Key takeaways

- Demand forecasting uses historical, market, and operational data to estimate future inventory needs over short- or long-term horizons.

- Accurate forecasts improve inventory planning, cash flow, decision-making, and customer satisfaction by minimizing stockouts and excess stock.

- There are multiple forecasting types, including passive, active, short-term, long-term, internal, external, and AI-driven; each suited to different business sizes, data availability, and growth goals.

- Poor or insufficient data is the biggest risk, especially for new businesses, which is why many companies rely on software, integrations, and AI tools to improve accuracy.

Demand forecasting is the process of using data to predict the volume of inventory you’ll go through within a certain period. This period can range from as little as three months to as long as four years. Though it can be a complex process, demand forecasting is a highly beneficial inventory management practice that can help organizations in a wide variety of sectors reduce overhead costs and increase revenue.

It’s important to keep in mind, though, that the figures generated by demand forecasts are just estimates. Your actual inventory levels could dip below and just as easily blitz past the prediction. Whatever the case, it’s important to prepare in advance. Incorporating various supply chain optimization tools can further refine these predictions, enhancing accuracy and responsiveness in inventory management.

What are the types of demand forecasting?

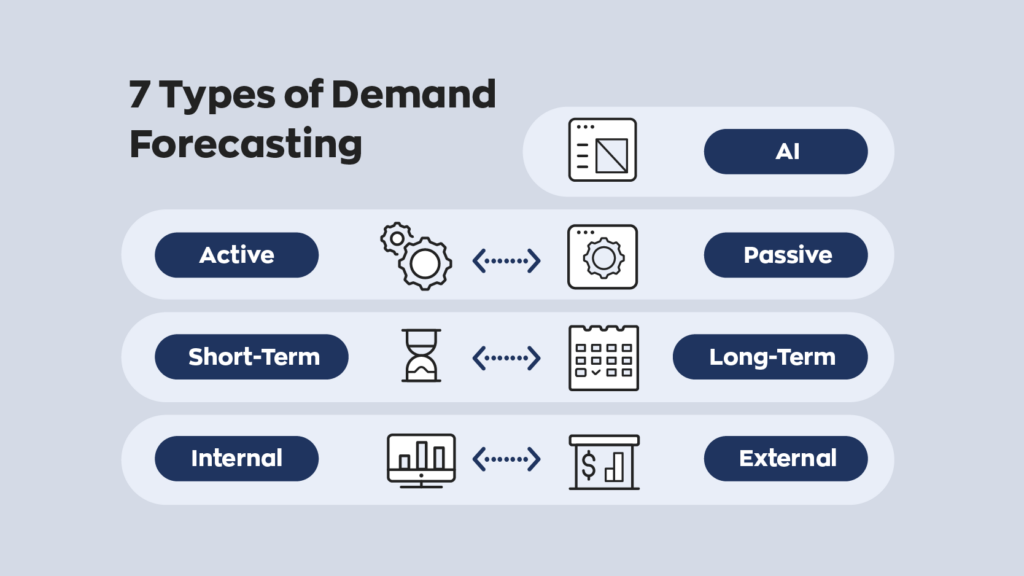

Of course, given how much information businesses have at their disposal, there are different types of demand forecasting. Generally speaking, there are seven different demand forecasting types you should be aware of:

Passive

Passive demand forecasting is the most straightforward way to forecast product demand. Unfortunately, it also requires pre-existing data to work off, making it impractical for start-ups. Passive demand forecasting works off the idea that the current year’s sales will be similar to last year’s. As a result, it caters more to businesses that prioritize stability over expansion.

Active

Active models are much more complicated. They take into account current marketing campaigns, market data, and expansion plans. They also consider external factors, such as economic viability, market growth, and more.

Newer businesses, such as start-ups, often use this type of demand forecast since they don’t have as much historical data, or any for that matter, to reference. As a start-up, when you use active demand forecasting, you’ll also have to rely on some assumptions to complete it. So tread carefully!

Short-term

This is what we were talking about when we mentioned time periods. Short-term demand forecasting attempts to predict sales volume within 3–6 months. Because of the relatively short period of time required, businesses usually use short-term models to make decisions regarding just-in-time (JIT) products.

Long-term

As the name suggests, long-term demand forecasting works over a longer period of time, usually 12–48 months. And, unlike some other methods, it focuses on shaping future growth. As a result, it may be better to think of this type of forecasting as a roadmap or a long-term goal.

You can get a pretty good idea of where things will be in four years, but the future is always uncertain. At the same time, business growth sometimes just relies on “opportunity.” Be sure you’re ready to take advantage of it when it shows.

Internal

Internal demand forecasting deals with the internal capacity of a business. Growth is often the overarching goal, but not every business is capable of growth. Can you handle increased demand? Is your operation scalable? Can your cash flow keep up with that scalability? Internal models use all these variables and more to create realistic predictions.

Some businesses also use internal demand forecasting to highlight areas of optimization. If successful, this can increase overall productivity.

External

Rather than calculating internal capacity, external demand forecasting focuses on the surrounding landscape. For example, can the market support another competitor? If so, what market share is feasible? External demand forecasting also considers the acquisition of raw materials and other necessary goods.

Artificial intelligence

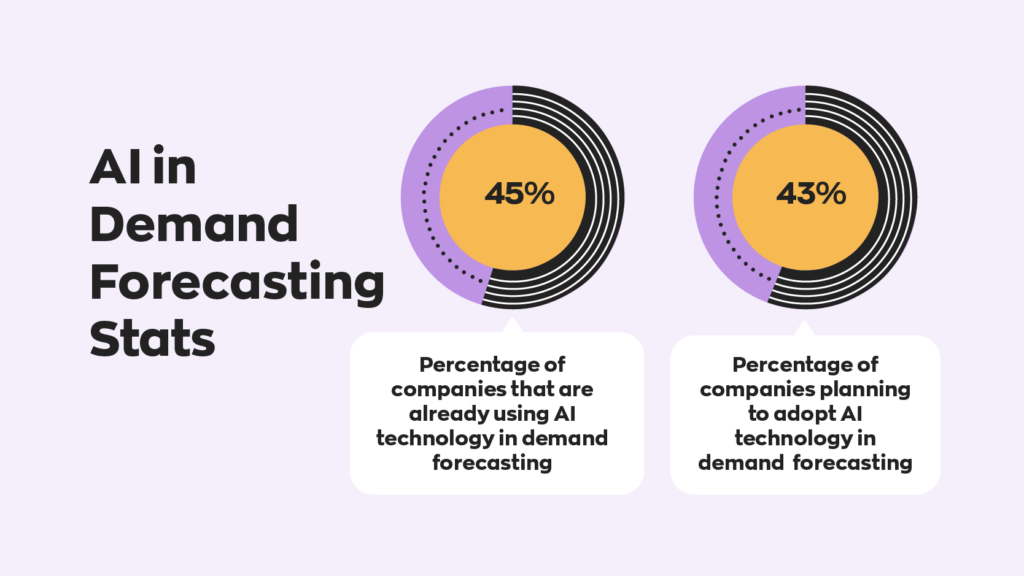

The newest one on this list. The term “artificial intelligence (AI) demand forecasting” may seem like a bit of a gimmick, but the truth is that AI has a lot to offer when it comes to forecasting demand. While all the prior forecasting methods require humans to collect data, that data still needs to be processed by computers.

AI forecasting takes it one step further and uses AI technology to identify common trends in the information. These aren’t just from start-ups, either. IBM, for example, offers an AI demand forecasting system of its own.

The benefits of demand forecasting

Correctly forecasting demand brings many benefits, the most obvious of which is optimizing the supply chain. This, in turn, decreases overhead costs and increases profit. How? It’s simple.

Retailers and manufacturers alike usually purchase goods and materials from other sources. This could be raw materials, individual components, or even entire products. Whatever the case, there are two immediately obvious costs: purchase price and shipping cost. But even once the product or its materials arrive at your warehouse, it continues to cost your business.

Now, on top of paying to store the product, it’s also taking up space that could be used to hold another product. It could be a worse-selling product, or it could be a better-selling one. If a better-selling one could take its place, you’re effectively losing money. These expenses are known as inventory carrying costs.

Demand forecasting aims to solve this problem by purchasing enough inventory to prevent stockouts altogether. This saves on warehouse costs and leads to an overall revenue increase.

The risks of demand forecasting

All the different types of demand forecasting we mentioned before work off of data. And a lot of it. Feeding these models the wrong data can lead to disastrous results. But sometimes, there’s just not enough data to work off of for an accurate prediction. This is especially true for new businesses in new industries. It’s why more and more are turning to software and AI solutions.

Our software inFlow, for example, can create various reports with the click of a button. We even integrate with Easy Insights for our customers who want to take their data analytics to the next level. Connecting your inFlow account to Easy Insights lets you assemble custom dashboards to include charts, tables, maps, and more!

Another way to enhance your forecasting is to integrate StockTrim with inFlow; StockTrim’s machine‑learning models analyze your history and produce accurate future demand projections.

How to forecast demand

Insights gained through demand forecasting can inform key decisions about inventory, staffing, budgeting, and other needs. Inaccurate forecasting can result in misguided strategies, financial losses, and missed opportunities, so it’s essential to follow the right steps:

- Define your objectives: These should include what you are forecasting (product sales, service usage, etc.), why you are forecasting, and your estimated timeframe for completing the forecast.

- Gather data: Data used for demand forecasting typically includes historical sales data, market trends, economic indicators, and customer demographics.

- Choose a forecasting model: Decide between a qualitative or quantitative forecasting model. Quantitative models rely heavily on historical data, while qualitative models may be more effective if data is limited.

- Analyze data: Analyze the data for seasonal, geographic, demographic, and product-related trends.

- Generate forecast: Use your chosen forecasting model to project future demand.

- Monitor forecast: Track actual performance to see how it compares to your forecast. Adjust the forecast periodically as conditions change.

By adhering to this process, businesses can create precise forecasts that support initiatives such as dynamic pricing strategies, marketing campaigns, and capacity planning — ultimately leading to a competitive advantage.

Commonly used demand forecasting methods

Given just how different some industries are, there are a few different methods used to forecast demand. Organizations must choose a demand forecasting method that suits their needs and goals. Here are some of the most widely used demand forecasting methods:

Sales team estimates

At the end of the day, the sales team has the most direct contact with customers. They see and hear positive feedback and complaints, but most importantly, they see first-hand how customers interact with products. This makes their input valuable. While perhaps not as efficient as a computer, they can also create their own demand forecast.

Trend projections

This method of forecasting works off of previous sales trends. When sales were highest, when they were lowest, when they took place, and so on. While simple and reliable, filtering out outliers where sales were too high or too low is essential.

Market research

Market research is usually based on data from customer surveys. It costs a lot to distribute these surveys and crunch the numbers, but it’s also very rewarding. It can provide unique insights into things like target demographics and other factors that numbers don’t tell.

Delphi method

The Delphi method is complicated. And, unlike other methods, it relies heavily on human input. Under the Delphi method, a business consults several demand forecasting experts. They then aggregate the responses and use them to formulate another set of questions and repeat this process until they reach a consensus.

Not every business is suited for demand forecasting

Remember, demand forecasting is just one of many tools. And not every tool can be used for every job. Some industries move so quickly that data is too irregular to reveal any useful patterns. Others are so niche that their sales are always inconsistent. That said, if your business can use demand forecasting, you really should. It offers a plethora of benefits over a wide range of areas.

0 Comments