Once you’ve decided to invest in a barcode system, (and you really should!) one of the most important aspects of that system will be the type of barcode or price scanner you choose to use. We won’t dig into the really technical details of different systems right now (there are plenty of other articles on that), but this article will make the case for the type of of scanner to purchase for your small business’ needs.

If you’re interested in a more in-depth look at how you can get started barcoding your small business be sure to checkout our Ultimate Barcoding Guide. It covers scanners, printers, and everything else barcode related!

Types of barcode scanner technology

There are four main technologies used for actually scanning and identifying barcodes:

1. Pen / wand barcode scanners

You won’t find these scanners in most smaller businesses because of the way they read barcodes. With a pen or wand you end up having to run the tip of the scanner over the whole length of the barcode, much like you would use a highlighter on a piece of paper. This means that these types of scanners actually take a little longer to use, especially for transactions with multiple products.

2. Stationary / embedded / in-counter price scanners

These types of scanners are more industrial or big-box retail oriented, and they’re usually lot more expensive as a result (with costs ranging from hundreds to thousands of dollars). If you’re just starting your small business your wallet will hurt when you think about these, but they’re good to at least have on your radar. They won’t help you with a manual count of your warehouse inventory, but they are the scanners to beat when it comes to checkout speed at grocery stores or businesses that sell a lot of smaller items.

3. Handheld (pistol-grip) barcode scanners

CCD, linear image scanners, and laser scanners are three different types of technologies, but they all read basic barcodes. CCD scanners are short-range, Lasers are probably the most common type and can have much longer ranges (enough to reach the top of a warehouse shelf), and linear image scanners actually take pictures of barcodes and analyze them (for better accuracy).

You’ve probably seen a lot of handheld price scanners in business both big and small because they’re fast enough to scan a lot of items quickly at checkout, but they’re also maneuverable enough that you can also scan larger items that may not fit on a business counter. These are the scanners most small businesses should probably start out with, since you can usually pick up a single price scanner for under $100 (although prices can definitely go much higher).

Wired vs. wireless barcode scanners

Aside from the type of scanning technology, another important factor in purchasing a scanner is deciding on whether you’d like a wired or wireless. For the purposes of this article, we’ll limit our scope to handheld scanners.

Wireless scanners can seem like the new hotness and the obvious superior option to wired scanners because they help keep your setup leaner and cleaner. A lack of wires means fewer things to get tangled, and more flexibility at your checkout area or warehouse. However, With Wireless Capability comes Great Responsibility. Well, at least a little extra responsibility.

Wireless scanners will need batteries (often several to maintain a good up time), so that is a bit of added investment and complication. The other factor to consider is that wireless technology can be fallible. Wireless scanners communicate over specific frequencies (usually 2.4 GHz) using Wi-Fi or Bluetooth, and these signals can be interrupted if you are too far from the receiver, or if there are too many objects between you and the receiver. If you really need the advantages of a wireless system, it’s smart to do a test run with a single unit to see how it performs at your actual office or warehouse.

If you don’t need the extra flexibility that a wireless system provides, a wired barcode scanner can bethe more affordable and reliable option. Older scanners may use the Serial port on your computer, so you’ll require two cables for them: one for communicating with the computer, and another to supply power. However, if you use a “keyboard wedge” scanner (which uses the PS/2 port) or a USB scanner, you’ll only require a single cable for both power and data.

Although you will have to deal with cable management, wired scanners have a 100% uptime and you won’t have to worry about any extra complications while you work: as long as the cable is plugged in, you’re all set. We sell our own durable and colorful USB scanners at inFlowShop.com, but you can also find a very wide selection at sites like BarcodeInc.com or Amazon.

You also need barcode scanner software

Whichever scanner you decide to choose, think of the cost of the hardware as an investment in your own efficiency. You’ll save time and effort with every scan and all of those saved seconds will add up each day.

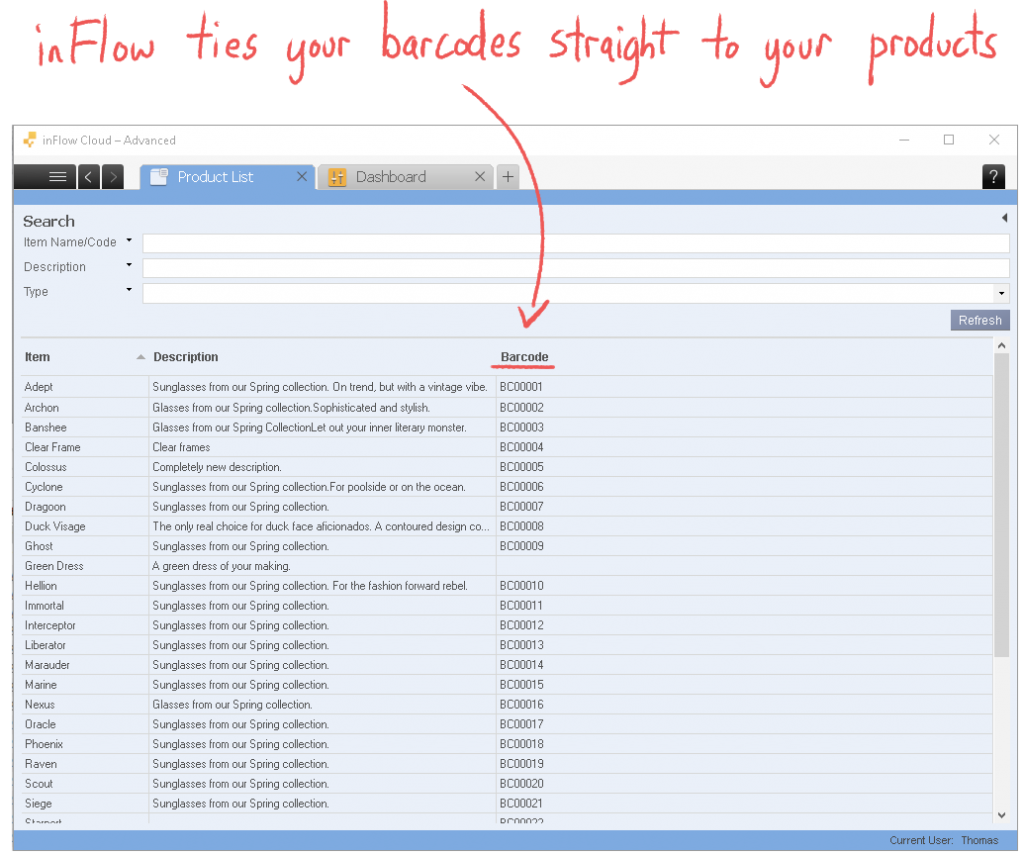

You’ll also want to use software that can read barcode scanners and tie them to products. inFlow Inventory was designed with scanners in mind, so you can scan products straight onto sales orders or just for quick stock adjustments.

Good eveining Thomas,

We manufacture, wholesale and retail our custom jewelry. Vadavas. com and want to introduce very small barcodes to our jewelry. I cannot seem to find lables small enogh (Dymo) that can work for us. Do you know if there is a way we can place several barcodes on 1 lable?

As we want to lable all merchandise produced from our small warehouse and introduce it into the store what do you reommend?

Please let me know,

Danny

Hi Danny, I haven’t printed jewelry labels here at the office myself, but there do seem to be Dymo-compatible jewelry labels from quick Googling: https://www.uline.ca/Product/Detail/S-18476/Dymo-Labelwriters-and-Labels/Dymo-Price-Tag-Mini-Printer-Labels-White-Paper-7-8-x-15-16?pricode=YA510&gadtype=pla&id=S-18476&gclid=EAIaIQobChMIzdug0f6v1wIV3rXACh1HqQZ4EAQYASABEgLbQPD_BwE&gclsrc=aw.ds

As for fitting lots of information onto a label, unfortunately that’s mainly trial and error. If there isn’t enough space or the font isn’t small enough, the text may bleed onto the next label.

I have Christmas stores with thousands of small items that I bring to different schools. Several schools are running the sale at the same time. the items already have bar codes on them. I am trying to find a way to have the cavaliers scan the items at checkout, while totaling the money due from the customer. I was wondering if there are any handheld scanners that I can program the UPC codes with prices directly into the devices? I think that would be the easiest.

Hi Mary,

There are some high-end barcode scanners that have Android or Windows computers built into the scanners, but these usually run in the hundreds of dollars per scanner.

These kinds of scanners are usually used at high-volume retail locations. They’re built to last, but they’re pricey.

Honeywell or Zebra are the brands that come to mind there, so that could be a good place to start looking.

If you’re not on the market for one of the higher end scanners mentioned above, then you could run a test with a barcode scanner and a laptop running inFlow Inventory.

That computer would run inventory software which translates the barcode -> Item and price.

inFLow works by holding all the information on your item names, prices, and barcodes.

With that information in the system, it’s just a matter of scanning items onto a sales order and the appropriate totals will show up.

This demo is a little older, but it does show you how using barcodes sales orders would save time and show the totals instantly: https://www.youtube.com/watch?v=1fSOUn5TKHc

Hope that helps!

Article Feedback*how do i have barcodes

Hi Tanaka, sorry could you let me know a bit more detail about your question?

If you’re wondering how to create barcodes, we have a separate article on that here: https://www.inflowinventory.com/blog/create-your-own-barcodes/

Hello Thomas,

I have a small business that drop ships most of our sales though third party warehouses. However we have a small factory that produces dozens of products that we stock as on hand inventory. We also have many returned items. My goal is to barcode all of the inventory that is in our warehouse.

I need a system that can log in new inventory and make adjustments for sales and returns. Will yours do it and how do I get it?

Hi Steve, thanks for getting in touch!

I believe we do have the features right now that could help you to barcode all of the existing product in your warehouse, as inFLow Cloud can print labels for current stock straight to DYMO label printers. Our sales orders can also process sales and returns (and the inventory movement is tracked as well).

I’ve forwarded your question to our support team so they can tell you in detail whether inFlow really fits your needs, but in case you’d like to try inFlow right away, you can sign up for a free trial at https://www.inflowinventory.com/

I have a small business. I sell 3 things 1 Blanket Babies ( Patton pending)

2 ladies wraps

3 custom earrings

I’m trying to figure out the best way to keep up with inventory as I buy and sell the items

What do you recommend?

Hi Sandra! It sounds like our software is actually a perfect fit for a business like yours. inFlow can help you track your purchases and sales, and also keep track of different kinds of items. You can check out our intro video here: https://youtu.be/x70A2JV1j64.

If you have any other questions, you can start a chat with us from the bottom-right area of our page. We’re online from 10am–5:30pm EST!

please I am a technician, I want you enlightenment on how to set up a store product barcode and how to connect it to a computer .

for quick sum up of goods and for remaining stock.

Hi Joe,

We’ve got a post on how to create or register barcodes for products here: https://www.inflowinventory.com/blog/create-your-own-barcodes/

And in terms of connecting them to a computer, that really depends on the software you’re using. If you use inFlow to manage orders and inventory, we’ve got a quick article on how to add barcodes to our software here: https://www.inflowinventory.com/support/article/49222654/how-do-i-use-a-barcode-scanner-with-inflow/

Once inFlow is able to recognize your barcodes you’ll be able to scan items in to do things like stock counts and receiving incoming orders.

really support your information about scanner

Thank you, Nandalal Chapagai!

Enquiry.

How much is this barcode system?

Hi YS, you can always see our latest pricing at https://www.inflowinventory.com/software-pricing. We offer monthly and annual plans.

Will your scanner system work with Shopkeep?

Hi Thomas! I have a small business selling my own designs on t-shirts I print myself at a flea market. I have about 12 different designs, 10 different colors and sizes varying from 6months to XXXLs with a volume of sales about 20,000 shirts a year. I am interested in putting barcodes on my shirts so at the end of the day I can replace what I sold (right now I manually write down every single shirt I sell). I am not interested in using it to place orders and so far. Also, is there a way I can buy the software to install in my computer and be independent from inflowinventory.com?

Thanks for your help!

Hello,

I just started my own small business. We buy pallets of merchandise from varies stores such as: Home depot, lowes, walmart and even target. I am looking for something that will scan the barcodes of items we have and tell me how much they sell in stores so i am able to put it in my computer and come up with my personal price. Is there a scanner that does that? Thanks for any help.

Hi Cinthia, sorry for the late reply. I think that sounds more like an app than strictly a hardware scanner. For example, there’s an app called ShopSavvy that you can get on iOS and Android that will do what you’re asking. Smartphone cameras aren’t as fast as real laser barcode scanners, but they still get the job done.

Hi Thomas,

I own an Estate Sale company. Estate Sales are similar to garage sales except it’s the whole house and garage, everything is for sale. I am looking for a device or digital system that will scan price tags and total the prices of each item and then add tax and also have the option to apply a 10% or 50% discount.

I need to simplify and quicken the process of checking costumers out. Currently, when a customer is checking out they have a pile of items, each item is priced anywhere from $00.50-$1000.00. The customer will tell my staff the price on the tag and my staff will add it up on a calculator and then adds tax. This process takes a long time .

Do you know of any device or program that can do this??

Thank you!

I need an easy way to do inventory control. I get you can scan the items. I sell wine and each bottle comes with barcode. How do I count the inventory in the stoe on a regular basis

Thomas.

I was wondering in the world of barcode scanners and online auctions if there is a device and software that would allow me to scan a dvd. cd or even a record album from my collection to somewhere online for selling so that i do not have to painstakenly do it manually, from taking a photo and adding details for 500 items.

I’d like the scanner to read the barcode and load all that information for me.

thank you

daniel

Would like more details etc

Hey Varghese,

Thanks for reading! If you want to learn more about barcoding, we have a very detailed article on everything barcode related. There is an entire section on scanners you may find helpful. You can read that article here -> https://www.inflowinventory.com/blog/the-ultimate-barcoding-guide/

Hope this helps,

Jared