Key takeaways

- Barcode label protection is important because damaged or faded barcode labels can slow operations, increase costs, and harm inventory accuracy and customer satisfaction.

- UV exposure, extreme temperatures, moisture, frequent handling, abrasive surfaces, and chemicals are the most common causes of failed barcode scans.

- Synthetic materials like polypropylene and polyester offer greater durability than paper, while specialized labels handle extreme or unique conditions.

- Protective options such as UV coatings, lamination, and barcode label protectors help extend label lifespan.

- Placing labels on clean, smooth, flat surfaces and avoiding seams, curves, and high-touch areas will improve longevity and scan reliability.

- High-quality printers and scanners, along with regular test scans, ensure consistent barcode readability.

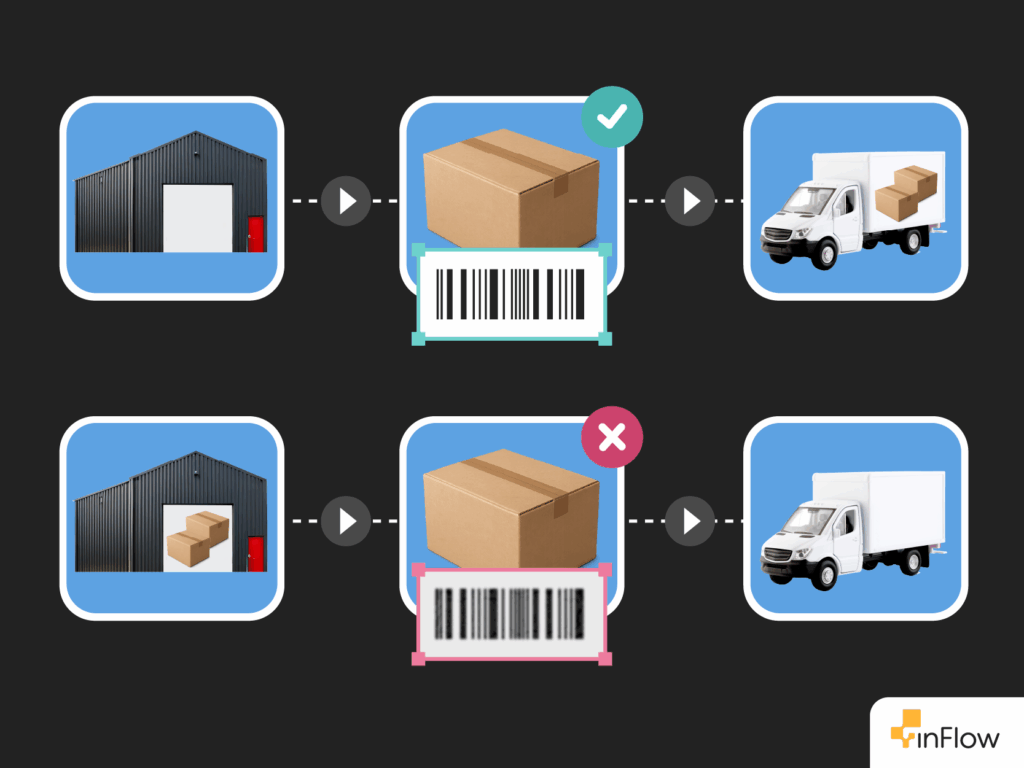

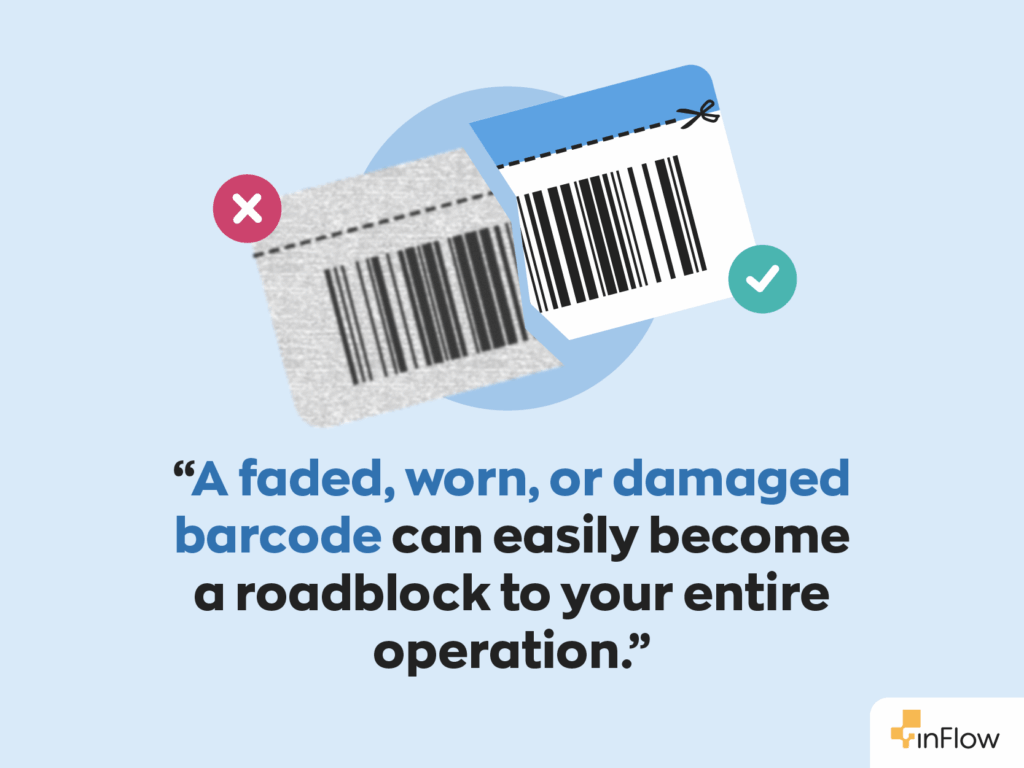

When it comes to inventory management, barcodes still reign supreme. However, their usefulness hinges on whether or not they can scan properly. Just one faded, smudged, or damaged barcode can bring your operations to a standstill, causing errors, delays, and frustrated employees.

The good news? Protecting your barcode labels doesn’t require a massive investment or complex procedures. With the right materials and proper placement techniques, you can ensure your barcodes remain scannable for years to come.

In this guide, we’ll walk you through everything you need to know about protecting your barcode labels. From choosing durable materials to proper placement best practices. So if you’re curious how to extend the life of your barcode labels, you’ve come to the right place.

Why barcode label protection matters for small businesses

Before diving into barcode label protection strategies, it’s important to understand what’s at stake. When barcode labels fail, the ripple effects can impact every aspect of your operation. Here’s how damaged or faded barcode labels can impact your business.

Operation slowdown

Unreadable barcodes force employees to enter product information manually, slowing down processes like receiving, picking, and shipping. When this happens, you’re going to lose time and open yourself up to the possibility of human error.

Increased costs

When your barcode labels fail, you’ll need to replace them, which means additional materials and labor costs. This may not seem like a big deal at first, but over time, these resources are going to add up quickly. More importantly, the downtime caused by scanning issues can cost far more than the cost to replace your barcode labels.

Customer satisfaction

Scanning issues in warehouses can lead to shipping errors and delayed orders. In retail environments, damaged barcodes can create chaos at the checkout. Both situations will result in unhappy customers.

Inventory accuracy

When barcodes become unreadable, tracking inventory becomes incredibly difficult. The ripple effect of this can lead to poor demand forecasting, which can, in turn, cause stockouts or excess inventory.

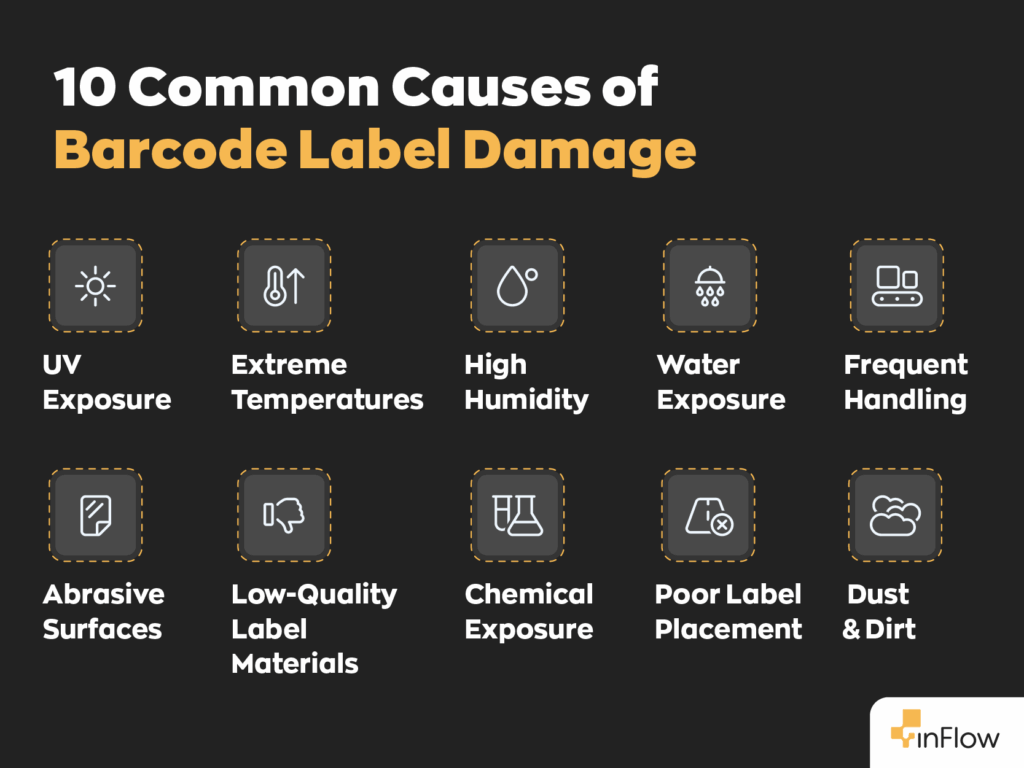

Common causes of barcode label damage

For effective barcode label protection, you’ll first need to know what the most common causes of damage are. Here are the usual suspects.

Environmental factors

- UV Exposure breaks down both ink and adhesive over time, causing labels to fade and peel. This is particularly problematic for products stored near windows or in outdoor environments.

- Extreme temperatures can weaken adhesives and cause labels to curl, crack, or fall off entirely.

- High humidity and moisture can cause labels to lose adhesion, while direct water exposure can smudge ink and make barcodes unreadable.

Physical damage

- Frequent handling of products will cause barcode labels to wear from friction and contact with other surfaces.

- Abrasive surfaces such as rough packaging materials, concrete floors, and metal shelving can scratch or tear labels during normal operations.

- Chemical exposure from cleaning products, oils, and other solutions can dissolve adhesives or damage label materials, particularly in industrial environments.

Choosing the right label materials

Protecting your barcode labels starts with assessing your specific environment and use case. Will your labels be exposed to sunlight? Extreme temperatures? Rough handling? From there, you’ll be able to choose which label material is appropriate.

Paper vs. synthetic materials

While cost-effective, paper labels are best suited for indoor environments with minimal handling. They’re lifespan is considerably shorter than other types of materials, so you should only use them for products with short shelf lives or temporary labeling.

On the other hand, synthetic materials like polypropylene and polyester labels offer superior durability and resistance to moisture, chemicals, and physical wear. This increased durability comes with a higher upfront cost, but these labels will have a much longer lifespan and provide better long-term value.

Specialized label options

If you’re storing inventory in outdoor or high-humidity environments, weatherproof labels are your best friend. These labels resist water damage and maintain their adhesion even in the most challenging environments.

For those working in industrial environments, you should consider chemical-resistant labels. These can withstand exposure to oils, solvents, and cleaning chemicals without degrading.

Cold storage environments will need specialized freezer-grade labels. The adhesive on these labels is designed to maintain their bond at low temperatures and won’t become brittle once frozen.

If you need increased security on high-value items, tamper-evident labels show clear evidence if anyone attempts to remove them. These are a great option that provides both protection and security.

Protective coatings, lamination, and label protectors

Sometimes, no matter what type of label you choose, you’re going to need some added barcode label protection. Luckily, there are options out there to add protective layers to your barcode labels, which will significantly extend their lifespan.

UV-resistant coatings

For labels exposed to sunlight or bright artificial lighting, UV-resistant coatings prevent fading and maintain barcode readability. These coatings are great for retail displays near windows, outdoor storage, and products stored in transparent containers.

Lamination

Laminating barcode labels creates a protective barrier against moisture, UV rays, and physical damage. The transparent protective film prevents scratches and makes labels easier to clean without damaging the barcode itself.

Barcode label protectors

If you want the benefits of lamination without the headache of having to laminate multiple labels, then label protectors are the next best thing. These transparent, adhesive coverings, made of durable materials like mylar or vinyl, shield printed labels from wear and tear. They guard against moisture, smudging, fading, tearing, and chemical damage, ensuring that labels remain legible over time—even in demanding environments such as warehouses, or industrial facilities.

Strategic label placement

Where you place barcode labels significantly impacts their longevity and scannability. Poor placement can expose labels to wear and tear through unnecessary handling. Always place barcode labels on a surface that will be scannable without having to move the item around.

When you apply labels, ensure the surface is clean and dry. Also, avoid dust, grease, and moisture to prevent reduced adhesion, which can cause labels to fail prematurely. Labels adhere best to smooth, flat surfaces. Avoid textured areas, seams, or curved surfaces whenever possible.

Lastly, consider the temperature of the environment. Apply labels when both the surface and atmosphere are at moderate temperatures. Extreme heat or cold during application can affect adhesive performance.

Here are some common placement mistakes to avoid:

- Placing labels over seams or edges.

- Positioning labels on curved surfaces that distort the barcode.

- Placing labels where they’ll be covered by other packaging or equipment.

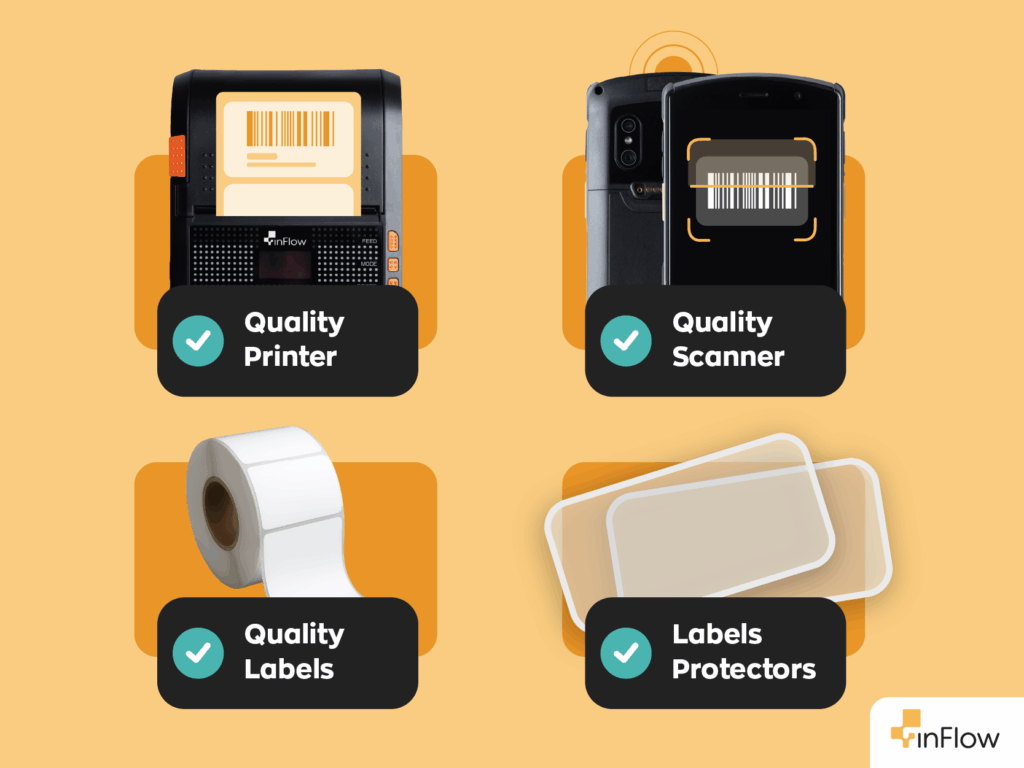

Hardware considerations

How long a barcode label will last starts with print quality. A crisp, high-contrast barcode is easier to scan accurately. Some printers produce sharper, higher-quality barcodes than others, and the same goes for scanners. Higher-quality scanners can read barcodes faster and more reliably, even when slightly faded and worn.

For dependable results, tools like the inFlow Portable Printer ensure clean, consistent barcode printing, while the inFlow Smart Scanner delivers fast, accurate scanning to keep your workflows moving smoothly.

Pro tip: Try to perform test scans on your newly printed barcodes whenever you can. Catching print issues early can save hours of troubleshooting later.

Measuring barcode label protection effectiveness

Like anything in business, you should always track the success of your barcode label protection efforts. This will help you identify what works best for your specific use case. Some key metrics to keep in mind are:

- Label lifespan—Monitor how long labels remain scannable in different environments.

- Replacement frequency—Track how often labels need replacement to identify problem areas or successful protection strategies.

- Scanning success rate—Monitor barcode scanning success rates to identify declining performance before complete failure.

Use performance data to refine your protection strategies, focusing resources on the most effective approaches for your specific needs.

Conclusion

Barcode label protection is an investment in operational efficiency, cost control, and customer satisfaction. When you choose appropriate materials and implement proper placement techniques, your businesses can ensure their barcode systems remain reliable and cost-effective. If you want to know how the right software can amplify the benefits of your barcodes, then check out inFlow. Our software has a built-in barcoding system and comes with loads of other great features, including reorder points, real-time inventory tracking, purchase and sales orders, and a whole lot more.

0 Comments