Key takeaways

- Inventory visibility refers to the ability to track inventory levels, movement, and status in real-time across all business locations.

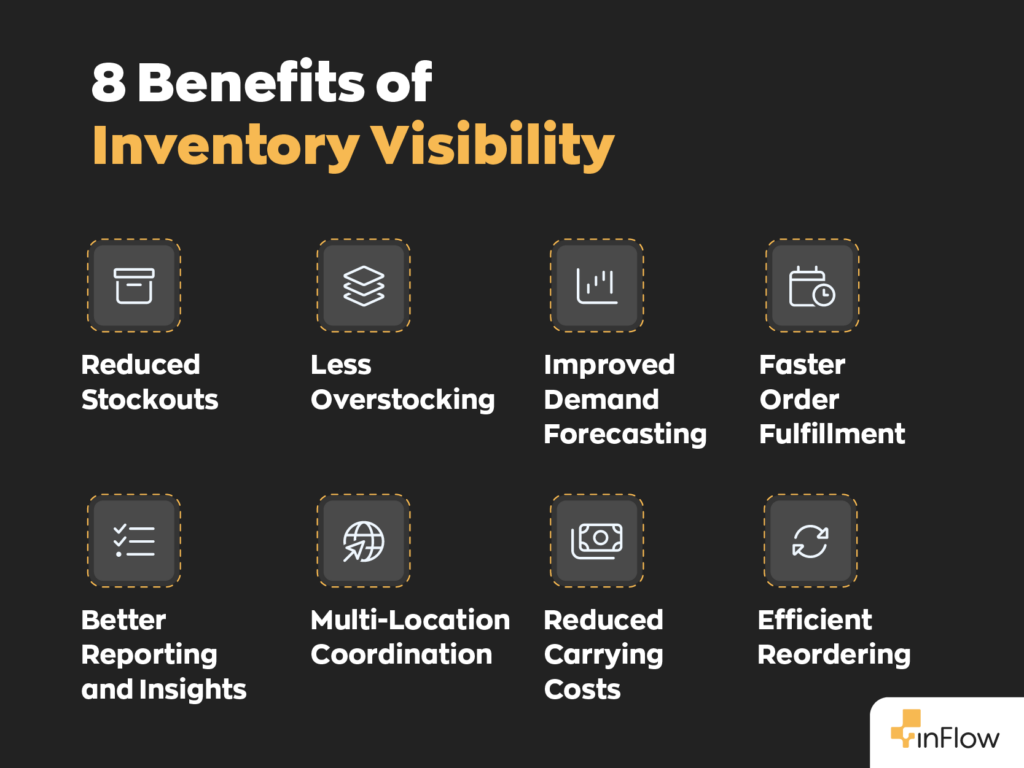

- It reduces risks such as overstocking and stockouts, improves demand forecasting, and aligns data across different departments and locations.

- Inventory management software provides real-time insights, automates manual tasks, and integrates with other systems (like accounting or ecommerce) to streamline operations and reduce errors.

- Common challenges include human error, siloed systems, poor communication, outdated tech, and lack of standardized procedures.

- To improve visibility, businesses should centralize their inventory data, conduct regular audits, train staff, set automated reorder points, and utilize tools such as barcoding.

Inventory visibility is an organization’s ability to track and monitor its inventory in real time across all its locations, including warehouses, stores, and distribution centers. This means having an accurate, up-to-date view of inventory levels, movements, and status at any given moment.

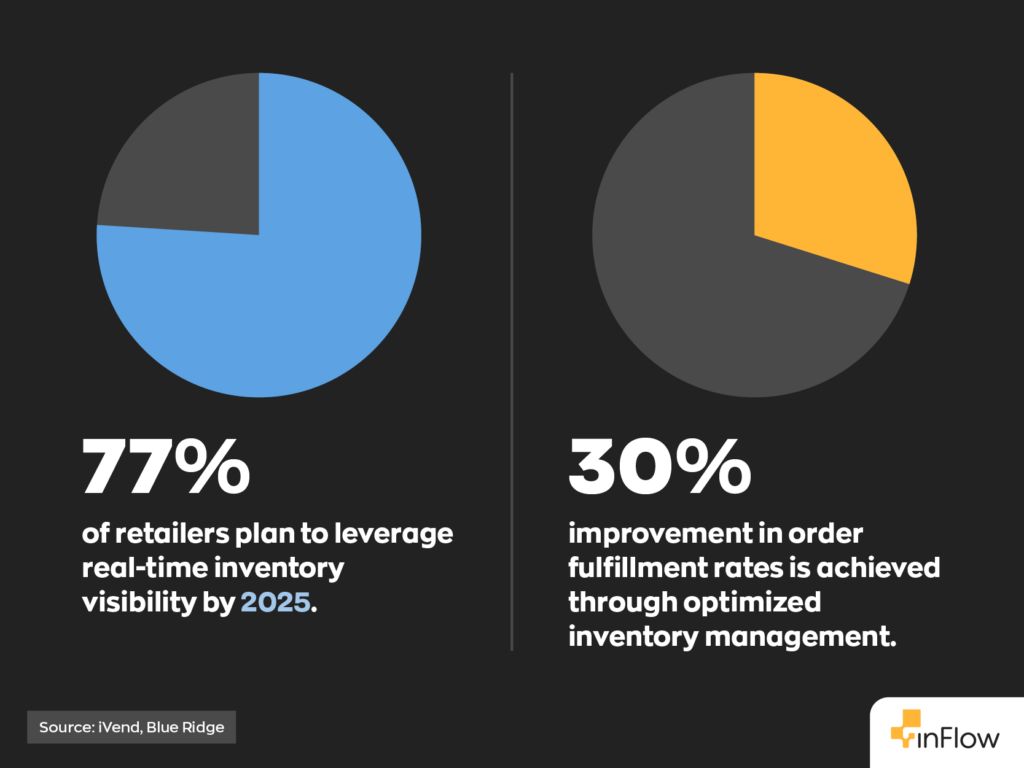

Inventory visibility is crucial for businesses because it facilitates better decision-making, better customer service, and boosts overall operational efficiency. With accurate inventory data, businesses can reduce overstocking and stockouts, optimize supply chain management, and respond accordingly to any changes in demand.

The importance of inventory visibility

Inventory is a core component of a business’s assets, and how an organization handles its inventory can directly impact its financial and operational performance. By providing an up-to-date picture of stock levels and movements, inventory visibility can directly enhance forecasting, planning, and demand fulfillment.

This allows companies to make informed decisions regarding purchasing and production, mitigating the risks of overstocking or stockouts. With precise data on current inventory, businesses have a better idea of customer demand and make adjustments if needed, which results in using resources and capital more efficiently.

Further, accurate inventory visibility supports effective communication among various departments, ensuring that marketing, sales, and supply chain operations are aligned and responsive to market dynamics. As a result, companies can easily find ideal inventory levels, allowing them to avoid unnecessary carrying costs and increase customer satisfaction by reliably meeting their demand.

Benefits of inventory visibility for growing businesses

Inventory visibility offers numerous benefits for growing businesses by enhancing their operational efficiency and decision-making capabilities. Accurate and real-time access to inventory levels helps avoid expensive issues like overstocking and stockouts, which can hinder young companies’ growth.

Increased visibility also allows for more effective demand forecasting and resource allocation, giving new businesses a better understanding of customer expectations and industry trends. Through these insights, businesses can provide better service to new customers, resulting in lasting positive impressions that foster continued loyalty.

For businesses without prior experience, inventory management can seem complex. Fortunately, inventory management software makes it easy to streamline the process. These systems provide real-time data and analytics, so businesses can make informed decisions about purchasing, sales strategies, and demand forecasting.

Further, automating manual inventory management tasks helps cut down on potentially costly mistakes. Additionally, inventory software often integrates with other business systems such as accounting and ecommerce platforms, ensuring seamless operations and data consistency across the organization.

Common inventory visibility challenges

Maintaining inventory visibility can be difficult due to several notable challenges, including:

- Human error: Human mistakes during manual data entry—such as incorrect counts, mislabeling, and misreporting—can lead to inaccurate stock levels, misplaced items, and inefficiencies in order fulfillment.

- Siloed systems: Multiple systems that don’t communicate (e.g., spreadsheets, disconnected software) create “silos” of information, making it hard to get a consolidated, accurate view of inventory.

- Poor communication: Similarly, if staff from different departments (like sales, warehouse, procurement, and finance) don’t share or synchronize information, it can result in mismatched forecasts, over-purchasing, or missed sales due to stockouts.

- Inadequate technology: Outdated or poorly implemented inventory software, or a lack of automation tools like barcoding or RFID, can limit an organization’s ability to track stock efficiently and scale operations.

- Lack of standardized procedures: When different locations follow inconsistent processes for receiving, recording, and managing inventory, it creates confusion and inconsistency in inventory records, especially when transferring items between locations.

It’s essential to identify and promptly address any notable inventory issues within your organization, as poor visibility can result in serious problems like overstocking, shipping delays, and lost revenue, which can leave lasting impacts on your organization.

How to improve inventory visibility with the right tools

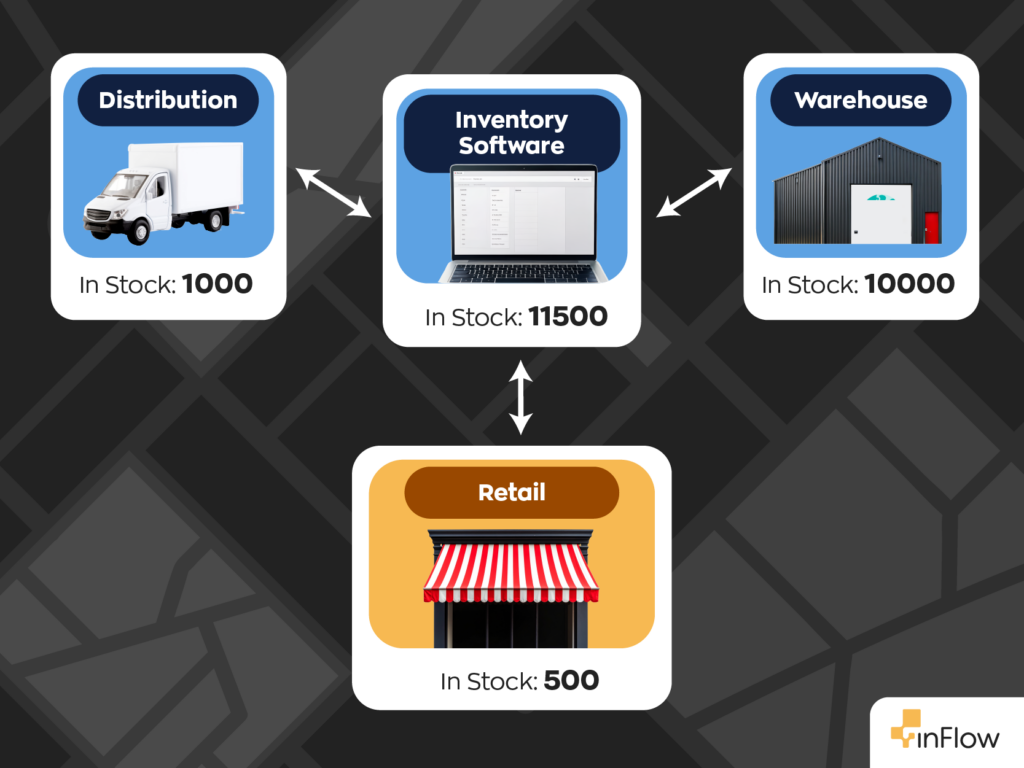

Automated tools like inventory software can significantly enhance visibility across multiple locations by providing real-time data and centralized control. These systems enable businesses to track stock levels, manage orders, and predict demand efficiently by leveraging automated processes that minimize human error.

With integrated platforms, data from various warehouses or stores is synchronized and made easily accessible, allowing for accurate updates on stock movements and availability. This comprehensive visibility ensures that inventory is optimized to meet customer demands, reduce excess stock, and prevent stockouts, ultimately leading to more efficient operations and better decision-making.

These platforms are designed to meet the differing inventory management needs of different organizations. For example, inFlow manufacturing software allows you to control every stage of the process with greater precision, from generating the bill of materials to estimating build times and labor costs, which can help manufacturers prevent the waste of raw materials and fulfill orders more efficiently.

However, organizations in other sectors may need different tools to suit their needs. Wholesale inventory software, for example, is designed to monitor unit stock levels in units and track the cost of goods sold (COGS) for every transaction, making it easier to identify inefficiencies in your process. Wholesalers can also set automatic reorder points for individual products, ensuring they never have too much or too little of anything.

Additionally, barcoding — the practice of assigning a unique machine-readable code to each asset — is an essential part of inventory management for organizations in many sectors. An efficient barcoding system can allow for quicker audits and inventory checks, enhance traceability, and reduce the risk of manual data entry errors.

Strategies to improve inventory visibility across locations

Managing inventory across multiple locations requires a significant level of oversight and coordination. Even if you have the latest technology at your disposal, issues can still arise if you don’t implement the right strategies. Efficient methods for improving inventory visibility include:

- Conduct regular audits: Frequent inventory audits help detect discrepancies early, maintain accuracy, and reduce the disruption of full physical inventory. This increases confidence in inventory data and supports better decision-making.

- Centralize your data: Using a centralized, cloud-based inventory management system gives real-time visibility into stock levels at all locations. It reduces errors from manual data entry, ensures consistency, and allows informed decision-making company-wide.

- Train staff on best practices: Even the best systems can fail with poor human input. Ongoing staff training ensures employees follow procedures correctly, leading to more accurate records and fewer operational issues.

- Automate reorder alerts: Setting automated reorder points for each location ensures timely restocking. Automation reduces the risk of human oversight, maintains consistent stock levels, and avoids costly delays in fulfillment.

- Integrate inventory with other data: Integrating inventory with data from other departments (sales, procurement, accounting) improves efficiency, reduces double entry, and helps track the actual cost and performance of inventory from purchase to sale.

- Allow mobile access to stock data: Allowing field and warehouse staff to access stock data on mobile devices can prevent errors and make it easier to share important real-time updates as they arise, leading to increased productivity and optimized inventory levels.

Final thoughts

Inventory should be viewed as a core business component because it directly impacts a company’s ability to meet customer demand and maintain operational efficiency. Ultimately, accurate tracking can lead to improved financial performance and streamlined workflows. Given these factors, understanding and managing inventory effectively is essential to sustaining and growing a successful business.

0 Comments