Key takeaways

- Order picking can account for up to 60% of total warehouse costs, making it a critical area for efficiency improvements.

- The best picking method depends on warehouse size, team structure, and inventory type—there’s no one-size-fits-all approach.

- Common methods include single picking, batch picking, zone picking, and wave picking.

- Warehouse layout optimization, such as using a street-style setup, can reduce unnecessary travel and boost efficiency.

- Emerging goods-to-person (GTP) systems minimize travel and allow vertical storage but require significant investment.

- A warehouse management software (WMS) with a built-in barcode system, such as inFlow, can further optimize picking by improving visibility, reducing errors, and enabling mobile functionality.

Effective order picking strategies for small warehouse operations are crucial for achieving the same cost savings and productivity gains as larger warehouses. Choosing the best warehouse order picking method can streamline operations and boost order fulfillment efficiency. We delve into the world of warehouse order picking methods for small and medium-sized businesses to help you make the best choices

Why is my order picking method important?

When you’re not based in the warehouse on a day-to-day basis, it can be challenging to identify areas for improvement. After all, if orders are fulfilled on time, then the system works well, right? Perhaps.

In reality, order picking costs can often be as much as 60% of the total cost of warehousing. Efficient order picking for small business warehouses is critical for controlling costs, reducing errors, and maintaining customer satisfaction.

The right picking method can also make employees’ jobs easier; an inefficient system that sees warehouse staff darting back and forth won’t lead to the best results or happy staff members.

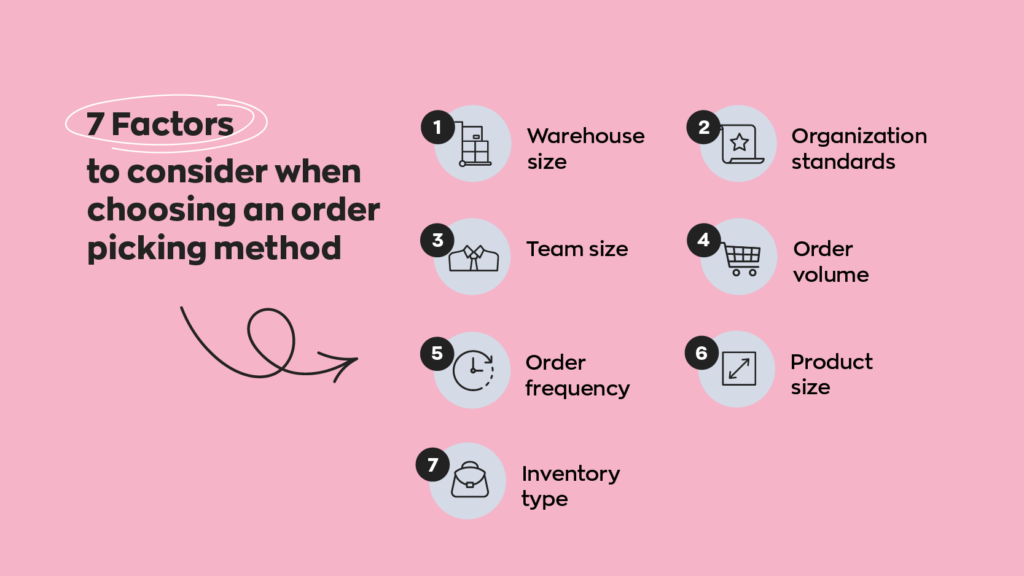

Factors to consider when choosing an order picking method

There are several popular methods for warehouse order picking and no one-size-fits-all approach. For example, the best warehouse picking method for small businesses depends on factors like warehouse space limitations, a smaller workforce, inventory type, and more. For small businesses, choosing a warehouse picking method means balancing these factors to find an approach that best fits their scale and resources.

Because of this, you might choose a different method than your competitors or partners. But even as the processes change, the aims remain the same. The right picking method will include, amongst other elements:

- Fast routes

- Well-planned processes

- Minimized room for errors

- High levels of safety

Efficient order picking for small business operations is key to keeping your customers happy and reducing shipping errors.

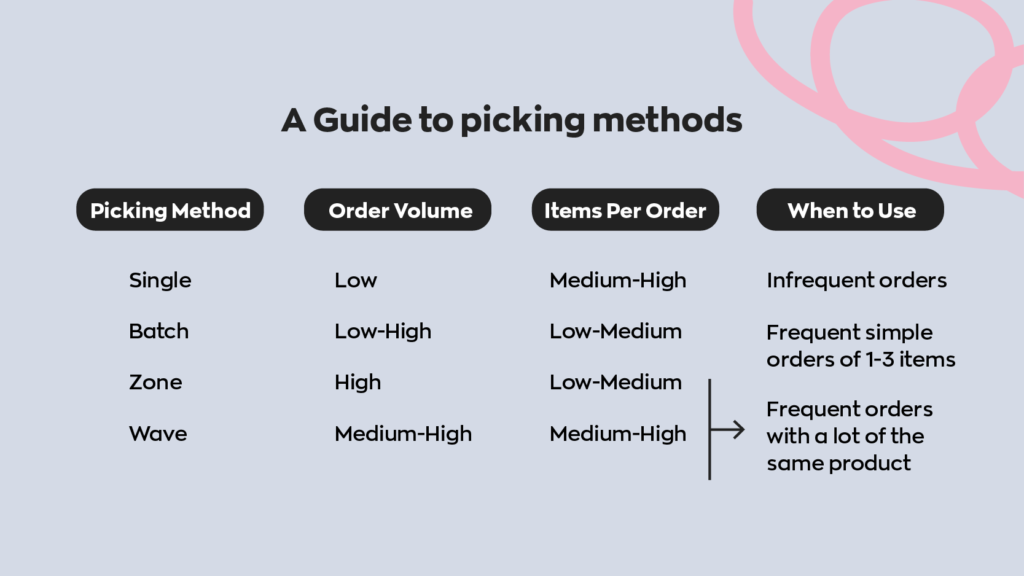

Common order picking methods

There are several warehouse picking strategies for small businesses to consider, each with its own advantages depending on your inventory and order volume. These order picking techniques for small warehouses vary in complexity and efficiency, so it’s important to match the method to the size of your operation and its needs.

Single picking

Single order picking is often considered the best order picking system for a small warehouse due to its simplicity, shorter training times, and quick implementation. In this method, when an order comes through, one person is responsible for picking every item. The employee completes the order by moving around the warehouse with a pick list.

In single order picking, employees may use barcodes that are linked to a warehouse management system (WMS) to improve accuracy and efficiency.

Batch picking

In batch order picking, the employee works on several orders at once. These batches often combine orders with items that are found close together in the warehouse. As a result, the number of trips a picker needs to make is reduced. Once the batch has been picked, the items are then sorted into the relevant orders.

Batch picking works well when orders contain similar items and when these items are relatively small in size. That way an employee can more easily pick and transport multiple items in one trip.

Zone picking

As the name suggests, this method involves dividing the warehouse into specific zones. Each employee works within their own zone, meaning that the order moves around the warehouse, but the person does not.

For large orders, zone picking can limit the distance each employee travels, saving time and energy. Employees will also get to know their zone, which may help reduce confusion and mistakes.

One disadvantage of zone picking is that there could be delays with order packing as employees wait for items to be collated from different zones.

Wave picking

With wave order picking, sets of orders are released throughout the day in ‘waves’. The aim is to ensure a consistent flow based on shipping priority, order type, and/or workforce levels. Orders are packed once all items in that wave are picked.

This can be very useful for warehouses that regularly deal with high volumes of orders. On the other hand, the system means orders may not be picked and packed straightaway, slowing down some order fulfillment times.

Optimizing order picking efficiency

Boosting efficiency in your order picking process is about working smarter, not faster. Optimizing the order picking process for small companies can lead to significant efficiency gains and fewer errors, even with a limited staff.

Small changes to your layout, training, and inventory placement can shave minutes off each pick, minutes that quickly add up to hours. The good news is that most of these improvements are easy to implement and can make a big impact on your bottom line.

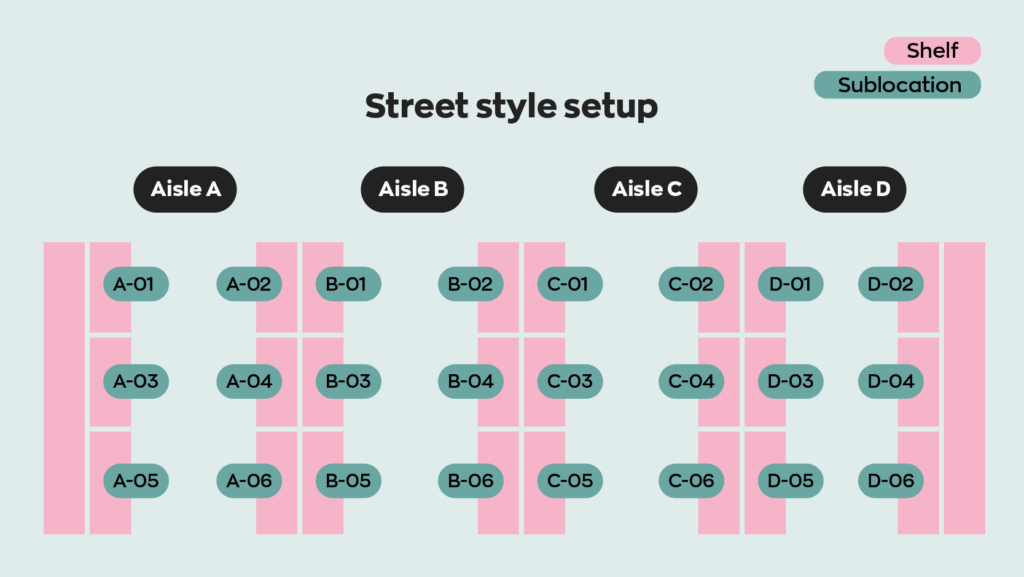

Improve warehouse layout: street-style routing

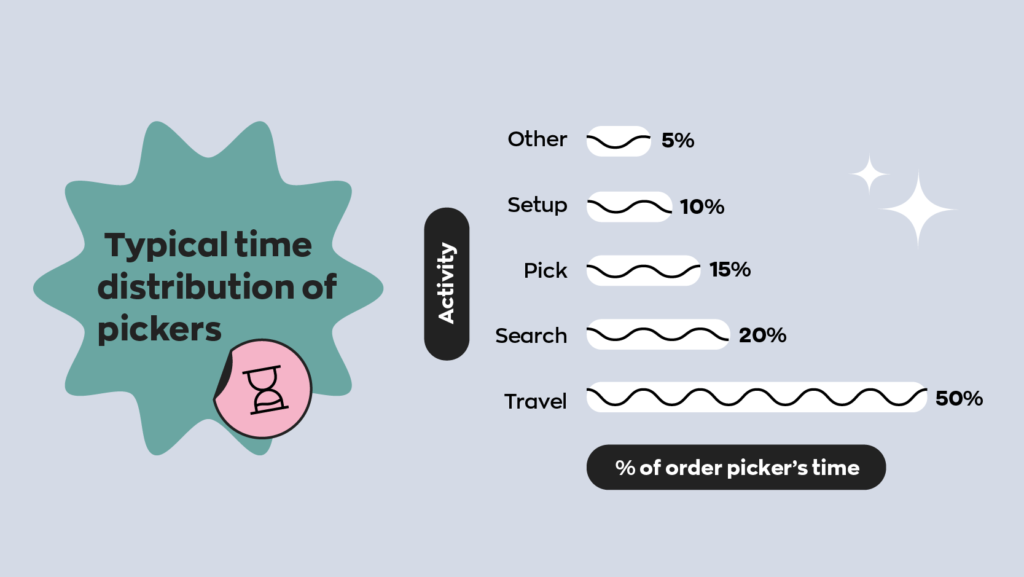

Research suggests that 50% of total order-picking time is spent on traveling. So, when a single employee is responsible for picking all — or a large part of — an order, it’s especially important to optimize the route they take. Creating a good layout is an important place to start.

Street style layouts are an example of warehouse best practice. Here, you would organize your aisles like streets. Each aisle is labeled with a marker (for example a letter of the alphabet) which works like a street name. That aisle is divided into sections and labeled in a pattern that mimics the house number system on streets in areas like North America or the UK.

Street style layouts rank among the top small business warehouse picking best practices for minimizing unnecessary travel in the aisles. You can find out in-depth information about implementing street-style picking in our recent article.

Strategic placement of high-volume SKUs

Your fastest-moving products shouldn’t be hidden in the back of your warehouse. Place your most commonly picked SKUs near packing stations and on easy-to-reach shelves. This will drastically cut down travel time and boost pick rates. With just this small adjustment, you’ll quickly see big gains in overall efficiency, especially in high-volume environments. Think of it as creating a “fast lane” for your most popular items.

Train employees on processes

The best picking system in the world won’t do you any good if your team doesn’t know how to use it. That’s why training is just as important as the process itself, and it’s not just a one-and-done task. Of course, new employees need thorough onboarding, but you should also ensure long-time staff undergo regular refreshers to stay sharp and consistent. Investing in training ensures everyone is aligned and confident, which leads to fewer errors and smoother workflows.

Regular process reviews

Once you have a system in place, the hard part is over. But the work doesn’t stop there. To keep things running smoothly, you’ll want to review its performance regularly. Have pick times improved? Are errors decreasing? Set aside time to analyze key metrics and gather feedback from your team. This way, you can identify what’s working, catch problems early, and make smart adjustments as needed.

Maintain organized shelves

Even the best possible system for your business won’t be effective without good warehouse organization. A clean, well-organized warehouse makes it easier for pickers to find what they need quickly and safely. Clear labels on products and shelves, consistent warehouse slotting, and routine maintenance go a long way. It’s all about creating an environment where accuracy and speed come naturally.

Goods-to-person order picking systems

Traditional order picking methods are person-to-goods (PTG). This works as it sounds; the employee travels to where the item is. However, this can take up time and energy, decreasing efficiency. For larger warehouses, employees may walk upwards of ten miles.

As technology develops, so do the possibilities for implementing goods-to-person (GTP) methods. For example, employees might be based at workstations, receiving items that are delivered to them via a conveyor belt system.

Using GTP order picking methods can help large facilities reduce traveling time and also allow for vertical storage options, making use of otherwise empty space that employees would struggle to reach. However, GTP solutions can be expensive to implement and so the benefits need to outweigh the costs for any business considering transitioning to these methods.

Of course, it isn’t all or nothing. Businesses using person-to-goods methods can still use technology to help them automate their workflows, including warehouse management software.

Leverage warehouse management software

When it comes to warehouse management, having the right tools at your disposal can help everything run more smoothly. Improving warehouse picking for small enterprises is often easiest with the help of a WMS, which can streamline processes and prevent mistakes.

As explained in Forbes, a warehouse management system (WMS) is a type of software that “tracks all materials and goods as they come in and go out of the warehouse” and can also create systems to help streamline picking and packing processes. This means fulfilling orders more quickly with fewer mistakes.

To reap the full benefits of your warehouse management system, it’s important to choose software that works for your business. Warehouse management software like inFlow’s lets you:

- review pick lists

- transfer stock instantly

- check stock by scanning a barcode

- optimize picking routes

- log shipments

- ….and more.

These actions can be done straight from your phone (or via a scanner if you prefer), with the option to view live information and make changes. That way, your decisions are always based on up-to-date information.

Conclusion

There’s no universal “best” picking method. What works for one warehouse might actually slow another one down. The key is to find a system that fits your team, your space, and your order volume. Whatever picking method you choose, the goal is always the same: faster picks, fewer errors, and a smoother workflow.

Remember, if you’re unsure how to choose an order picking method for a small business, start by evaluating your warehouse size, daily order volume, and the variety of products you stock. And don’t forget that your order picking method is only part of the puzzle. Good layout, smart SKU placement, regular training, and solid software are just as important.

Hi there

I have a work permit, I’m legally permitted to work in Canada, please let me know any labour job available.

I can start any time

Thank you

Hi Md.Jahed,

I would check your local listings for any job opportunities in your area. LinkedIn is also a great resource for job listings. We’re a software company that provides solutions for businesses managing their inventory, so we can’t really help you in your job search.

Best of luck,

Jared