodes for inventory management

Before starting to use a barcode system, it’s a good idea to decide which type of barcodes suit your business best.

1D barcodes can hold basic information and are highly useful for inventory control. However, QR codes can do all the same things as a traditional barcode, except they are capable of even more since they can encode more information, such as URLs. You can also scan them from any direction, which can make them quicker to work with.

What’s more, QR codes have a level of error correction that means they may still be readable if there is slight damage or wear and tear. When contemplating QR codes vs barcodes for inventory management, you’ll need to consider software. With our software inFlow, you can scan both QR codes and 1D barcodes via a smartphone or with a scanner. Keep in mind, though, that not all scanners can scan QR codes, but if you’re looking for one that can, look no further than our inFlow Smart Scanner.

The future of barcodes

It’s also a good idea to look at what’s to come. The organization GS1, a neutral provider of standards in various industries, sees the future in 2D barcodes.

They have launched a program called Sunrise 2027, which aims to help businesses transition fully to using 2D barcodes at retailer point-of-sale by that year. They explain that “2D barcodes allow for a single, standardized way to meet both supply chain needs and evolving consumer requirements.”

Generate, print, and scan barcodes with inFlow

While barcodes are an incredibly powerful tool, they’re only as good as the software you use them with. This is why we designed inFlow with a built-in barcode system. Whichever type of barcode you decide to use, our software can help you put your new system in place quickly and easily. With inFlow, you can generate, print, and scan 1D barcodes and QR codes straight from our app.

We even have a brand new label designer tool for you to create custom labels to place your newly minted barcodes, along with your logo and any other information you want to provide. You can generate QR codes that link to your products within inFlow, or you can link them to a URL. It’s completely up to you.

If you want to learn more about barcoding your small business, you can check out our Ultimate Barcoding Guide. It covers everything, and we mean EVERYTHING you need to know about getting started with barcodes.

So what Barcode /QR system do you recommend?

Hey Gerhard,

Well I may be biased but I would recommend inFLow if you’re looking to implement a barcoding system. You can even get started by just using your phone as a scanner and an inkjet printer for your labels, if money is an issue. And best of all inFlow has a 14 day free trail so you can try it out and see if it’s a good fit. Our onboarding team is super helpful and could get you up and running in no time.

Hope this helps,

Jared

Hello,

I am considering using inflow for my small business.

I saw that inflow can generate barcode, is it right?

Can it generate QR code as well?

As QR code seem more convenient for us

Awaiting your reply

Thank you

Bryan

Hey Bryan,

Thanks for reaching out. To answer your question, inFlow can indeed generate barcodes! At the moment inFlow doesn’t generate QR codes, however, that’s going to change very soon as we’ve been developing a brand-spanking new barcode generator and label designer. If you want to learn more about how inFlow works with barcodes checkout our barcoding features page. You can also reach out to our sales team and they can answer any specific questions you might have.

Cheers,

Jared

Hi, how is progress with the QR feature mentioned in the reply above?

It’s the main feature holding me back from moving from Sortly to InFlow.

Hey Samudra,

Thanks for reading. To answer your question we released our built-in label designer back in March which allows you to create QR codes. So if that was the only thing holding you back, now’s the time to make the switch!

Cheers,

Jared