Key takeaways

- Construction job costing involves categorizing and tracking all expenses tied to a project, including labor, materials, and overhead. It provides construction businesses greater insight into what a project actually costs.

- Job costing is very popular in the construction and field service industries because it is ideal for unique, one-off projects.

- For repetitive, standardized work, like prefabricated housing, process costing is ideal.

- Cost codes make implementing construction job costing much more manageable.

- Regular reviews comparing projected costs to actual expenses help identify issues early and avoid budget overruns.

Anyone working in the construction or field service industry knows all too well how quickly a well-planned project can turn sideways. Most of the time, the culprit is poor budgeting. One slight miscalculation in labor or material costs could cause your profit margins to dry up. That’s why the most seasoned contractors rely on construction job costing to protect their bottom line.

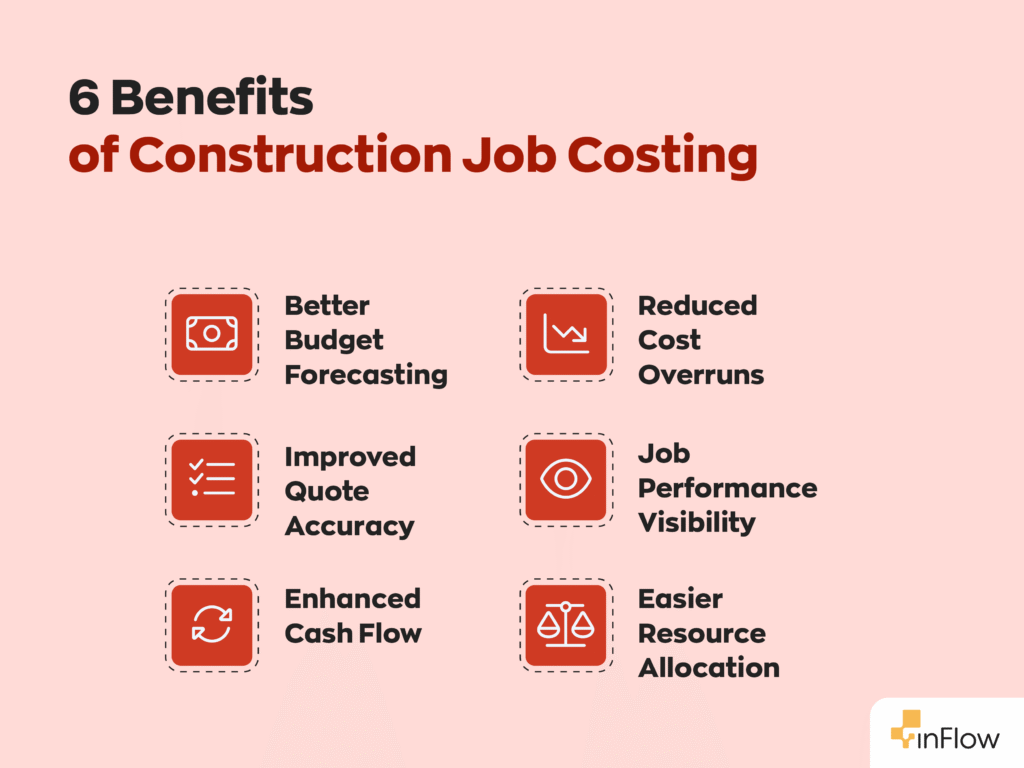

So, if you want to learn why the most successful contractors use construction job costing, this article is for you. We’ll break down what job costing is, how it compares to process costing, and how to implement your own job costing system from scratch. Whether you’re a small contractor or work within a larger field service company, construction job costing can improve your budgeting, help you provide more accurate quotes, and make more informed business decisions.

What is construction job costing?

Construction job costing refers to precisely tracking all expenses associated with a particular project. Specifically, it aims to provide a comprehensive breakdown of every cost that a job incurs. This ranges from employee wages to material costs and even certification costs.

The more accurate the breakdown, the better informed the business is. This can help guide businesses to better decision-making. It also helps them build quotes for future projects based on past budgets. This makes construction job costing an invaluable tool for predicting profitability.

Job costing vs process costing: what’s the difference?

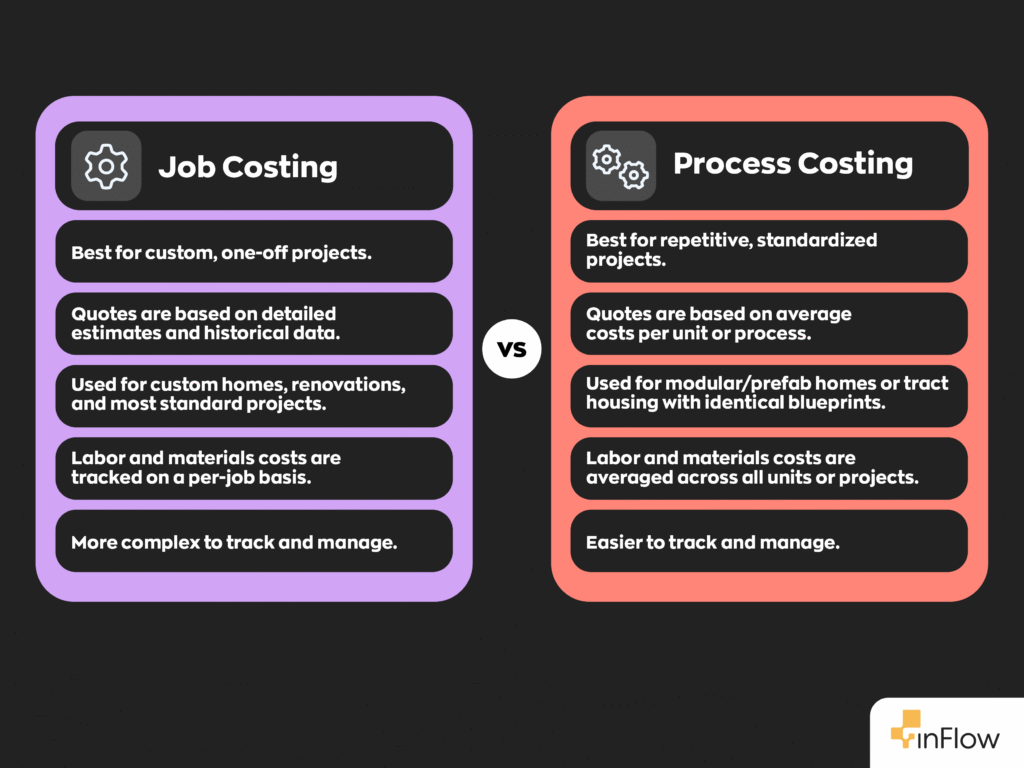

Construction job costing accounts for materials down to the final screw. It’s best for unique, one-time jobs where you need to keep close track of overhead costs. It also works in a comparatively short period.

Process costing, on the other hand, focuses on the larger costs over a longer time span. Companies use this method when the time and materials to produce individual units are known and the process is easily repeatable.

For example, let’s say you were building modular homes. Most of the work for these construction projects takes place off-site in a controlled environment. Each unit follows the same steps and requires the same amount of materials and labor to construct. This stage of construction more closely resembles a manufacturing assembly line than a traditional construction project, which is why process costing could easily be applied here.

However, no matter what type of contractor you are, I’m sure you’ll agree that those projects are the outliers, not the norm. For the most part, the amount of materials and labor necessary differs from project to project.

How to implement construction job costing

Now, admittedly, we can’t provide you with everything. The needs of every business are unique, after all. But we can provide you with a skeleton to build off of.

Setup up construction cost codes

The first thing you need to do is set up a construction cost code system. These codes help categorize costs into labor, materials, subcontractors, overhead, equipment, permits, etc. They make tracking your various expenses a lot easier.

Develop a comprehensive chart of accounts

A chart of accounts is an organizational tool used to help track financials. Set up your chart of accounts so that every expense you record aligns with your job costing system. This is where your cost codes will come into play. You can populate your chart of accounts by using your cost codes to ensure standardized cost tracking.

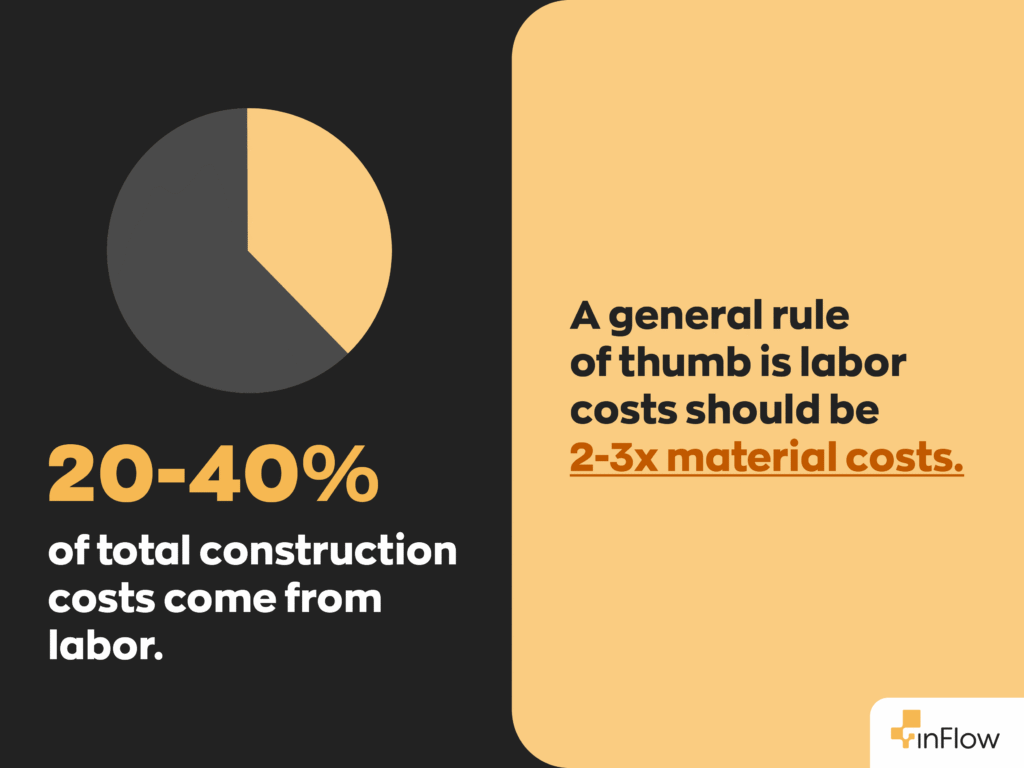

Accurately track labor costs

One of the most significant expenses for any project is labor. This is why accurately tracking labor is so essential for staying within budget. A few missed hours here and there can quickly eat away at your profits. Also, don’t forget that to calculate the true value of labor, you must factor in things like benefits and overtime.

Accurately track material costs

It’s hard to keep an accurate record of materials costs. You’ll need to order things in batches and store everything in various locations. For instance, some materials may be on your truck, others at the job site, and some in storage.

You can use field management software to make this process easier. For instance, you could use purchase orders to tie materials to specific projects, creating an easily traceable paper trail. Remember that construction projects are large and take a lot of time. As a result, swings in material prices can be particularly disruptive to the budget.

Accurately track overhead costs

Materials and labor are the most obvious expenses you’ll need to manage, but tracking your overhead costs is just as important. Overhead costs include anything you must pay to “keep the lights on,” figuratively and literally. Insurance, utilities, office rent, and permits would all fall into this category.

A simplified way of doing this would be to calculate your overhead costs for the entire year and divide that number by the amount of time a job would take. For instance, say your yearly overhead is $10,000, and you have a job that will take one week. Your overhead costs for that week would be around $192 ($10,000/52 weeks).

Conduct regular reviews

Construction projects often work on a tightly planned budget and schedule. You can’t just set it and forget it. You must review the process periodically as time goes on to ensure everything is running smoothly. Compare your forecasts with actual construction job costing numbers to see how well they match. This practice will help you catch any overspending early so you can make necessary adjustments before it’s too late.

How inFlow can help with construction job costing

If you’re one of the many businesses still using spreadsheets to track expenses, I’m here to tell you there’s a better way. Our software inFlow is packed with features to make tracking your inventory, assets, and expenses much more manageable. Here are some of the ways inFlow will help you with construction job costing:

- Perpetual inventory tracking—our system updates as you use materials, so you’ll always have a real-time view of your inventory levels.

- Historical data & reports—quickly review past job costs by looking at your historical data. You can even generate various reports to help you create more accurate quotes.

- Built-in barcode system—generate, print, and scan barcodes all inside the app. With barcodes, you can scan materials as you use them to help eliminate errors and speed up resource allocation.

- Custom fields—use our custom fields to input construction cost codes for all your inventory items.

- Software integrations—we know many businesses need more than one software solution for a well-rounded operation. That’s why we offer integrations with QuickBooks Online, Xero, Shopify, and over 95 other software solutions.

Wrapping up

And that’s it! Now you know how construction job costing works. While it might be challenging to grasp at first, the rewards are well worth the investment. Whether you’re doing a small home renovation or overseeing a large-scale development project, construction job costing will help you turn chaos into control. So, if you want to prevent runaway budgets in the future, consider giving construction job costing a try.

0 Comments