Key takeaways

- Business assets are divided into two categories: current and fixed. Current assets like inventory and packaging support short-term operations, and fixed assets like equipment and warehousing infrastructure support long-term functionality.

- Tangible warehouse assets (e.g., forklifts, racks) enable efficient storage and handling, while intangible assets (ex. logistics expertise) boost performance and customer trust.

- The asset lifecycle includes procurement, usage, maintenance, depreciation, and disposal, with each stage requiring strategic planning to maximize return on investment and minimize disruptions.

- Poor asset management increases operational risks, including equipment failures, financial inaccuracies, and inventory shortages.

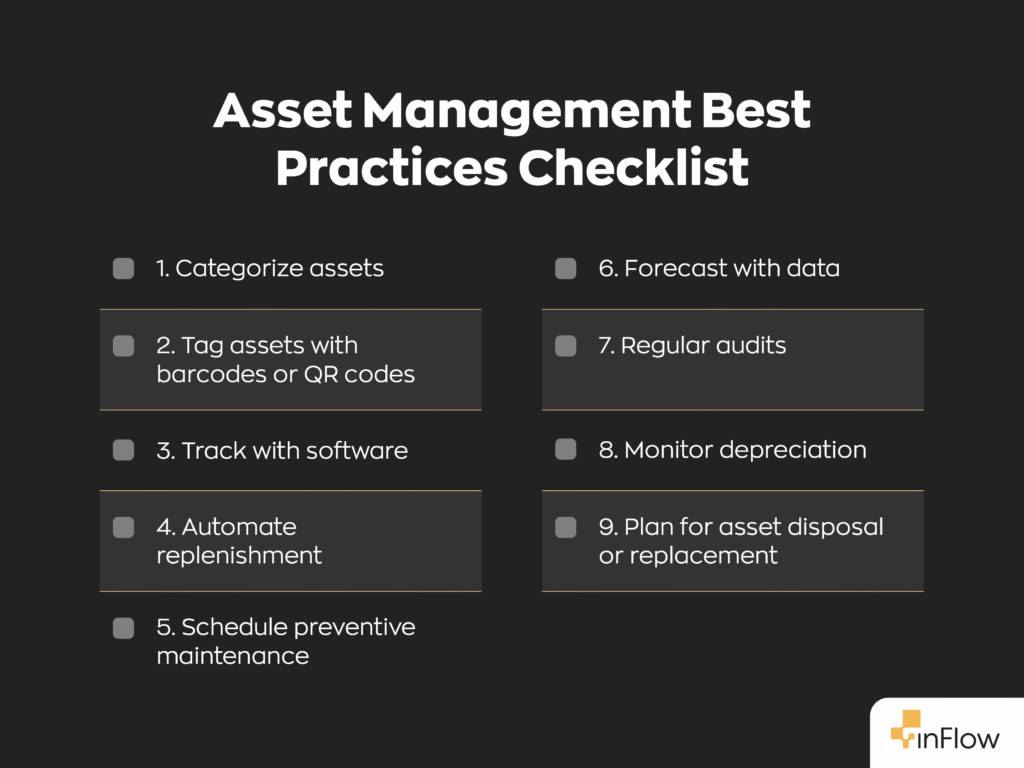

- Strategies such as asset categorization, regular audits, and automated replenishment rules help reduce losses and ensure smooth, cost-efficient operations.

- Effective asset management relies heavily on inventory software tools that provide real-time visibility, enable proactive maintenance, and improve forecasting accuracy.

Business assets are valuable resources owned by a company that contribute to its daily operations, financial reporting, and long-term planning. They’re essential for creating value, generating revenue, and ensuring sustainability and longevity. Inventory, equipment, and warehousing infrastructure are key asset types, classified as current and fixed assets, respectively.

Inventory represents goods available for sale, vital for meeting customer demand and maintaining cash flow. Equipment, such as machinery and vehicles, are necessary to produce and deliver goods. Warehousing infrastructure ensures secure goods storage and logistics optimization.

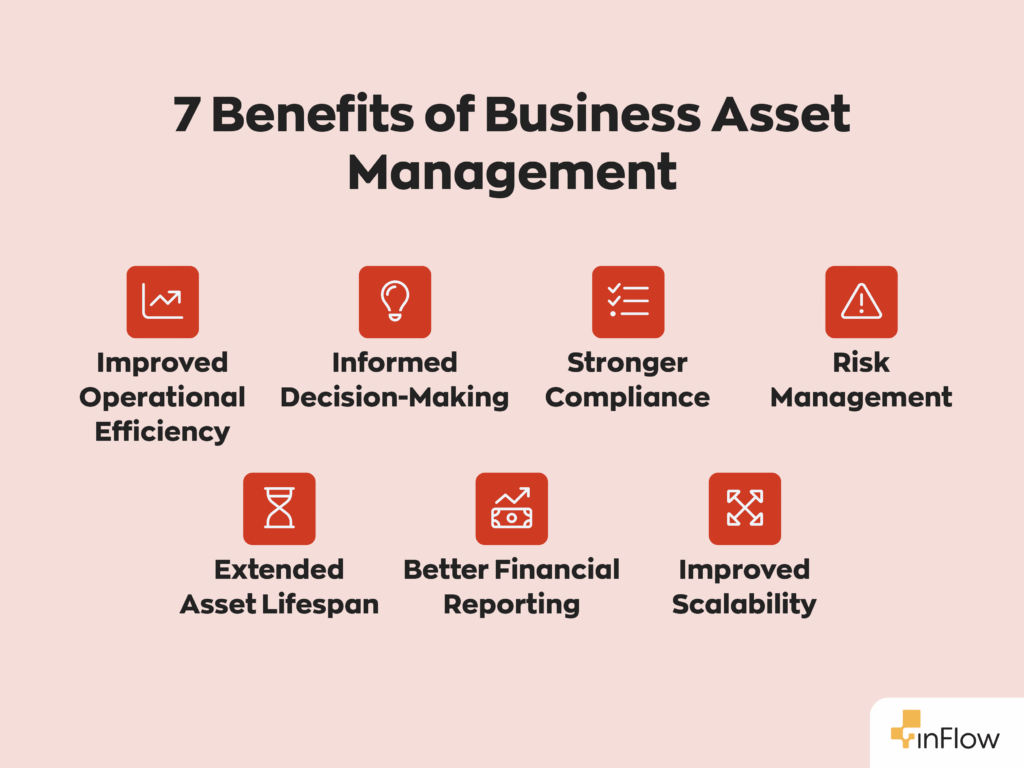

Proper tracking of these assets is crucial for accurate financial reporting, enabling businesses to assess their financial health through balance sheets. Moreover, efficient asset management facilitates strategic planning by identifying areas for investment and potential cost savings, thereby fostering long-term growth and stability.

Understanding company assets in inventory and warehousing

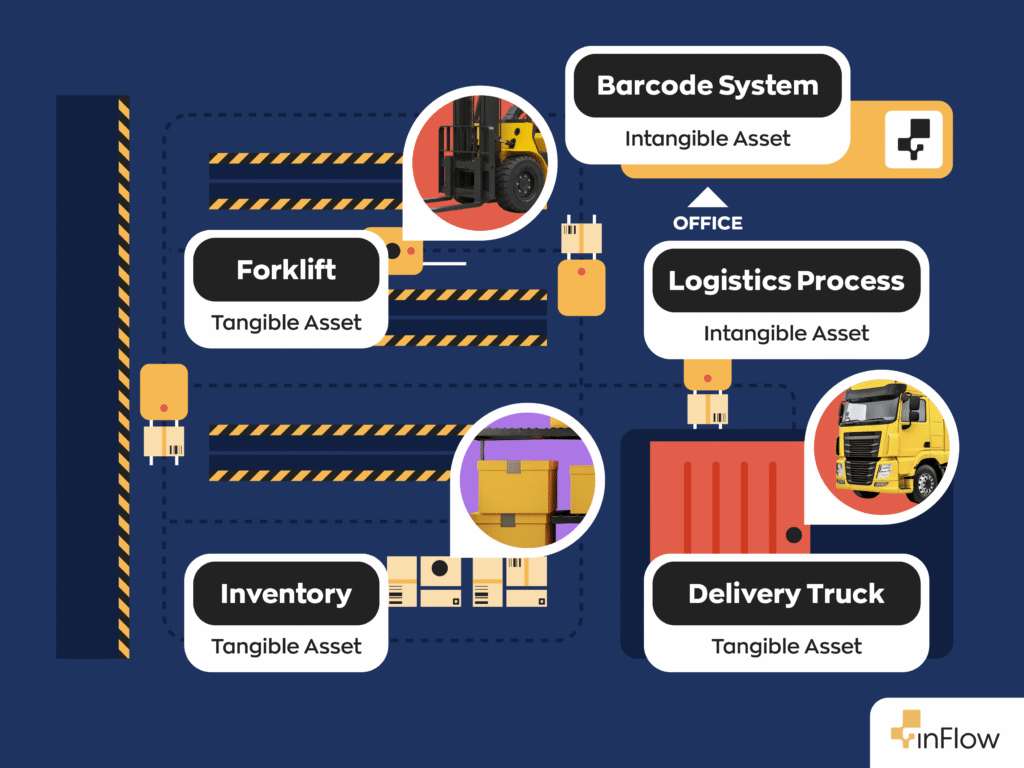

In warehousing environments, companies divide their assets into tangible and intangible categories. Tangible assets include storage racks, forklifts, and inventory. These physical assets are crucial for storing and handling goods efficiently, which directly impacts the speed and accuracy of order fulfillment. Proper use of tangible assets enhances supply chain performance by minimizing downtime and optimizing warehouse space utilization.

Intangible assets, such as company slogans and expertise, also play a crucial role. Expertise in logistics management ensures that warehousing processes are streamlined, reducing errors and maximizing throughput. A strong company slogan can enhance brand recognition and foster customer trust, indirectly boosting market presence and demand fulfillment capabilities.

Together, these assets ensure that warehousing operations are effective and contribute significantly to overall supply chain efficiency. This enables businesses to meet customer expectations swiftly and reliably while maintaining a competitive advantage.

Types of business assets

Current assets in a business — such as raw materials, finished goods, and packaging — are essential for daily operations and are expected to be converted into cash within a year. Fixed assets, including warehouse buildings and barcode scanners, are long-term resources that remain in use for extended periods, supporting the infrastructure and operational activities. Together, these assets ensure smooth distribution processes.

Manufacturing and wholesale software tools play a crucial role in asset management. They provide real-time data and analytics for employees to refer to. These tools empower businesses to efficiently organize, track, and manage assets through features like inventory monitoring, asset utilization tracking, and maintenance scheduling.

By leveraging such software, companies enhance their ability to forecast demand, minimize waste, and ensure timely replenishment, thus optimizing operational efficiency and reducing costs. This strategic approach streamlines asset management and supports better decision-making and growth opportunities.

Asset lifecycle: From acquisition to disposal

By comprehensively managing the asset lifecycle, companies can ensure they’re purchasing cost-effective assets, maintaining them properly to extend their useful life, and disposing of them responsibly at the end of their cycle. This approach contributes to overall efficiency by maximizing return on investment while minimizing unexpected downtime and maintenance costs.

Additionally, a firm grasp of the asset lifecycle aids in strategic planning, ensuring alignment with long-term business goals and facilitating budgeting for the future. By adopting a lifecycle perspective, businesses can achieve greater sustainability and agility in their asset management practices, leading to competitive advantages in their industry.

Procurement

The procurement stage of the business asset lifecycle involves acquiring assets strategically to meet the organization’s operational needs. This phase includes identifying requirements, selecting suppliers, negotiating contracts, and purchasing the goods or services.

Effective procurement makes it possible to secure quality assets at competitive prices, ensuring value for money. It requires thorough market research and a strong understanding of supply chain dynamics, but it helps to make costs more efficient and sets the stage for smooth integration into the company’s operations.

Usage

The usage stage of the business asset lifecycle focuses on deploying and using assets efficiently to support business operations. During this phase, assets are actively used to generate value, necessitating regular maintenance and monitoring to ensure optimal performance and longevity. This means never deviating from operational protocols, always scheduling routine inspections, and promptly addressing any needed adjustments or repairs. Effective management at this stage maximizes asset productivity while minimizing downtime and unexpected costs.

Maintenance

The maintenance stage is essential for preserving asset functionality and extending lifespan. It involves routine inspections, preventive maintenance, repairs, and upgrades to ensure assets operate at peak efficiency.

Regular maintenance minimizes unplanned downtime and prevents costly failures, contributing to more predictable operating expenses. With a structured maintenance schedule, businesses can optimize performance, enhance safety, and maintain compliance with industry standards. This stage also involves monitoring asset conditions and utilizing data analytics to identify potential issues, enabling proactive solutions that sustain productivity and support long-term business success.

Depreciation

Over time, business assets can become obsolete, resulting in depreciation of their value. This depreciation stage is vital for financial accounting, as it allows businesses to distribute an asset’s cost over its useful life, which in turn affects both tax calculations and financial statements. Standard depreciation methods include straight-line and declining balance, which help businesses adhere to accounting standards, maintain transparent financial reporting, and optimize their tax obligations.

Disposal

The disposal stage of the business asset lifecycle involves retiring assets that are no longer useful or cost-effective to maintain. This stage includes evaluating the asset’s condition, determining its salvage value, and deciding the most advantageous method of disposal. This could be selling, recycling, or donating.

Assets must be disposed of properly not only to maximize residual value but also to comply with relevant environmental regulations and company policies. Proper documentation and reporting during disposal are crucial for accurate financial records. They also aid in future planning and budgeting, thereby ensuring sustainable asset management practices.

Strategies for managing business assets efficiently

Effective warehouse asset management involves several best practices to ensure operational efficiency and minimize losses. Categorization of assets helps streamline storage, retrieval, and tracking processes, making inventory more accessible and organized. Regular audits are essential for verifying physical inventory against records, identifying discrepancies, and preventing losses or theft.

By automating replenishment rules, inventory levels are maintained at an optimal level, thereby reducing the risk of stockouts and excessive inventory holding costs. Inventory management software is key here. It enhances visibility across the entire supply chain, allowing inventory movements to be tracked and analyzed in real-time.

This software reduces the likelihood of misplacement or overstocking by providing accurate data and alerts. Additionally, it enables data-driven decision-making and improves forecasting accuracy, fostering more efficient and agile warehouse operations.

How asset management reduces operational risk

Asset mismanagement in high-volume warehouse or manufacturing environments significantly elevates operational risk by leading to inefficiencies and disruptions. Poorly managed assets can lead to inventory inaccuracies, resulting in stockouts or overstocking, which can halt production lines or increase holding costs.

Mismanaged assets also increase the likelihood of equipment failures. Irregular maintenance schedules and neglected asset conditions can lead to unexpected breakdowns, resulting in costly downtime and delaying order fulfillment.

Additionally, inadequate asset tracking can lead to loss, theft, or misplacement of assets. Which, in turn, affects the accuracy of financial records and compliance. By implementing effective asset management strategies, such as regular audits, maintenance schedules, and real-time inventory tracking with advanced software, businesses can mitigate these risks, ensuring smooth operations, optimized inventory levels, and enhanced financial management.

0 Comments